Mitsubishi L200. Manual - part 26

OIL PAN AND OIL STRAINER

ENGINE MECHANICAL

11A-32

CAUTION

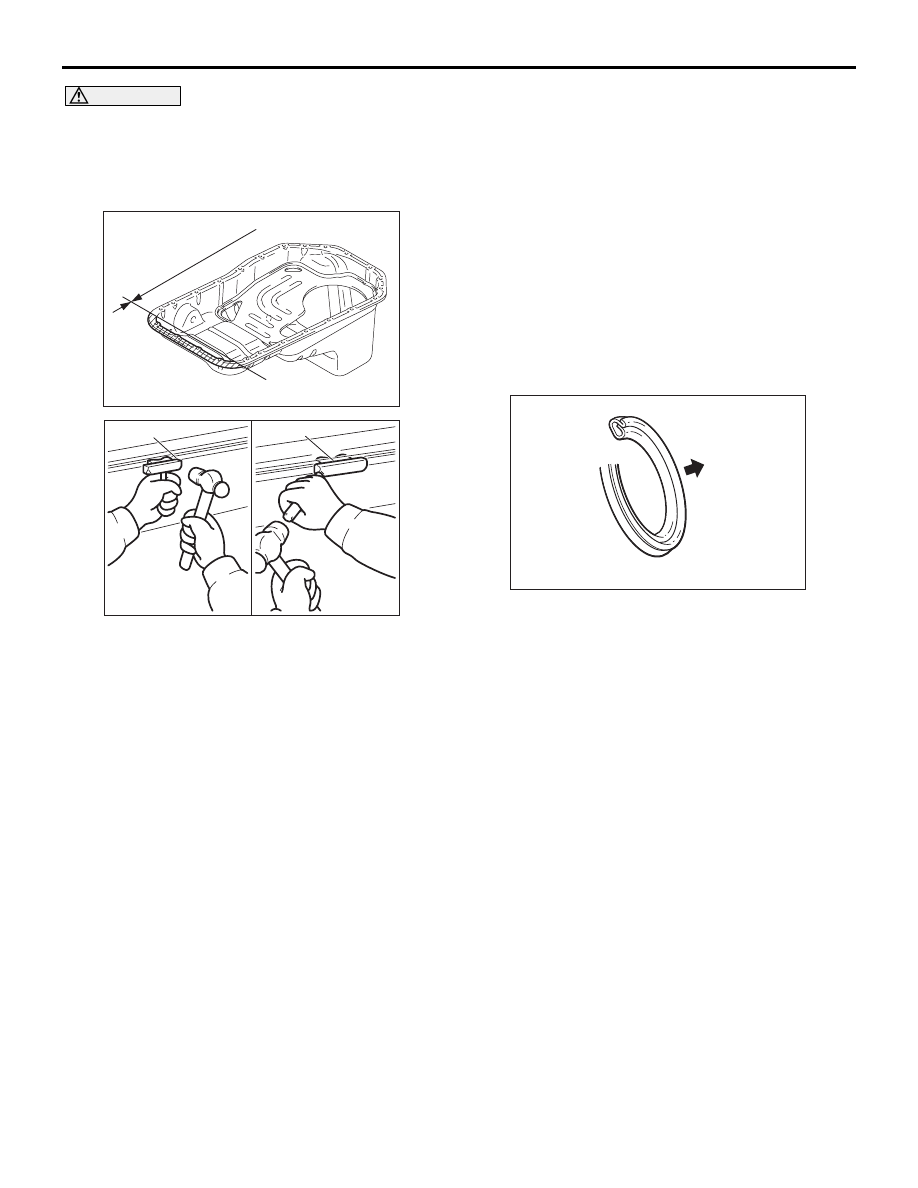

Do not use special tool oil pan FIPG cutter

(MD998727) in area A of the engine oil pan. Using

the special tool MD998727 in area A may cause

deformation of the front case because the front

case is made of aluminium.

AC504256AB

A

B

AC104547

MD998727

MD998727

AC

2. Tap special tool MD998727 into the range (B)

between the cylinder block and the engine oil pan,

and then slide the special tool MD998727

sideways.

NOTE: If any surrounding parts interfere with the

removal, there is no need to use the special tool

MD998727.

3. Remove the engine oil pan.

INSTALLATION SERVICE POINTS

>>A<< ENGINE OIL PAN GASKET INSTALLATION

Install the engine oil pan gasket so that its fluorine-

coated surface faces the cylinder block side.

>>B<< ENGINE OIL PAN INSTALLATION

1. Remove sealant from the engine oil pan and

cylinder block surfaces.

2. Install the engine oil pan.

3. Tighten the engine oil pan bolts to the specified

torque.

Tightening torque: 9.0

± 3.0 N⋅m

>>C<< ENGINE OIL PAN DRAIN PLUG GASKET

INSTALLATION

AC102325 AI

Engine oil pan side

Replace the gasket with a new gasket. Install the

new gasket in the direction shown in the illustration.

INSPECTION

M1112008400138

• Check the engine oil pan for cracks.

• Check the engine oil pan sealant-coated surface

for damage and deformation.

• Check the engine oil pan strainer for cracked,

clogged or damaged wire net and pipe.