Mitsubishi L200. Manual - part 27

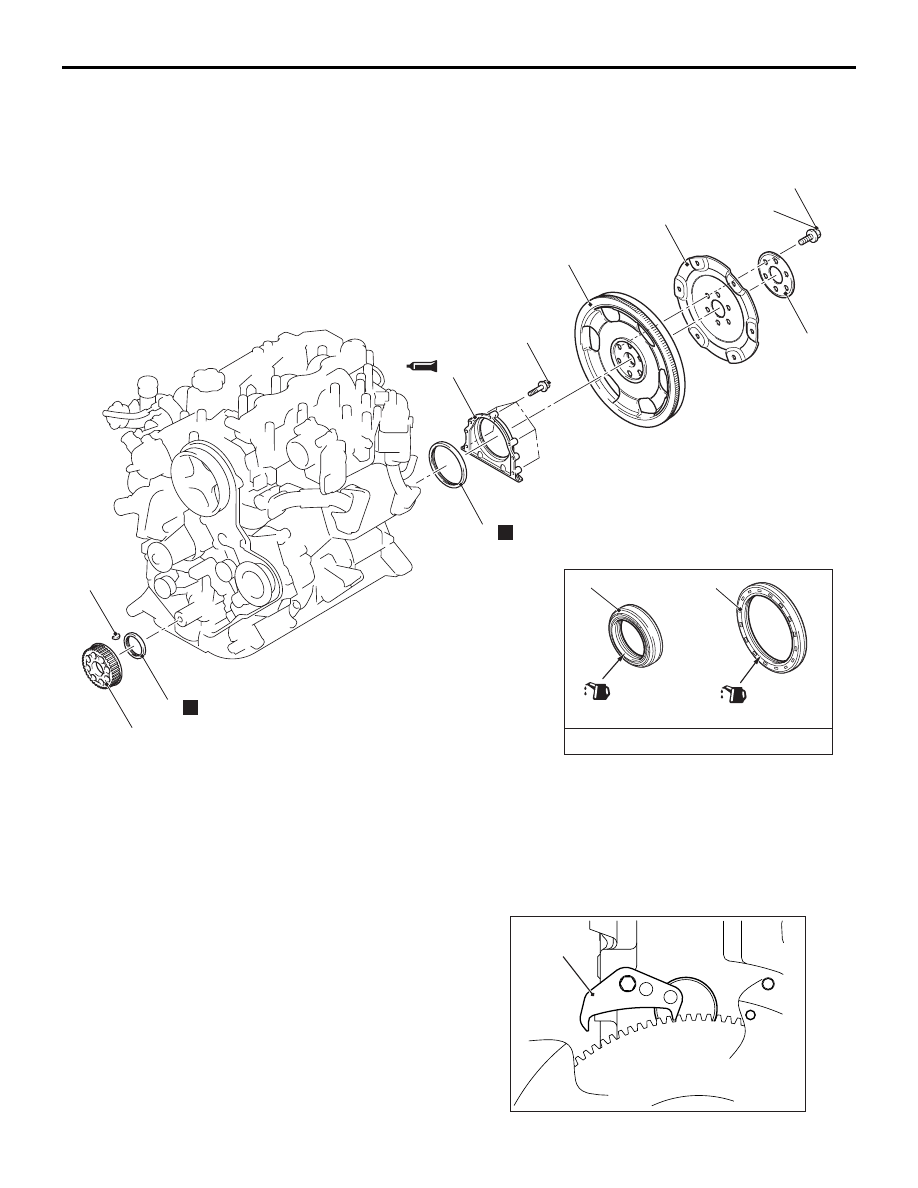

CRANKSHAFT OIL SEAL

ENGINE MECHANICAL

11A-36

REMOVAL AND INSTALLATION <A/T>

M1112003104220

ACB00630

1

2

3

N

6

135 ± 5 N·m

11 ± 1 N·m

4

5

N

7

8

9

3

9

(Lip section)

(Lip section)

Engine oil

AB

Crankshaft front oil seal removal

steps

•

Timing belt, timing belt B (Refer to

>>

E

1.

Crankshaft B sprocket

2.

Crankshaft key

>>

D

<<

3.

Crankshaft front oil seal

Crankshaft rear oil seal removal

steps

•

Transmission assembly (Refer to

GROUP 23A

− Transmission

) <4A/T>

•

Transmission assembly (Refer to

GROUP 23A

− Transmission

) <5A/T>

<<

A

>>

>>

C

<<

4.

Drive plate bolt

5.

Adapter plate

6.

Drive plate

7.

Inertia ring assembly

>>

B

8.

Oil seal case assembly

>>

A

9.

Crankshaft rear oil seal

REMOVAL SERVICE POINT

<<A>> DRIVE PLATE BOLT REMOVAL

AC802013

MB991883

AB

Crankshaft rear oil seal removal

steps (Continued)