Mazda CX 7. Manual - part 40

ON-BOARD DIAGNOSTIC [L3 WITH TC]

01-02–115

01-02

End Of Sie

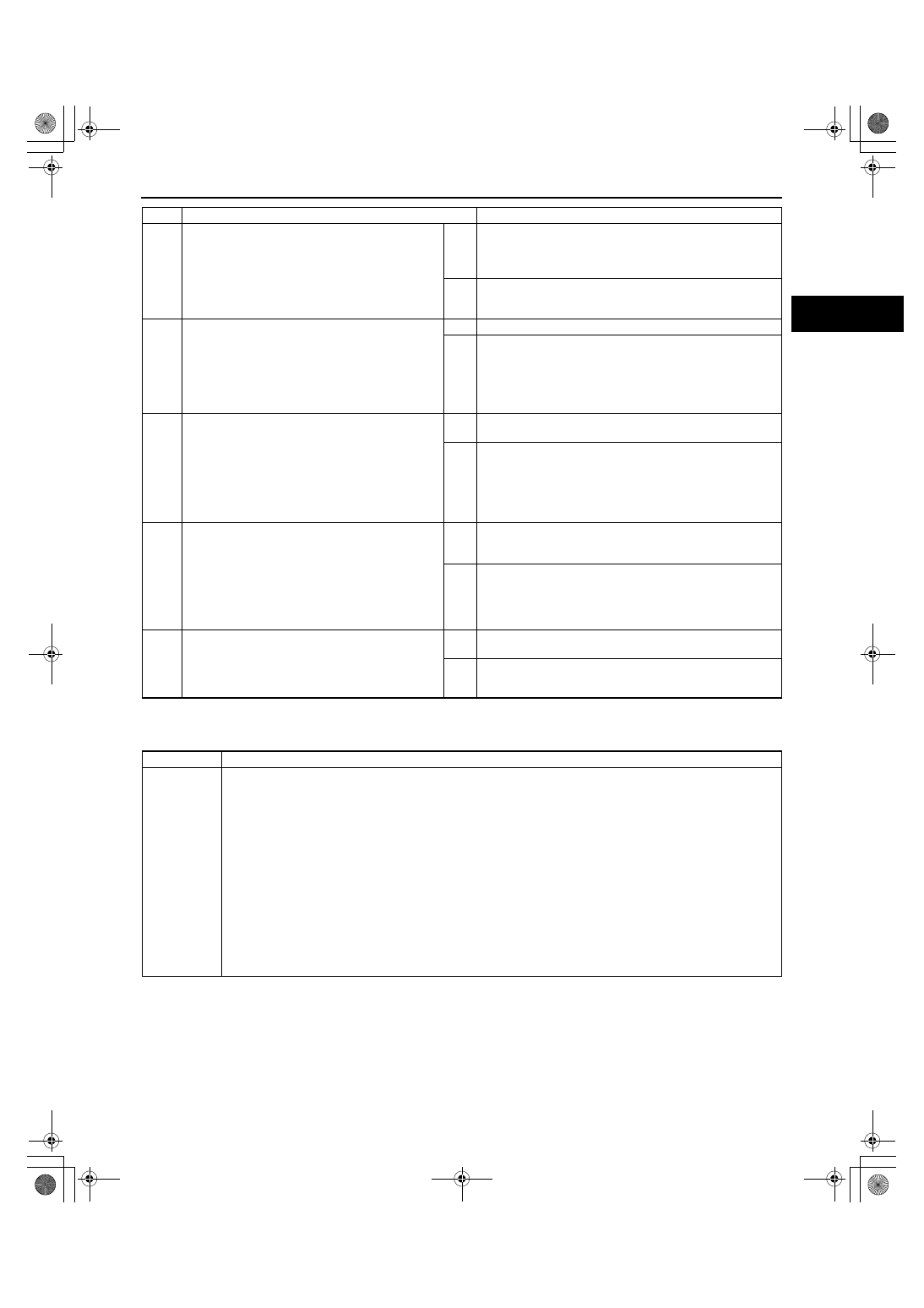

WM: DTC P03XX

DTC P0300[L3 WITH TC]

id010239806500

4

INSPECT WASTEGATE CONTROL SOLENOID

VALVE

• Inspect the wastegate control solenoid valve.

(See01-13-14 WASTEGATE CONTROL

SOLENOID VALVE INSPECTION[L3 WITH

TC].)

• Is there any malfunction?

Yes

Replace the wastegate control solenoid valve, then go to

Step 7.

(See01-13-5 INTAKE AIR SYSTEM REMOVAL/

INSTALLATION[L3 WITH TC].)

No

Go to the next step.

5

INSPECT PCM CONNECTOR FOR POOR

CONNECTION

• Turn the ignition switch off.

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/

pulled-out pins, corrosion).

• Is there any malfunction?

Yes

Repair or replace the terminal, then go to Step 7.

No

Go to the next step.

6

INSPECT WASTEGATE CONTROL SOLENOID

VALVE CONTROL CIRCUIT FOR SHORT TO

POWER SUPPLY

• Turn the ignition switch to the ON position.

• Inspect for continuity between the wastegate

control solenoid valve terminal B (wiring

harness-side) and body ground.

• Is the voltage B+?

Yes

Repair or replace the wiring harness for a possible short to

power supply, then go to the next step.

No

Go to the next step.

7

VERIFY TROUBLESHOOTING OF DTC P0246

COMPLETED

• Make sure to reconnect all disconnected

connectors.

• Clear the DTC from the PCM memory using

the M-MDS.

• Start the engine.

• Is the same DTC present?

Yes

Replace the PCM, then go to the next step.

(See01-40-6 PCM REMOVAL/INSTALLATION[L3 WITH

TC].)

No

Go to the next step.

8

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

(See01-02-10 AFTER REPAIR

PROCEDURE[L3 WITH TC].)

• Are any DTCs present?

Yes

Go to the applicable DTC troubleshooting.

(See01-02-13 DTC TABLE[L3 WITH TC].)

No

DTC troubleshooting completed.

STEP

INSPECTION

ACTION

DTC P0300

Random misfire detected

DETECTION

CONDITION

• The PCM monitors the CKP sensor input signal interval time. The PCM calculates the change of interval

time for each cylinder. If the change of interval time exceeds the preprogrammed criteria, the PCM detects

a misfire in the corresponding cylinder. While the engine is running, the PCM counts the number of misfires

that occurred at 200 crankshaft revolutions and 1,000 crankshaft revolutions and calculates a misfire

ratio for each crankshaft revolution. If the ratio exceeds the preprogrammed criteria, the PCM determines

that a misfire, which can damage the catalytic converter or affect emission performance, has occurred.

Diagnostic support note

• This is a continuous monitor (Misfire).

• The MIL illuminates if the PCM detects a misfire which affects emission performance in two consecutive

drive cycles or in one drive cycle while the DTC for the same malfunction has been stored in the PCM.

• The MIL flashes if the PCM detects a misfire which can damage the catalytic converter during the first drive

cycle.

• PENDING CODE is available if the PCM detects a misfire which affects emission performance during the

first drive cycle.

• FREEZE FRAME DATA is available.

• DTC is stored in the PCM memory.

1871-1U-06B(01-02).fm 115 ページ 2006年3月15日 水曜日 午前10時32分