Mazda CX 7. Manual - part 39

ON-BOARD DIAGNOSTIC [L3 WITH TC]

01-02–111

01-02

DTC P0234[L3 WITH TC]

id010239806200

Diagnostic procedure

End Of Sie

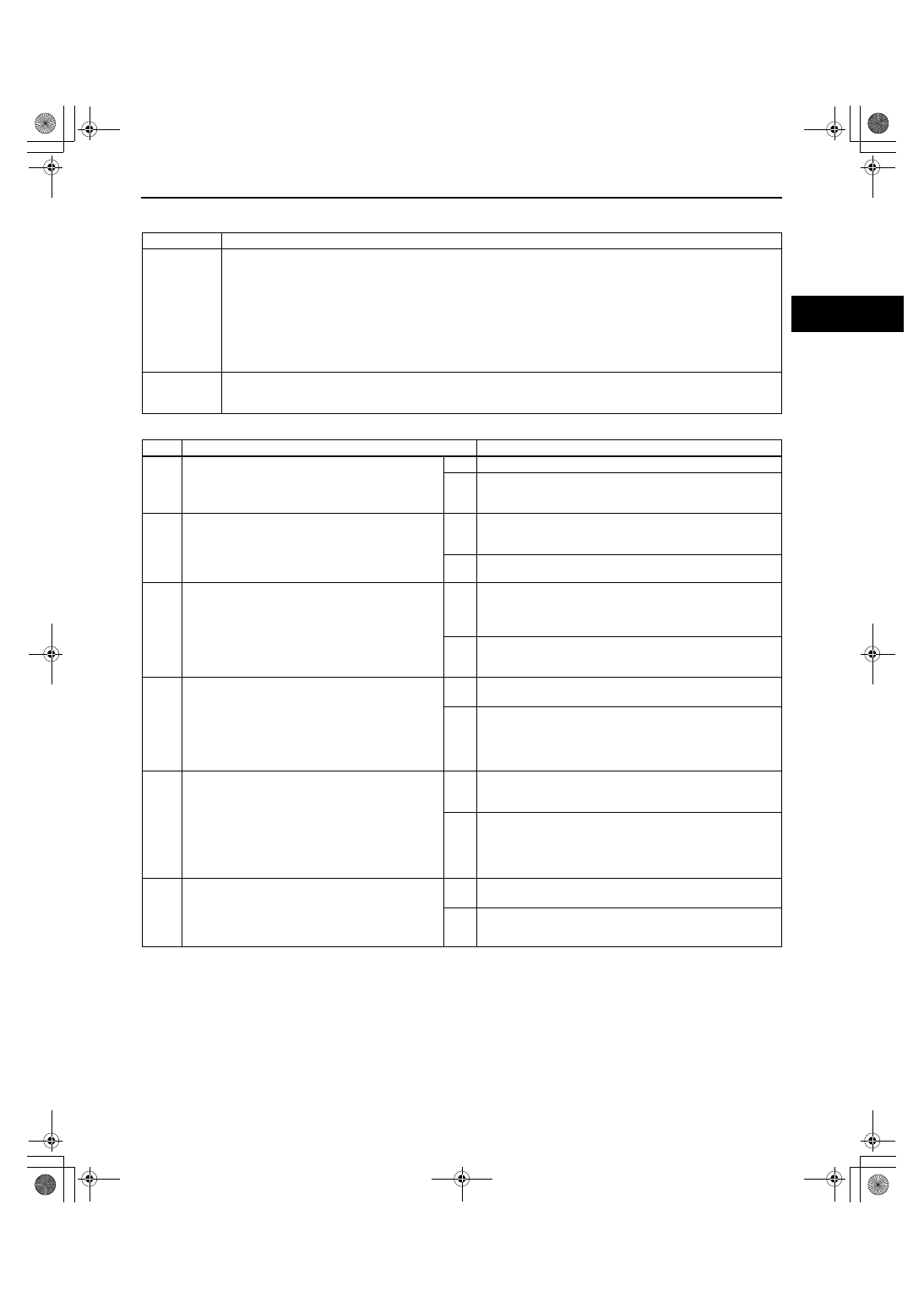

DTC P0234

Turbocharger over boost condition

DETECTION

CONDITION

• If the manifold absolute pressure or charging efficiency are more than the specification for the specified

period of time, the PCM determines that the turbocharger is in an over boost condition.

MONITORING CONDITIONS

— Engine speed is 2,000 rpm or more.

Diagnostic support note

• This is a continuous monitor (Other).

• The MIL does not illuminate.

• FREEZE FRAME DATA is not available.

• DTCs are stored in the PCM memory.

POSSIBLE

CAUSE

• Wastegate control solenoid valve malfunction

• Vacuum hose looseness or damage

• Improper installation of the vacuum hose

STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

• Has the FREEZE FRAME DATA been

recorded?

Yes

Go to the next step.

No

Record the FREEZE FRAME DATA on the repair order,

then go to the next step.

2

VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

• Verify related Service Bulletins and/or on-line

repair information availability.

• Is any related repair information available?

Yes

Perform repair or diagnosis according to the available

repair information.

• If the vehicle is not repaired, go to the next step.

No

Go to the next step.

3

INSPECT WASTEGATE CONTROL SOLENOID

VALVE

• Inspect the wastegate control solenoid valve.

(See01-13-14 WASTEGATE CONTROL

SOLENOID VALVE INSPECTION[L3 WITH

TC].)

• Is there any malfunction?

Yes

Replace the wastegate control solenoid valve, then go to

Step 5.

(See01-13-5 INTAKE AIR SYSTEM REMOVAL/

INSTALLATION[L3 WITH TC].)

No

Go to the next step.

4

INSPECT VACUUM HOSE

• Inspect the vacuum hose condition for the

following:

— Looseness

— Damage

— Improper installation

• Is there any malfunction?

Yes

Repair or replace the suspected part, then go to the next

step.

No

Go to the next step.

5

VERIFY TROUBLESHOOTING OF DTC P0234

COMPLETED

• Make sure to reconnect all the disconnected

connectors.

• Clear the DTC from the PCM memory using

the M-MDS.

• Start the engine.

• Is the same DTC present?

Yes

Replace the PCM, then go to the next step.

(See01-40-6 PCM REMOVAL/INSTALLATION[L3 WITH

TC].)

No

Go to the next step.

6

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

(See01-02-10 AFTER REPAIR

PROCEDURE[L3 WITH TC].)

• Are any DTCs present?

Yes

Go to the applicable DTC troubleshooting.

(See01-02-13 DTC TABLE[L3 WITH TC].)

No

DTC troubleshooting completed.

1871-1U-06B(01-02).fm 111 ページ 2006年3月15日 水曜日 午前10時32分