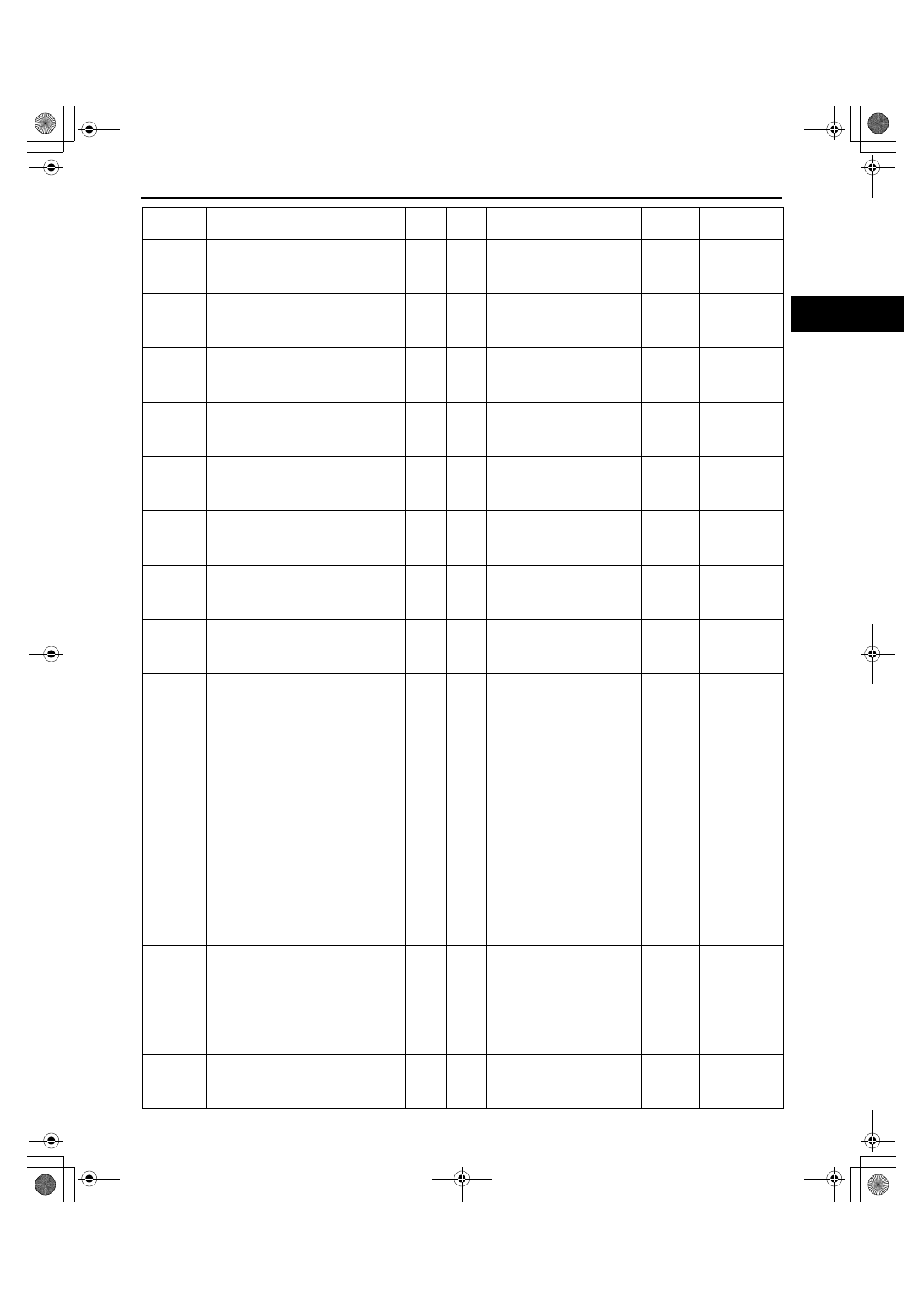

Mazda CX 7. Manual - part 16

ON-BOARD DIAGNOSTIC [L3 WITH TC]

01-02–19

01-02

P2096

Target A/F feedback system too lean

ON

2

Fuel system

C

×

(See01-02-

191 DTC

P2096[L3

WITH TC].)

P2097

Target A/F feedback system too rich

ON

2

Fuel system

C

×

(See01-02-

194 DTC

P2097[L3

WITH TC].)

P2100

Throttle actuator circuit open

ON

1

CCM

C, O, R

×

(See01-02-

197 DTC

P2100[L3

WITH TC].)

P2101

Throttle actuator circuit range/

performance

ON

1

CCM

C, R

×

(See01-02-

199 DTC

P2101[L3

WITH TC].)

P2102

Throttle actuator circuit low input

ON

1

CCM

C, O, R

×

(See01-02-

202 DTC

P2102[L3

WITH TC].)

P2103

Throttle actuator circuit high input

ON

1

CCM

C, O, R

×

(See01-02-

204 DTC

P2103[L3

WITH TC].)

P2107

Throttle actuator control module

processor problem

ON

1

CCM

C, R

×

(See01-02-

205 DTC

P2107[L3

WITH TC].)

P2108

Throttle actuator control module

performance problem

ON

1

CCM

C, R

×

(See01-02-

206 DTC

P2108[L3

WITH TC].)

P2119

Throttle actuator control throttle body

range/performance

ON

1

CCM

C, R

×

(See01-02-

207 DTC

P2119[L3

WITH TC].)

P2122

Accelerator pedal position (APP)

sensor No.1 circuit low input

ON

1

CCM

C, O, R

×

(See01-02-

208 DTC

P2122[L3

WITH TC].)

P2123

Accelerator pedal position (APP)

sensor No.1 circuit high input

ON

1

CCM

C, O, R

×

(See01-02-

210 DTC

P2123[L3

WITH TC].)

P2127

Accelerator pedal position (APP)

sensor No.2 circuit low input

ON

1

CCM

C, O, R

×

(See01-02-

212 DTC

P2127[L3

WITH TC].)

P2128

Accelerator pedal position (APP)

sensor No.2 circuit high input

ON

1

CCM

C, O, R

×

(See01-02-

214 DTC

P2128[L3

WITH TC].)

P2135

Throttle position sensor No.1/No.2

voltage correlation problem

ON

1

CCM

C, O, R

×

(See01-02-

216 DTC

P2135[L3

WITH TC].)

P2138

Accelerator pedal position (APP)

sensor No.1/No.2 voltage correlation

problem

ON

1

CCM

C, O, R

×

(See01-02-

217 DTC

P2138[L3

WITH TC].)

P2177

Fuel system too lean at off idle

ON

2

Fuel system

C, R

×

(See01-02-

218 DTC

P2177[L3

WITH TC].)

DTC No.

Condition

MIL

DC

Monitor item

Self-test

type

*2

Memory

function

Page

1871-1U-06B(01-02).fm 19 ページ 2006年3月15日 水曜日 午前10時32分