Mazda CX 7. Manual - part 17

ON-BOARD DIAGNOSTIC [L3 WITH TC]

01-02–23

01-02

End Of Sie

DTC P0012[L3 WITH TC]

id010239801700

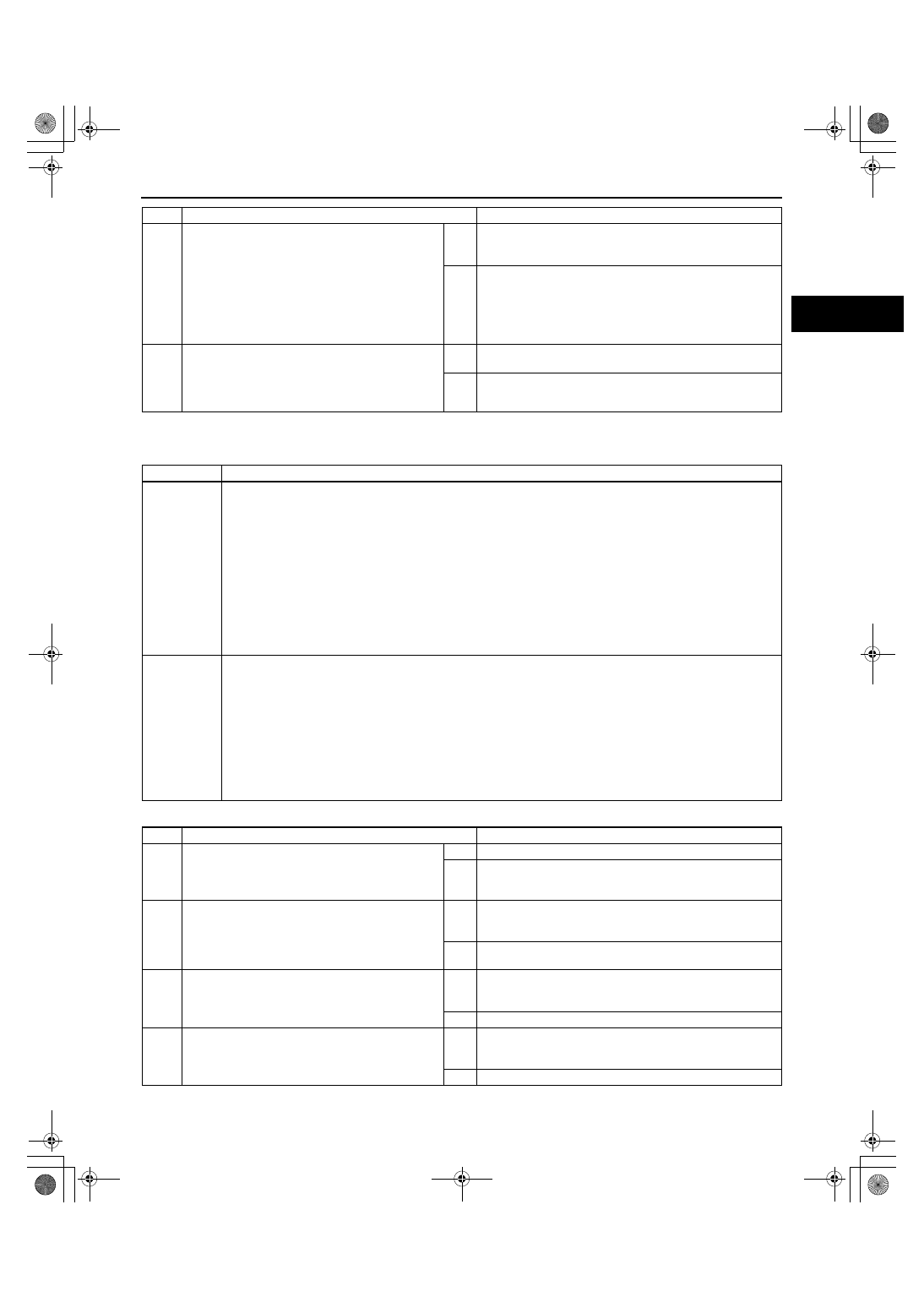

Diagnostic procedure

7

VERIFY TROUBLESHOOTING OF DTC P0011

COMPLETED

• Make sure to reconnect all the disconnected

connectors.

• Clear the DTC from the PCM memory using

the M-MDS.

• Turn the ignition switch off.

• Start the engine and warm it up completely.

• Is PENDING CODE for this DTC present?

Yes

Replace the PCM, then go to the next step.

(See 01-40-6 PCM REMOVAL/INSTALLATION[L3 WITH

TC].)

No

Go to the next step.

8

VERIFY AFTER REPAIR PROCEDURE

• Perform the “After Repair Procedure”.

(See 01-02-10 AFTER REPAIR

PROCEDURE[L3 WITH TC].)

• Are any DTCs present?

Yes

Go to the applicable DTC inspection.

(See 01-02-13 DTC TABLE[L3 WITH TC].)

No

Troubleshooting completed.

STEP

INSPECTION

ACTION

DTC P0012

CMP Timing over-retarded

DETECTION

CONDITION

• Actual valve timing is over-retarded by 5 ° (when the following conditions are met) from the target

valve timing for 5 s when the OCV system control is within the feed-back range.

MONITORING CONDITION

— Engine speed is below 4,000 rpm.

— Engine coolant temperature is above 70— 110

°C {158— 230 °F}.

Diagnostic support note

• This is a continuous monitor (CCM).

• MIL illuminates if the PCM detects the above malfunction condition in two consecutive drive cycles or in

one drive cycle while the DTC for the same malfunction has been stored in the PCM.

• PENDING CODE is available if the PCM detects the above malfunction condition during the first drive

cycle.

• FREEZE FRAME DATA is available.

• DTCs are stored in the PCM memory.

POSSIBLE

CAUSE

• OCV malfunction

• Low engine oil pressure

• Spool valve in OCV is stuck in the retard position.

• Variable valve timing actuator is stuck in the retard position.

• Following oil runners are clogged or have leakage.

Oil runners

• Between oil pressure switch and OCV

• Between OCV and variable valve timing actuator

• In variable valve timing actuator

• Loose timing chain or improper valve timing due to timing chain slippage

• PCM malfunction

STEP

INSPECTION

ACTION

1

VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

• Has the FREEZE FRAME DATA been

recorded?

Yes

Go to the next step.

No

Record FREEZE FRAME DATA on the repair order, then go

to the next step.

2

VERIFY RELATED REPAIR INFORMATION

AVAILABILITY

• Check for related Service Bulletins and/or on-

line repair information availability.

• Is any related repair information available?

Yes

Perform the repair or diagnosis according to the available

repair information.

• If the vehicle is not repaired, go to the next step.

No

Go to the next step.

3

VERIFY RELATED PENDING CODE OR

STORED DTCS

• Is DTC P2088 or P2089 present?

Yes

Go to the appropriate DTC troubleshooting procedure.

(See 01-02-188 DTC P2088[L3 WITH TC] or 01-02-190

DTC P2089[L3 WITH TC].)

No

Go to the next step.

4

VERIFY ENGINE OIL PRESSURE

• Start the engine.

• Does the oil pressure warning light illuminate?

Yes

Inspect engine oil pressure.

(See 01-11-2 OIL PRESSURE INSPECTION[L3 WITH

TC].)

No

Go to the next step.

1871-1U-06B(01-02).fm 23 ページ 2006年3月15日 水曜日 午前10時32分