Mazda Protege 5. Manual - part 222

ON-BOARD DIAGNOSTIC

05–02–16

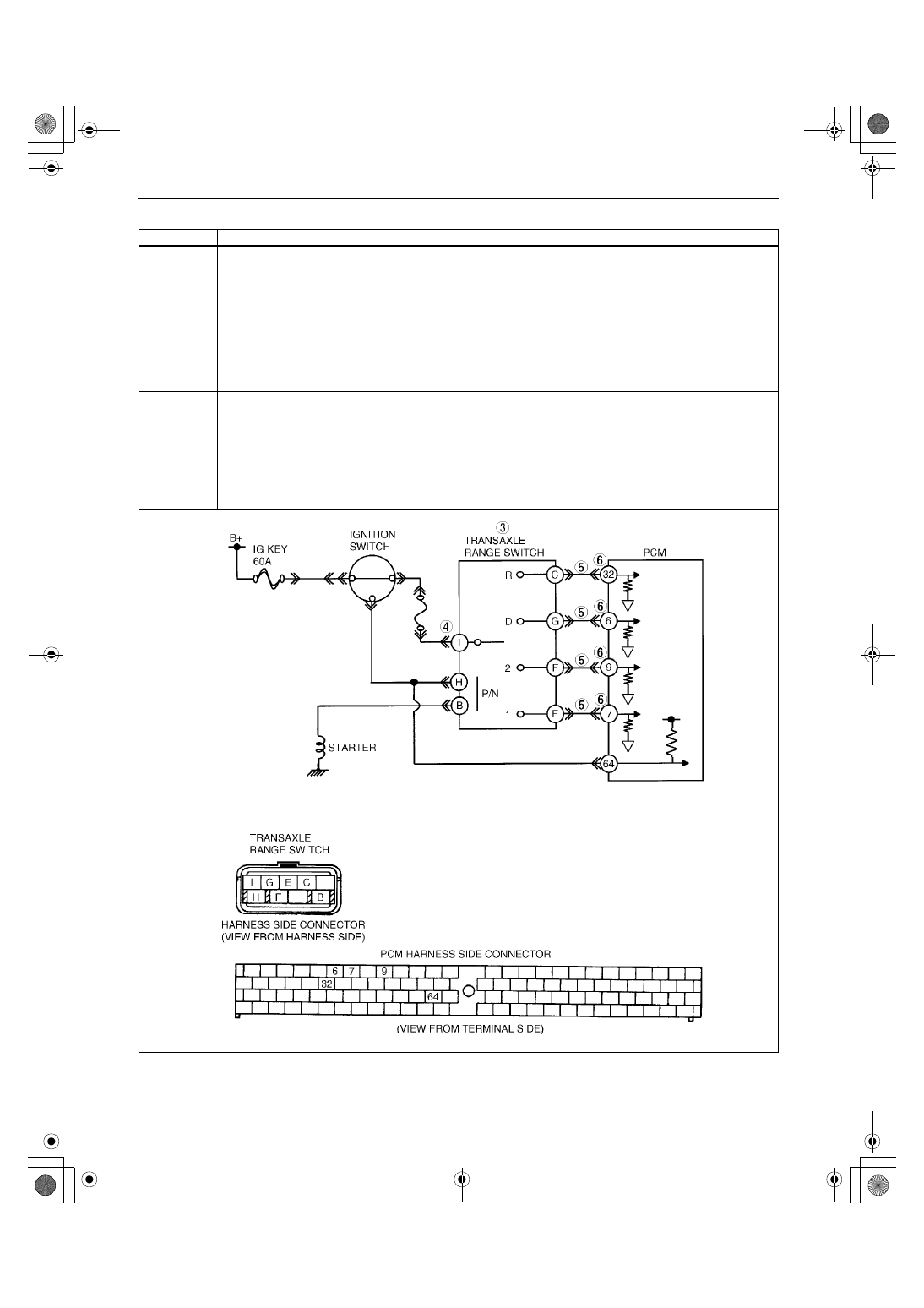

DTC P0706

A3U050201030W08

DTC P0706

Transaxle range (TR) switch circuit malfunction (open circuit)

DETECTION

CONDITION

•

When all conditions below satisfied and 100 seconds or more have passed.

— D, 2, 1range and R range switch not input.

— Engine speed 530 rpm or above.

— Vehicle speed 20 km/h {12 mph} or above.

Diagnostic support note:

•

This is a continuous monitor (CCM).

•

MIL illuminates if PCM detects the above malfunction conditions during two consecutive drive cycles.

•

PENDING CODE is available.

•

FREEZE FRAME DATA is available.

•

O/D OFF indicator light flashes.

•

DTC is stored in the PCM memory.

POSSIBLE

CAUSE

•

Charging system malfunction

•

TR switch malfunction

•

TR switch misadjustment

•

Open circuit between TR switch terminal G and PCM terminal 6

•

Open circuit between TR switch terminal F and PCM terminal 9

•

Open circuit between TR switch terminal E and PCM terminal 7

•

Open circuit between TR switch terminal I and dash harness (JB-04) terminals

•

Damaged connectors between TR switch and PCM

•

PCM malfunction

1712-1U-01G(05-02).fm 16 ページ 2001年6月29日 金曜日 午後4時35分