Mazda Protege 5. Manual - part 101

SYMPTOM TROUBLESHOOTING [ENGINE CONTROL SYSTEM (ZM)]

01–03A–57

01–03A

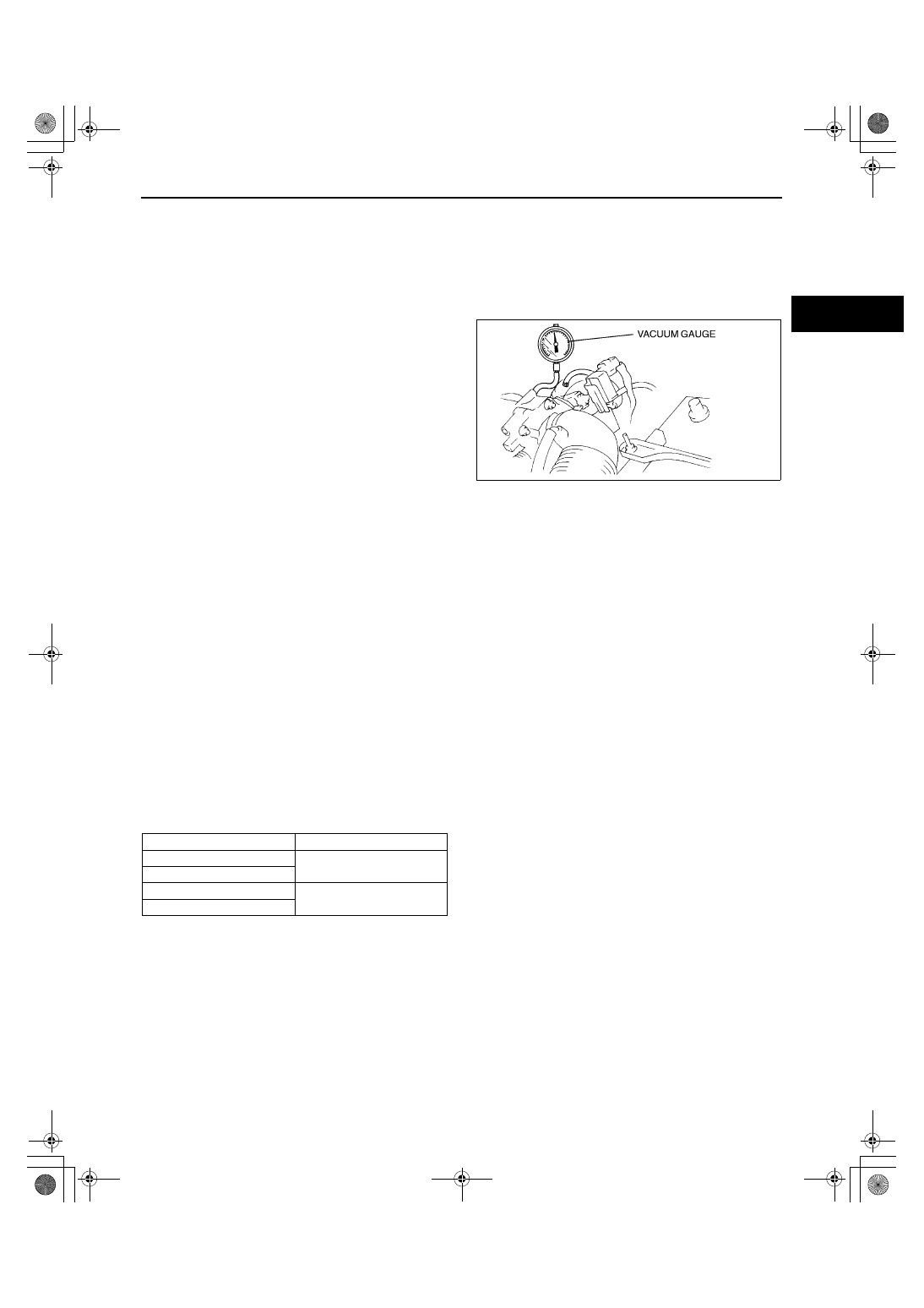

Intake Manifold Vacuum Inspection

1. Verify air intake hoses are installed properly.

2. Start the engine and run it at idle.

3. Measure the intake manifold vacuum using a vacuum gauge.

•

If not as specified, inspect the following:

— Air suction at throttle body, intake manifold and PCV valve installation points

— Fuel injector insulator

— Accelerator cable free play

— Engine compression (See 01–10A–8

COMPRESSION INSPECTION [ZM].)

Specification

More than 60 kPa {450 mmHg, 18 inHg}

Note

•

Air suction can be located by engine speed

change when lubricant is sprayed on the

area where suction is occurring.

Idle Air Control (IAC) Inspection

Engine coolant temperature compensation inspection

1. Connect the WDS or equivalent to DLC-2.

2. Select the following PIDs.

•

ECT

•

RPM

3. Verify that the engine is in cold condition, then start the engine.

4. Verify that the engine speed decreases as the engine warms up.

•

If the engine speed does not decrease or decreases slowly, carry out the following:

— ECT sensor inspection

— IAC valve inspection

Load compensation inspection

1. Warm up the engine to normal operating temperature and run it at idle.

2. Connect the WDS or equivalent to DLC-2.

3. Select the following PID.

•

RPM

4. Turn the electrical loads on and verify that the engine speed is within the specification.

•

If not as specified, carry out the following:

— A/C switch inspection

— P/S pressure switch inspection

— IAC valve inspection

Engine speed (rpm)

*

: Neutral or P position

Note

•

Excludes temporary idle speed drop just after the loads are turned on.

X3U101WCW

Load condition

Idle-up speed (rpm)*

No load

650—750 (700

±

50)

Headlight switch is on.

P/S on

700—800 (750

±

50)

A/C on

1712-1U-01G(01-03A).fm 57 ページ 2001年6月29日 金曜日 午後4時45分