Lifan 620. Manual - part 50

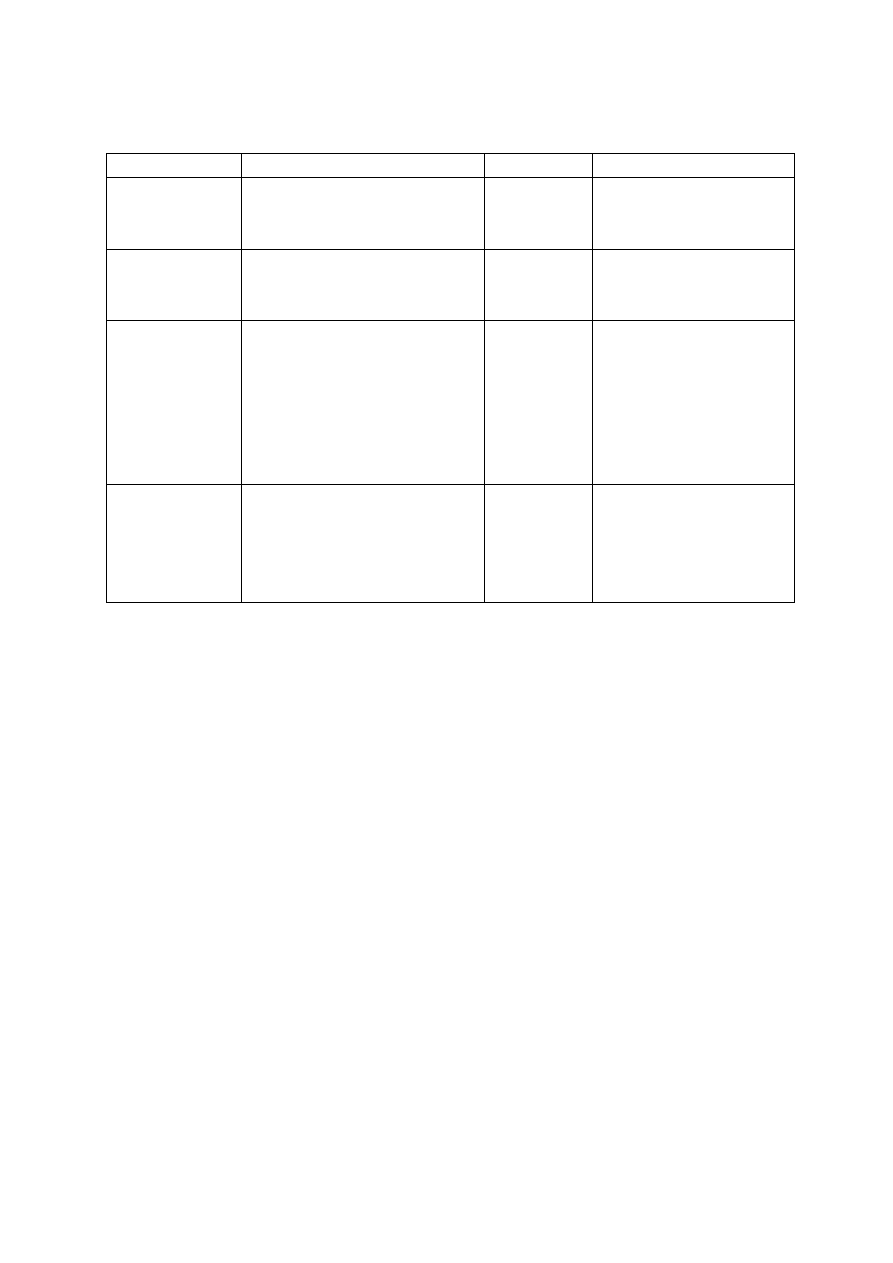

IV. Trouble Symptom

Table 4-3

Table 4-3

Symptom Cause

Symptom Cause

1

Instrument cluster

does not work

1 Faulty fuse

2 Faulty wiring and connector

3 Faulty instrument cluster

2

Speedometer

fault

1 Faulty speed sensor

2 Faulty wiring and connector

3 Faulty instrument cluster

3

Tachometer fault

1 Faulty engine or ECM

2 Faulty wiring and connector

3 Faulty instrument cluster

4 Fuel gauge

fault

1 Faulty fuel level sensor

2 Faulty wiring and connector

3 Faulty instrument cluster

5

fault

7

①

Check

②

the resistance between connector terminal A9 and the body, normally less than 1Ω. If it

is in a normal condition, replace the instrument cluster, if not, repair or change the wire and

connector.

(2) Check the circuit as shown in Fig. 4-20.

2. Speedometer fault

(1) Check steps

1) Check the power input end of speed sensor.

Ignition switch ON-position, check the voltage between 1-T2 and the body, normally around 10~

14V.

201