Isuzu Trooper (1998-2002 year). Manual - part 569

6A – 84 ENGINE MECHANICAL

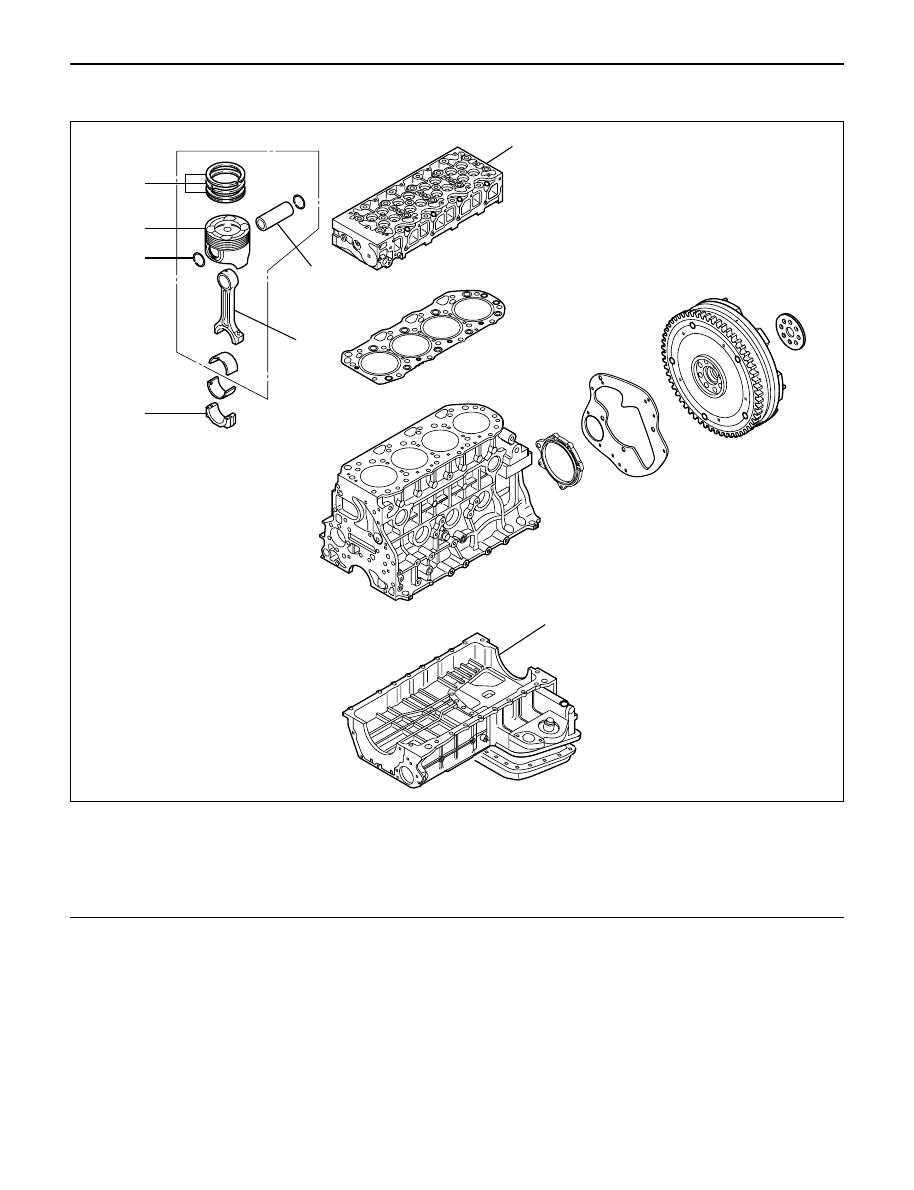

PISTON AND CONNECTING ROD

5

8

7

3

1

2

6

4

012RW061

Legend

(1)

Cylinder Head Assembly

(2)

Crank Case

(3)

Connecting Rod Bearing Cap

(4)

Connecting Rod

(5)

Piston Ring

(6)

Piston Pin

(7)

Piston Pin Snap Ring

(8)

Piston