Isuzu Trooper (1998-2002 year). Manual - part 567

6A – 76 ENGINE MECHANICAL

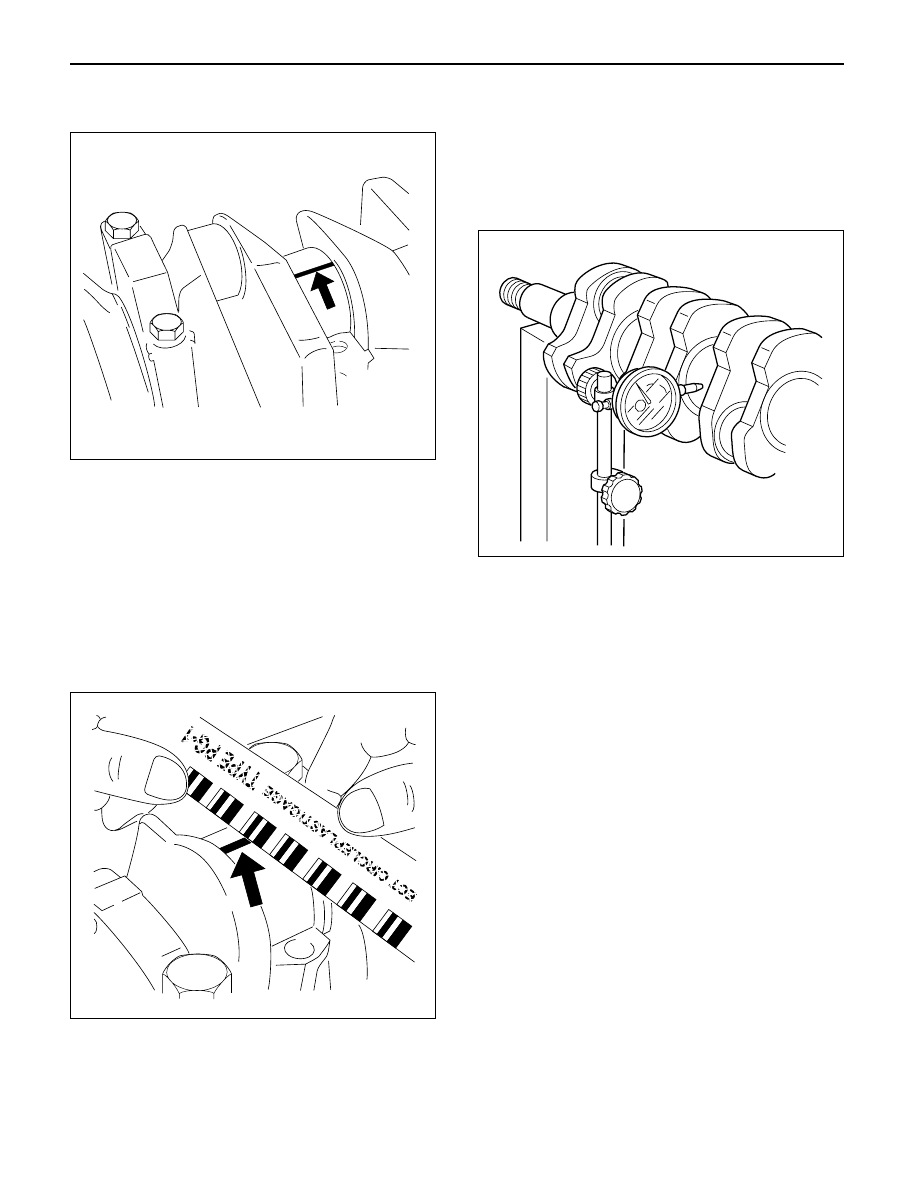

7) Apply plastigage to the crankshaft journal unit as

shown in the illustration.

8) Install the main bearing caps. Apply engine oil to

the bolt threads and the seats. Tighten the bolts

to the specified torque.

Torque: 167 N·m (17 kg·m/123 lb ft)

NOTE: Do not allow the crankshaft to rotate.

9) Remove the main bearing caps.

10) Measure the plastigage width and determine the

oil clearance. If the oil clearance exceeds the

specified limit, replace the main bearings as a

set and/or replace the crankshaft.

11) Clean the plastigage from the bearings and the

crankshaft.

Remove the crankshaft and the bearings.

Standard: 0.031 – 0.063 mm (0.0012 – 0.0025 in)

Limit: 0.11 mm (0.0043 in)

3. Run-out

1) Carefully set the crankshaft on the V-blocks.

Slowly rotate the crankshaft and measure the

runout. If the crankshaft runout exceeds the

specified limit, the crankshaft must be replaced.

Standard: 0.05 mm (0.0020 in) or less

Limit: 0.08 mm (0.0031 in)

Measure the diameter and the uneven wear of

main journal and crank pin.

If the crankshaft wear exceeds the specified

limit, crankshaft must be replaced.

Main journal diameter

Standard: 69.917 – 69.932 mm (2.7526 – 2.7532 in)

Limit: 69.91 mm (2.7524 in)

Crank pin diameter

Standard: 52.915 – 52.930 mm (2.0833 – 2.0839 in)

Limit: 52.90 mm (2.0827 in)

Uneven wear limit

Standard: 0.05 mm (0.0020 in) or less

Limit: 0.08 mm (0.0031 in)

014RW055

014RW077

012RW068