Isuzu Trooper (1998-2002 year). Manual - part 566

6A – 72 ENGINE MECHANICAL

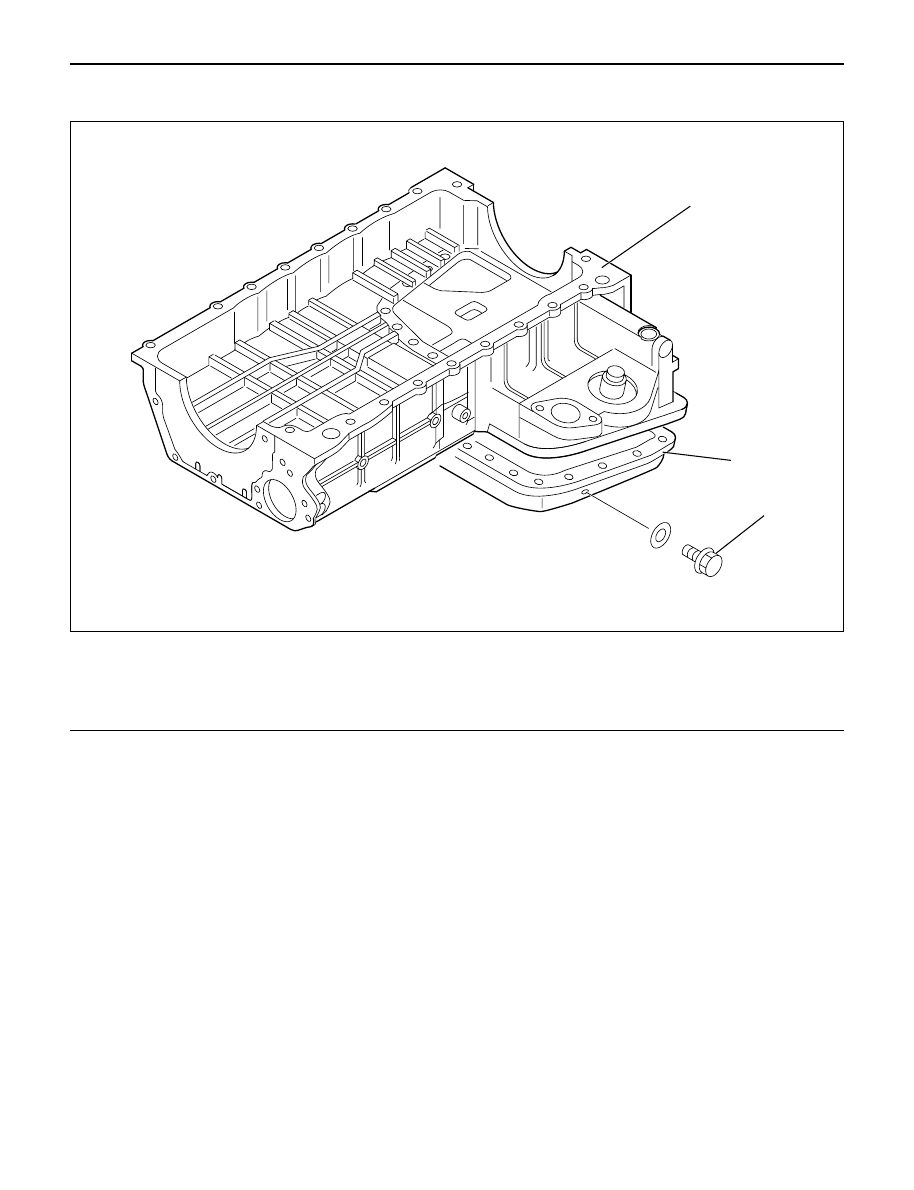

CRANK CASE

REMOVAL

1. Drain engine oil.

2. Remove transmission assembly.

3. Remove crankshaft damper pulley.

4. Remove timing belt cover, timing belt, pulley and

front plate.

5. Remove timing gear case cover.

6. Remove timing gears.

NOTE: Do not forget to set lock bolt for idle gear A and

lock pin for idle gear C.

7. Remove timing gear case.

8. Remove oil level gauge guide assembly.

9. Remove flywheel assembly.

CAUTION:

1) The flywheel heavy; be careful not to drop it.

2) Be careful no to let it slip because the hexagon

of the bolt is thin.

10. Remove rear plate (for A/T) or flywheel housing (for

MT).

11. Remove retainer.

NOTE:

1) Be careful not to damage the oil seal; it can be

reused.

2) Inspect installation portion for distortion and flow on

the slinger; also inspect for flow on the oil seal lip.

3) If there is some flow oil seal/slinger, replace a set.

12. Remove bolts from thrust plate of balance shaft LH

then remove balance shaft.

13. Loosen crank case fixing bolts.

14. Use seal cutter to take off the liquid gasket.

Seal cutter: 5-8840-2153-0

15. Remove crank case assembly.

CAUTION:

Do not give shock to crank case for prevention take

off applied vibration insulation material on the

crank case.

1

2

3

012RW029

Legend

(1)

Crank Case

(2)

Oil Pan

(3)

Drain Plug