Isuzu Trooper (1998-2002 year). Manual - part 570

6A – 88 ENGINE MECHANICAL

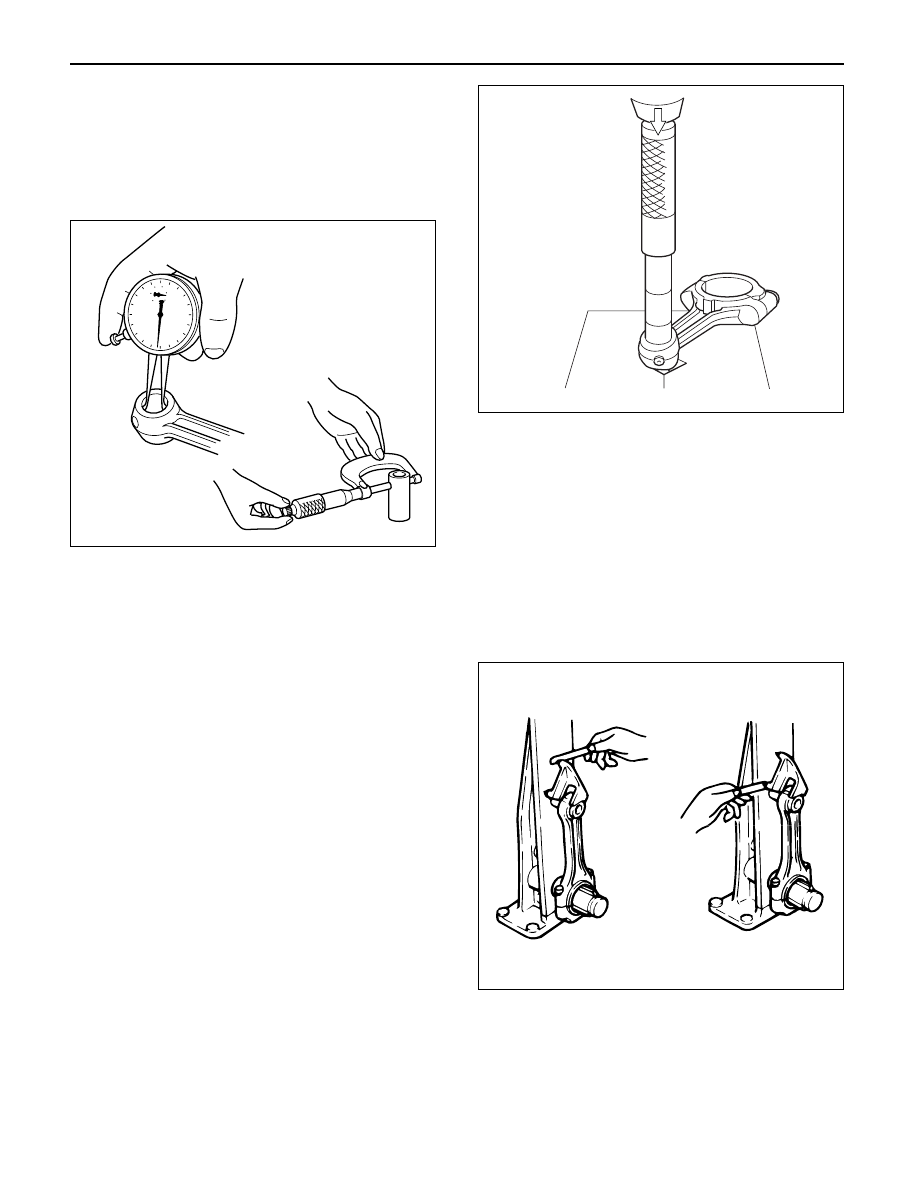

2. Measure the inside diameter of the connecting rod

small end. If the clearance between the small end

and pin does not conform to the specified value, the

connecting rod or bushing and pin must be

replaced.

Standard: 0.008 – 0.020 mm (0.0003 – 0.0008 in )

Limit: 0.05 mm (0.0020 in)

3. Insert the piston pin into the piston and rotate it. If

the pin rotates smoothly with no backlash, the

clearance is normal. If there is backlash or

roughness, measure the clearance. If the clearance

exceeds the specified limit, the piston and the

piston pin must be replaced.

Standard: 0.005 – 0.018 mm (0.0002 – 0.0007 in )

Limit: 0.04 mm (0.0016 in)

Bushing replacement

Removal:

Use a suitable bar and bench press or

hammer

Installation:

Align the bushing with a connecting rod

oil port. After installing a new bushing,

finish the bushing bore with a pin hole

grinder.

Connecting rods

1. Check the connecting rod alignment with a

connecting rod aligner.

If either the bend or the twist exceeds the specified

limit, the connecting rod must be replaced.

Bend per 100 mm (3.937 in)

Standard: 0.08 mm (0.0031 in) or less

Limit: 0.20 mm (0.0079 in)

Twist per 100 mm (3.937 in)

Standard: 0.05 mm (0.0020 in) or less

Limit: 0.15 mm (0.0059 in)

2. Measure the connecting rod thrust clearance.

Use a feeler gauge to measure the thrust clearance

at the big end of the connecting rod.

If the clearance exceeds the specified limit, the

connecting rod must be replaced.

Standard: 0.230 mm (0.0091 in)

Limit: 0.350 mm (0.0138 in)

012RW074

012RW123

012RW001