Isuzu Trooper (1998-2002 year). Manual - part 532

6E–498

6VE1 3.5 ENGINE DRIVEABILITY AND EMISSIONS

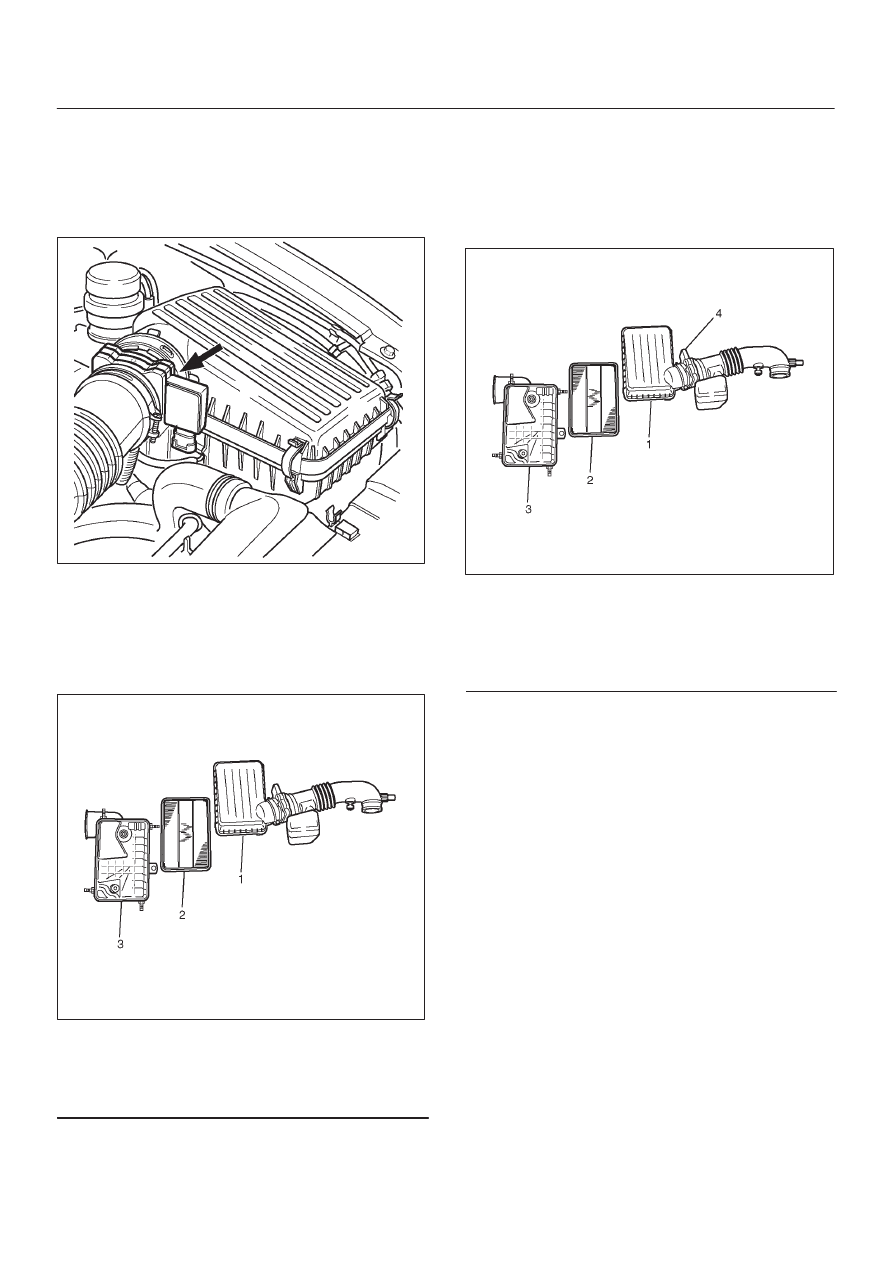

Air Cleaner/Air Filter

Removal Procedure

1. Loosen the clamp between the air cleaner lid and the

mass air flow sensor.

060R200240

2. Release the four latches securing the lid to the air

cleaner housing.

3. Remove the air cleaner lid.

4. Remove the air filter element.

5. Remove the retaining bolts and the air cleaner

housing from the vehicle.

060R200220

Legend

(1) Air Cleaner Lid

(2) Air Filter Element

(3) Air Cleaner Housing

Installation Procedure

1. Install the air cleaner housing in the vehicle with the

retaining bolts.

2. Install the air filter element in the air cleaner housing.

3. Install the air cleaner lid on the MAF sensor and the air

cleaner housing.

060R200241

Legend

(1) Air Cleaner Lid

(2) Air Filter Element

(3) Air Cleaner Housing

(4) Mass Air Flow Sensor

4. Tighten the clamp and secure the four latches

between the lid and the air cleaner housing.

Common Chamber

Removal and Installation Procedure

Refer to Common Chamber in Engine Mechanical

section.