Isuzu Trooper (1998-2002 year). Manual - part 531

6E–494

6VE1 3.5 ENGINE DRIVEABILITY AND EMISSIONS

Malfunction Indicator Lamp

(MIL)

Removal and Installation Procedure

Refer to Warning light bulb, indicator light valve,

illumination light bulb, A/T indicator light bulb in Meter and

Gauge.

Reduced Power Lamp

The reduced power lamp (RPL) turns on when the ignition

key is moved to the ON position. It should turn off in

approximately 3 seconds or immediately after the engine

starts.

If the RPL turns on during vehicle operation, a vehicle

system failure resulting in reduced engine output is

indicated.

If both the reduced RPL and the check engine light turn

on, a serious problem affecting vehicle performance is

indicated.

Refer to the

OBD system check NO and RPL “ON” steady

in this manual.

Powertrain Control Module

(PCM)

Service Precaution

NOTE: To prevent possible electrostatic discharge

damage to the PCM, do not touch the connector pins or

soldered components on the circuit board.

Electrostatic Discharge (ESD)

Damage

Electronic components used in the control systems are

often designed to carry very low voltage. Electronic

components are susceptible to damage caused by

electrostatic discharge. Less than 100 volts of static

electricity can cause damage to some electronic

components. By comparison, it takes as much as 4,000

volts for a person to even feel the zap of a static

discharge.

There are several ways for a person to become statically

charged. The most common methods of charging are by

friction and by induction. An example of charging by

friction is a person sliding across a car seat.

Charging by induction occurs when a person with well

insulated shoes stands near a highly charged object and

momentarily touches ground. Charges of the same

polarity are drained off leaving the person highly charged

with the opposite polarity. Static charges can cause

damage, therefore, it is important to use care when

handling and testing electronic components.

NOTE: To prevent possible Electrostatic Discharge

damage, follow these guidelines:

D

Do not touch the control module connector pins or

soldered components on the control module circuit

board.

D

Do not open the replacement part package until the

part is ready to be installed.

D

Before removing the part from the package, ground

the package to a known good ground on the vehicle.

D

If the part has been handled while sliding across the

seat, or while sitting down from a standing position, or

while walking a distance, touch a known good ground

before installing the part.

NOTE: To prevent internal PCM damage, the ignition

must be in the “OFF” position in order to disconnect or

reconnect power to the PCM (for example: battery cable,

PCM pigtail, PCM fuse, jumper cables, etc.).

IMPORTANT:

When replacing the production PCM

with a service PCM, it is important to transfer the

broadcast code and production PCM number to the

service PCM label. This will allow positive identification of

PCM parts throughout the service life of the vehicle. Do

not record this information on the metal PCM cover.

IMPORTANT:

The ignition should always be in the

“OFF” position in order to install or remove the PCM

connectors.

Service of the PCM should normally consist of either re-

placement of the PCM or EEPROM programming. If the

diagnostic procedures call for the PCM to be replaced,

the PCM should be checked first to ensure it is the correct

part. If it is, remove the faulty PCM and install the new

service PCM.

The service PCM EEPROM will not be programmed.

DTC P0601 indicates the check sum error.

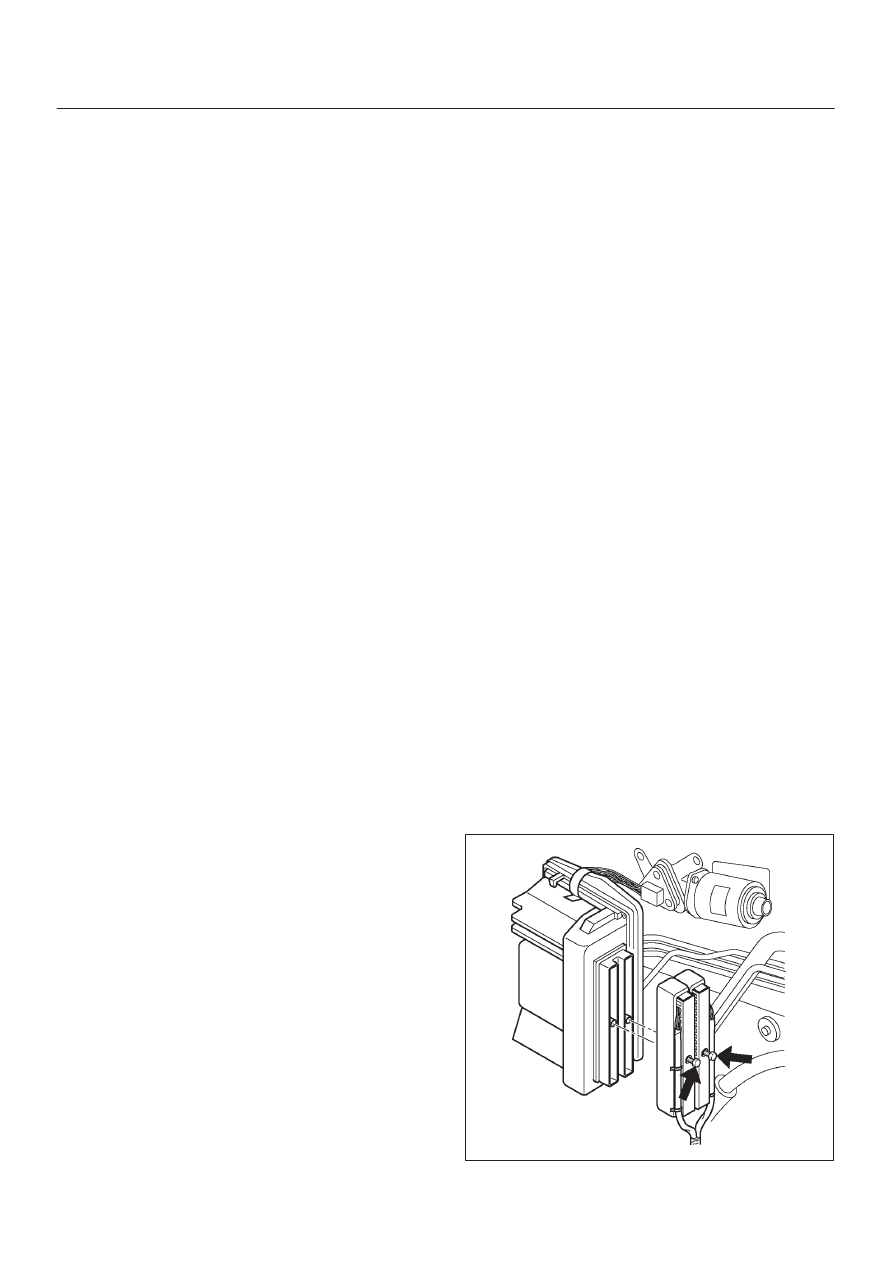

Removal Procedure

1. Disconnect the negative battery cable.

2. Block the wheels.

3. Remove the two screws from the PCM electrical

connectors.

4. Disconnect the PCM electrical connectors.

060RY00031