Isuzu Trooper (1998-2002 year). Manual - part 494

6E–346

6VE1 3.5 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC)

P1115 ECT Sensor Circuit Intermittent High Voltage

D06R200049

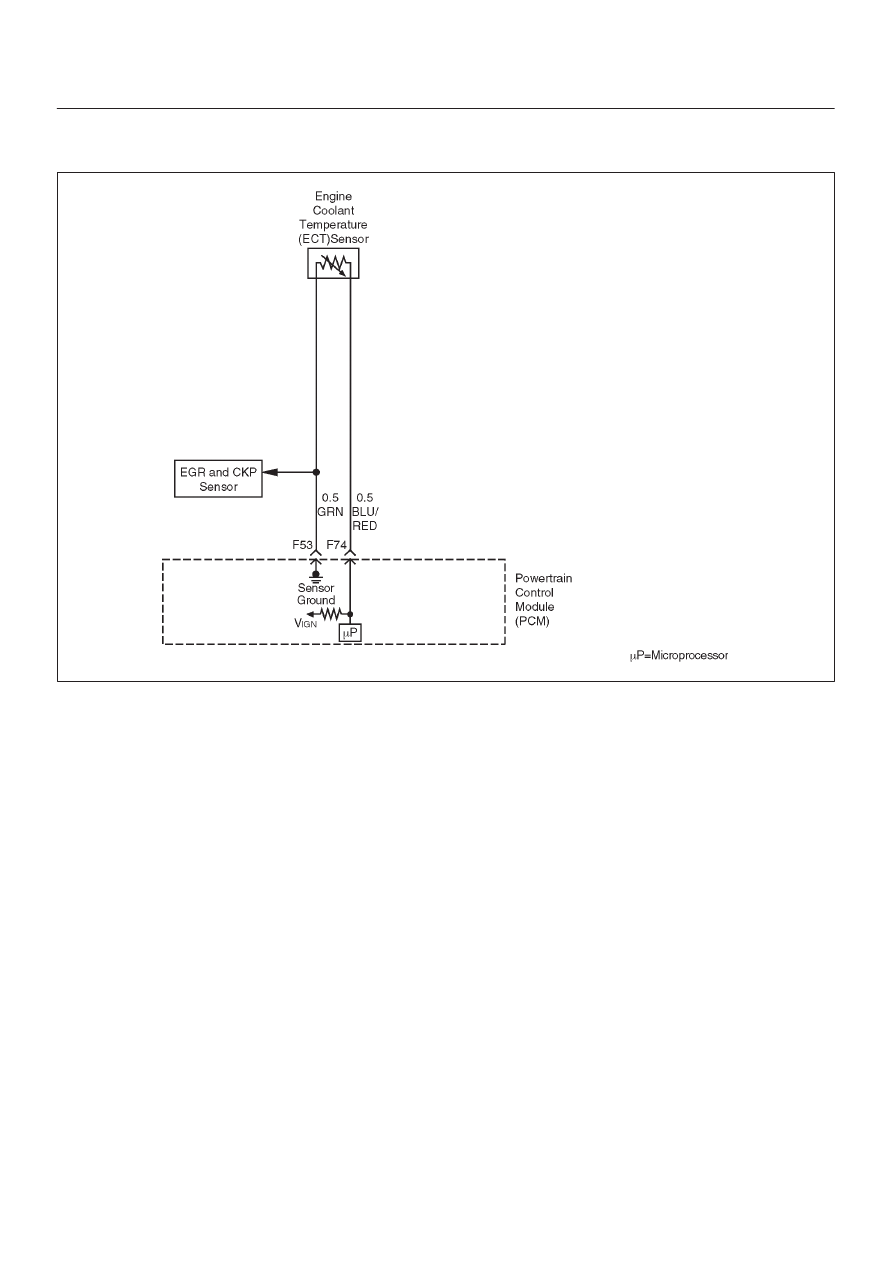

Circuit Description

The engine coolant temperature (ECT) sensor is a

thermistor mounted in the engine coolant stream. The

powertrain control module (PCM) applies a voltage

(about 5.0 volts) through a pull-up resistor to the ECT

signal circuit. When the engine coolant is cold, the sensor

(thermistor) resistance is high, therefore the PCM will

measure a high signal voltage. As the engine coolant

warms, the sensor resistance becomes less, and the

ECT signal voltage measured at the PCM drops. With a

fully warmed up engine, the ECT signal voltage should

measure about 1.5 to 2.0 volts. If the PCM detects an

ECT signal that is intermittently above the range of the

ECT sensor, DTC P1115 will set.

Conditions for Setting the DTC

D

Engine running time longer than 90 seconds.

D

The ECT sensor signal is intermittently greater than

–39

°

C (–38

°

F) (about 5 volts) for a total of 10 seconds

over a 100-second period.

Action Taken When the DTC Sets

D

The PCM will not illuminate the malfunction indicator

lamp (MIL).

D

The PCM will store conditions which were present

when the DTC was set as Failure Records data only.

This information will not be stored as Freeze Frame

data.

Conditions for Clearing the MIL/DTC

D

A history DTC P1115 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

D

DTC P1115 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

D

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

D

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the ECT sensor. A

change in the ECT display will indicate the location of

the fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often