Isuzu Trooper (1998-2002 year). Manual - part 437

6E–118

6VE1 3.5 ENGINE DRIVEABILITY AND EMISSIONS

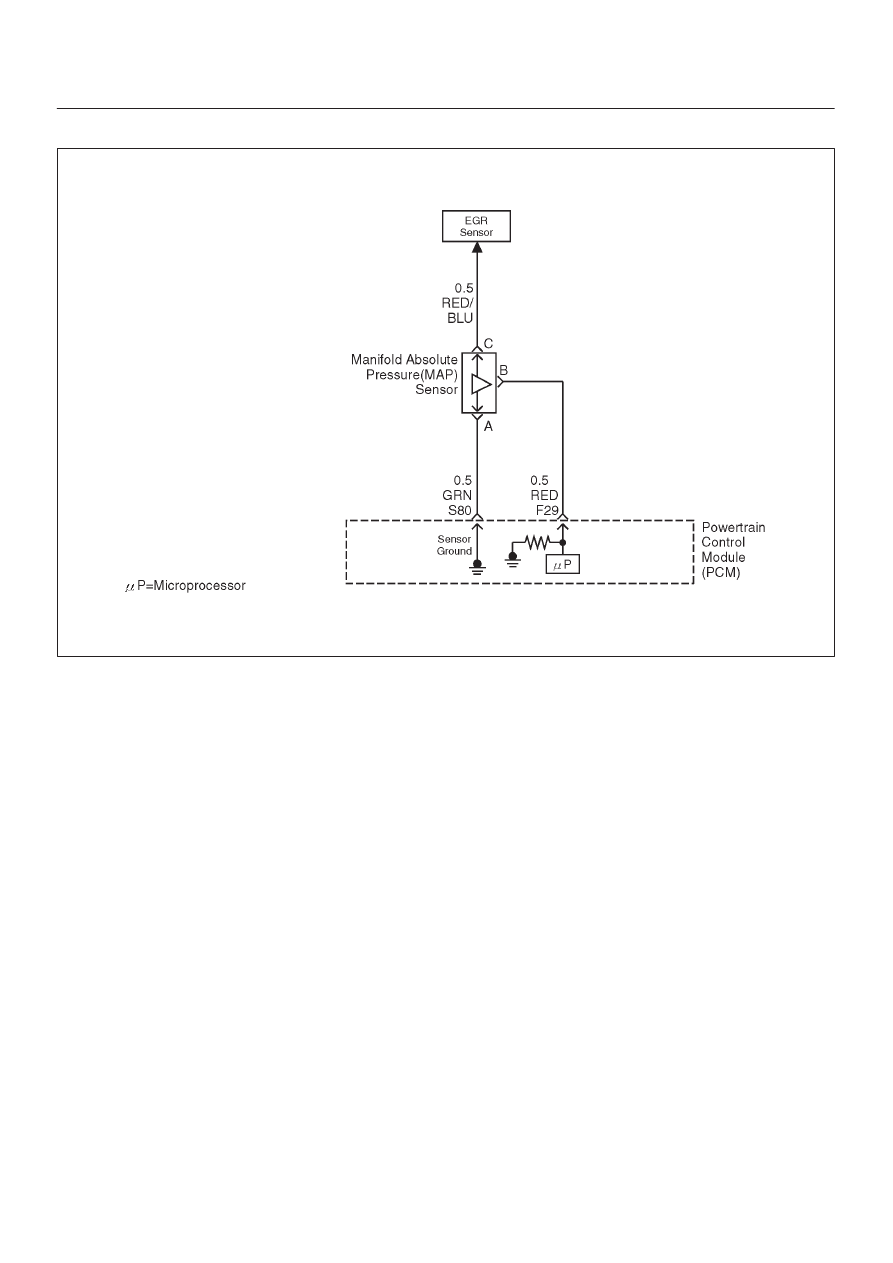

Manifold Absolute Pressure (MAP) Output Check

D06R200048

Circuit Description

The manifold absolute pressure (MAP) sensor measures

the changes in the intake MAP which result from engine

load (intake manifold vacuum) and engine speed

changes; and converts these into a voltage output. The

powertrain control module (PCM) sends a 5-volt

reference voltage to the MAP sensor. As the MAP

changes, the output voltage of the sensor also changes.

By monitoring the sensor output voltage, the PCM knows

the MAP. A lower pressure (low voltage) output voltage

will be about 1-2 volts at idle. Higher pressure (high

voltage) output voltage will be about 4-4.8 volts at wide

open throttle. The MAP sensor is also used, under certain

conditions, to measure barometric pressure, allowing the

PCM to make adjustments for different altitudes. The

PCM uses the MAP sensor to diagnose proper operation

of the EGR system, in addition to other functions.

Test Description

IMPORTANT:

Be sure to used the same diagnostic test

equipment for all measurements.

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Applying 34 kPa (10 inch Hg) vacuum to the MAP

sensor should cause the voltage to be 1.5-2.1 volts

less than the voltage at step 1. Upon applying

vacuum to the sensor, the change in voltage should

be instantaneous. A slow voltage change indicates

a faulty sensor.

3. Check the vacuum hose to the sensor for leaking or

restriction, Be sure that no other vacuum devices

are connected to the MAP hose.

IMPORTANT:

Make sure the electrical connector

remains securely fastened.

4. Disconnect the sensor from the bracket. Twist the

sensor with your hand to check for an intermittent

connection. Output changes greater than 0.10 volt

indicate a bad sensor.