Isuzu Trooper (1998-2002 year). Manual - part 436

6E–114

6VE1 3.5 ENGINE DRIVEABILITY AND EMISSIONS

Fuel System Diagnosis

(Cont'd)

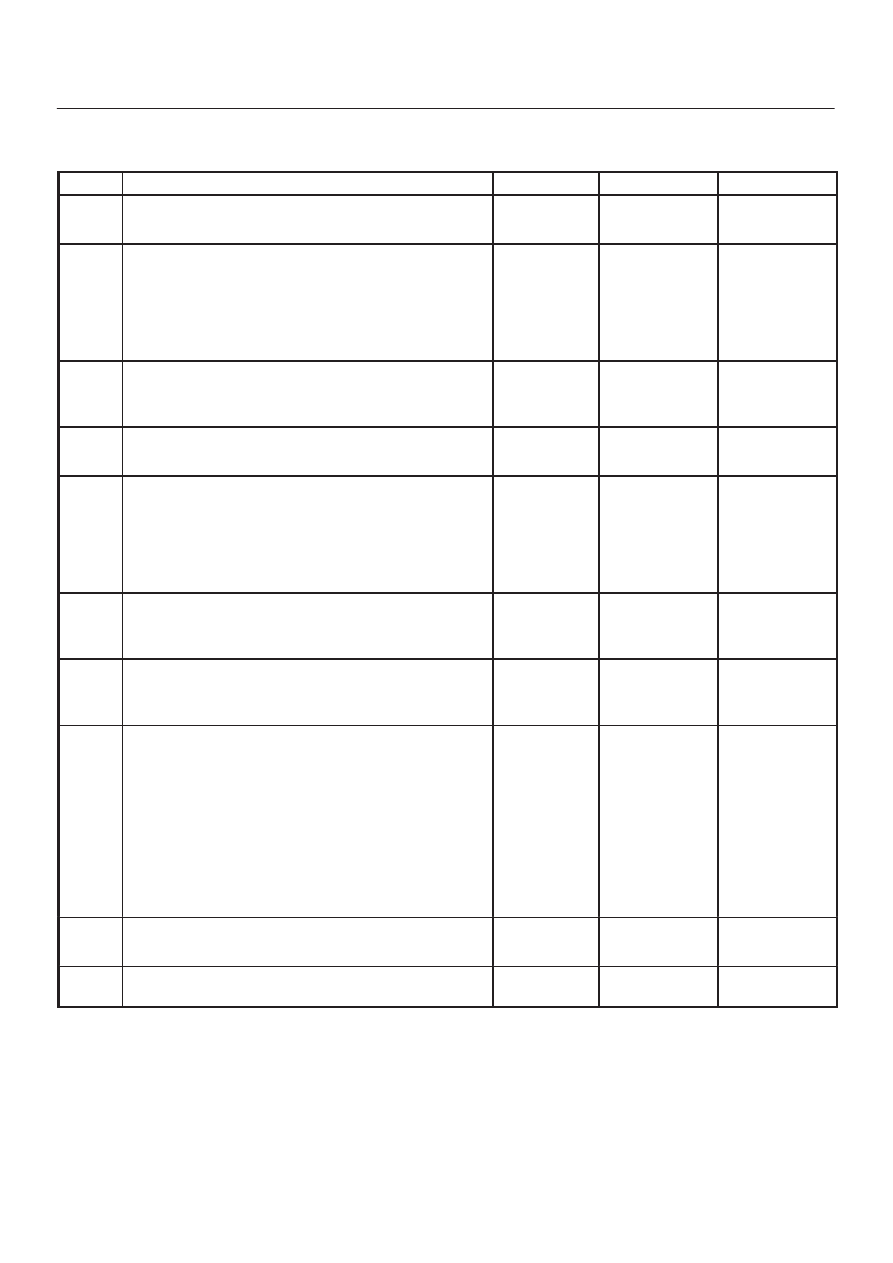

Step

No

Yes

Value(s)

Action

8

Replace the fuel pump.

Is the action complete?

—

Verify repair

—

9

1. Disconnect the vacuum hose from the fuel pressure

regulator.

2. With the engine idling, apply 12-14 inches of

vacuum to the fuel pressure regulator.

Does the fuel pressure indicated by the fuel pressure

gauge drop by the amount specified?

21-105 kPa

(3-15 psi)

Go to

Step 10

Go to

Step 11

10

Locate and repair the loss of vacuum to the fuel

pressure regulator.

Is the action complete?

—

Verify repair

—

11

Replace the fuel pressure regulator.

Is the action complete?

—

Verify repair

—

12

1. Run the fuel pump with the Tech 2.

2. After pressure has built up, turn off the pump and

clamp the supply hose shut with suitable locking

pliers which will not damage the hose.

Does the fuel pressure indicated by the fuel pressure

gauge remain constant?

—

Go to

Step 13

Go to

Step 15

13

Visually inspect the fuel supply line and repair any

leaks.

Was a problem found?

—

Verify repair

Go to

Step 14

14

Remove the fuel tank and inspect for leaky hose or

in-tank fuel line.

Was a problem found?

—

Verify repair

Go to

Step 8

15

1. If the pliers are still clamped to the fuel supply hose,

remove the locking pliers.

2. With suitable locking pliers, which will not damage

the hose, clamp the fuel return line to prevent fuel

from returning to the fuel tank.

3. Run the fuel pump with the Tech 2.

4. After pressure has built up, remove power to the

pump.

Does the fuel pressure indicated by the fuel pressure

gauge remain constant?

—

Go to

Step 11

Go to

Step 16

16

Locate and replace any leaking fuel injector(s).

Is the action complete?

—

Verify repair

—

17

Is the fuel pressure indicated by the fuel pressure

gauge above the specified limit?

376 kPa

(55 psi)

Go to

Step 18

Go to

Step 21