Content .. 1090 1091 1092 1093 ..

Isuzu Trooper (1998-2002 year). Manual - part 1092

9J1–5

RESTRAINT CONTROL SYSTEM

diagnostic trouble codes in the order specified may result

in extended diagnostic time, incorrect diagnosis and

incorrect parts replacement.

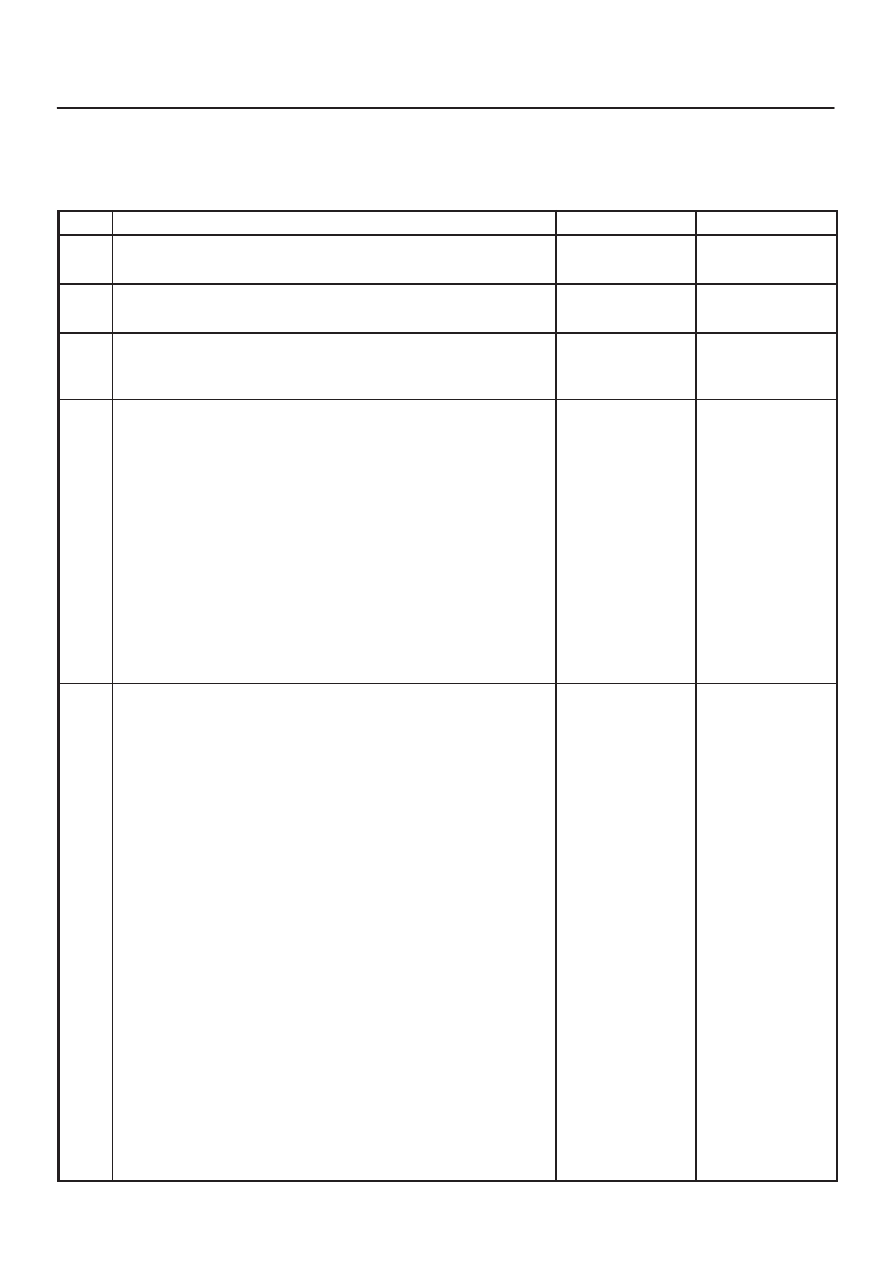

SRS Diagnostic System Check

Step

Action

Yes

No

1

Note the “Air Bag” warning lamp as ignition switch is turned “ON.”

Does the “AIR BAG” warning lamp turn on 3.5 seconds?

Go to Step 2

Go to Step 3

2

Note the “AIR BAG” warning lamp after it turn on 3.5 seconds.

Does the “AIR BAG” warning lamp go “OFF”?

Go to Step 4

Go to Step 5

3

Note the “AIR BAG” warning lamp as ignition switch is turned

“ON”.

Does the “AIR BAG” warning lamp come “ON” steady?

Go to Chart B

Go to Chart C

4

1. Note the “AIR BAG” warning lamp as that ignition switch is

turned “ON.”

Ignition switch “OFF.”

2. Connect a scan tool to data link connector.

3. Follow direction given in the scan tool instruction manual.

Ignition switch “ON.”

4. Request the SRS diagnostic trouble code display, recode all

history diagnostic trouble code(s). specify as such, on repair

order

Is (are) diagnostic trouble code(s) displayed?

Ignition switch

“OFF”

When DTC 71 is

set, go to DTC 71

Chart

For all other

history codes

refer to

“Diagnostic Aids”

For that specific

DTC

A history DTC

indicates the

malfunction has

been repaired or

is intermittent

SRS is functional

and free of

malfuncitons, no

further diagnosis

is required

If scan tool

indicated “NO

DATA

RECEIVED,”

refer to chassis

electrical section8

5

1. Ignition switch “OFF.”

2. Connect a scan tool to data link connector.

3. Follow directions as given in the scan tool instruction manual.

4. Ignition switch “ON.”

5. Request the SRS diagnostic trouble code display, Recode all

diagnostic trouble code(s), specifying as current or history on

repair order.

Is (are) diagnostic trouble code (s) displayed?

Ignition switch

“OFF”

When DTC 53 is

set, go to DTC 53

chart

When DTC 51 is

set, go to DTC 51

chart

When DTC 19 is

set, go to DTC 19

chart

When DTC 25 is

set, go to DTC 25

chart

Diagnose

remaining current

DTCs from

lowest to highest

When only history

DTCs exist, refer

to “Diagnostics

Aids” for that

specific DTC

A history DTC

indicates the

malfunction has

been repaired or

is intermittent

If scan tool

indicates “No

Data Received,”

refer to chassis

electrical section8