Infiniti QX56 (JA60). Manual - part 471

EM-38

< ON-VEHICLE REPAIR >

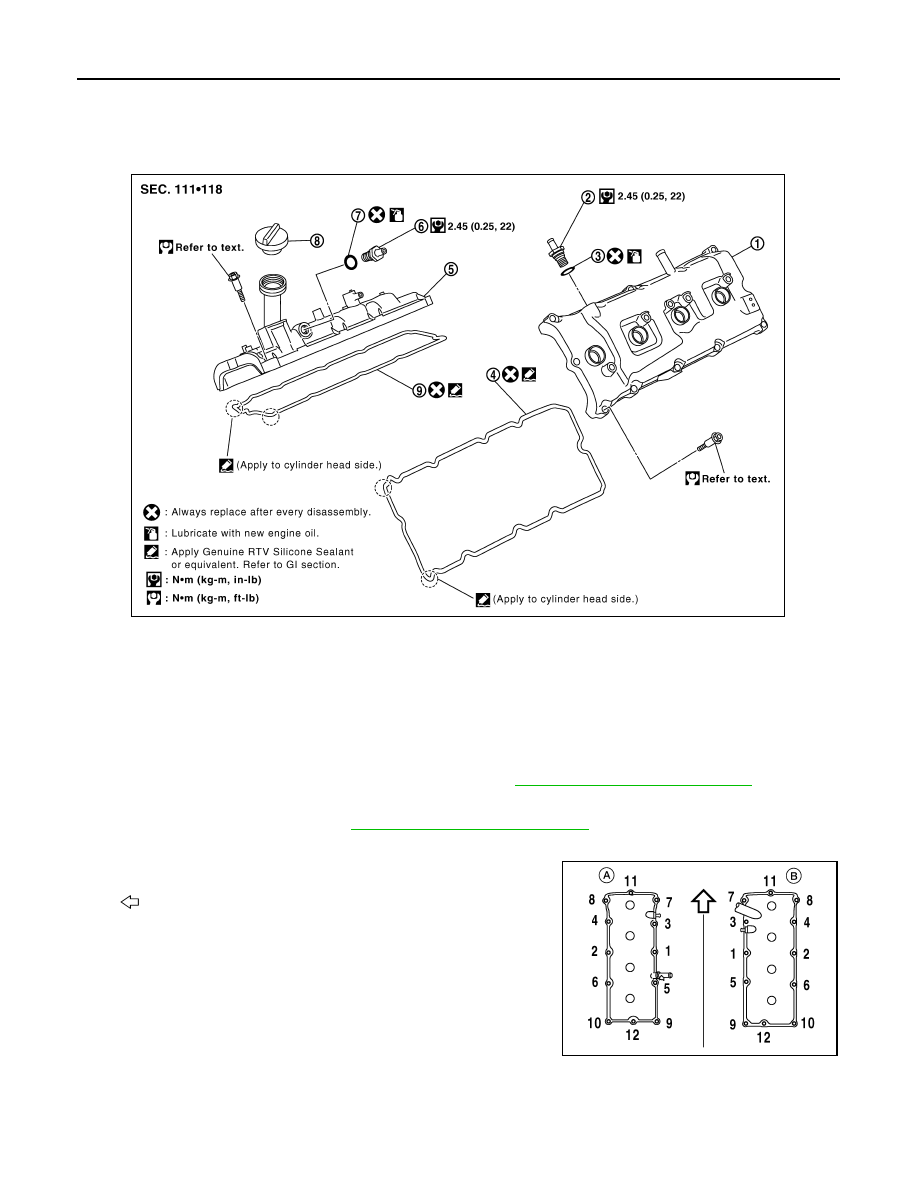

ROCKER COVER

ROCKER COVER

Exploded View

INFOID:0000000005148995

Removal and Installation

INFOID:0000000005148996

REMOVAL

1. Remove the engine room cover using power tool. Refer to

EM-24, "Removal and Installation"

.

2. Move the harness on the upper rocker cover and its peripheral aside.

3. Remove the ignition coils. Refer to

EM-37, "Removal and Installation"

.

4. Remove the PCV hose from the PCV control valves.

5. Loosen the bolts in reverse order shown using power tool for

rocker cover (A) or (B).

•

: Engine front

CAUTION:

Do not hold the rocker cover (RH) (B) by the oil filler neck.

INSTALLATION

1.

Rocker cover (LH)

2.

PCV control valve

3.

O-ring

4.

Rocker cover gasket (LH)

5.

Rocker cover (RH)

6.

PCV control valve

7.

O-ring

8.

Oil filler cap

9.

Rocker cover gasket (RH)

KBIA2508E

WBIA0697E