Infiniti QX56 (JA60). Manual - part 141

C1185 ICC UNIT

BRC-77

< COMPONENT DIAGNOSIS >

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

C1185 ICC UNIT

Description

INFOID:0000000005148057

When the force applied to brake pedal exceeds a certain level, the brake assist is activated and generates a

greater braking force than that of a conventional brake booster, even with light pedal force.

When the ICC preview function identifies the need to apply the sudden brake by sensing the vehicle ahead in

the same lane and the distance and relative speed from it, it applies the brake pre-pressure before driver

depresses the brake pedal and improves brake response by reducing its free play.

DTC Logic

INFOID:0000000005148058

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

CHECK SELF-DIAGNOSIS RESULTS

Check the self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES

>> Proceed to diagnosis procedure. Refer to

.

NO

>> Inspection End

Diagnosis Procedure

INFOID:0000000005148059

Regarding Wiring Diagram information, refer to

BRC-92, "Wiring Diagram - BRAKE CONTROL SYSTEM -"

1.

SELF-DIAGNOSIS RESULT CHECK

Perform self-diagnosis of ICC unit.

Are self-diagnosis result items displayed?

YES

>> After checking and repairing the applicable item, perform ICC unit self-diagnosis again.

NO

>> GO TO 2

2.

CONNECTOR INSPECTION

Disconnect the ABS actuator and electric unit (control unit) connector and the ICC unit connector and check

the terminals for deformation, disconnection, looseness or damage.

Is the inspection result normal?

YES

>> GO TO 3

NO

>> Repair or replace as necessary.

3.

ICC UNIT CIRCUIT INSPECTION

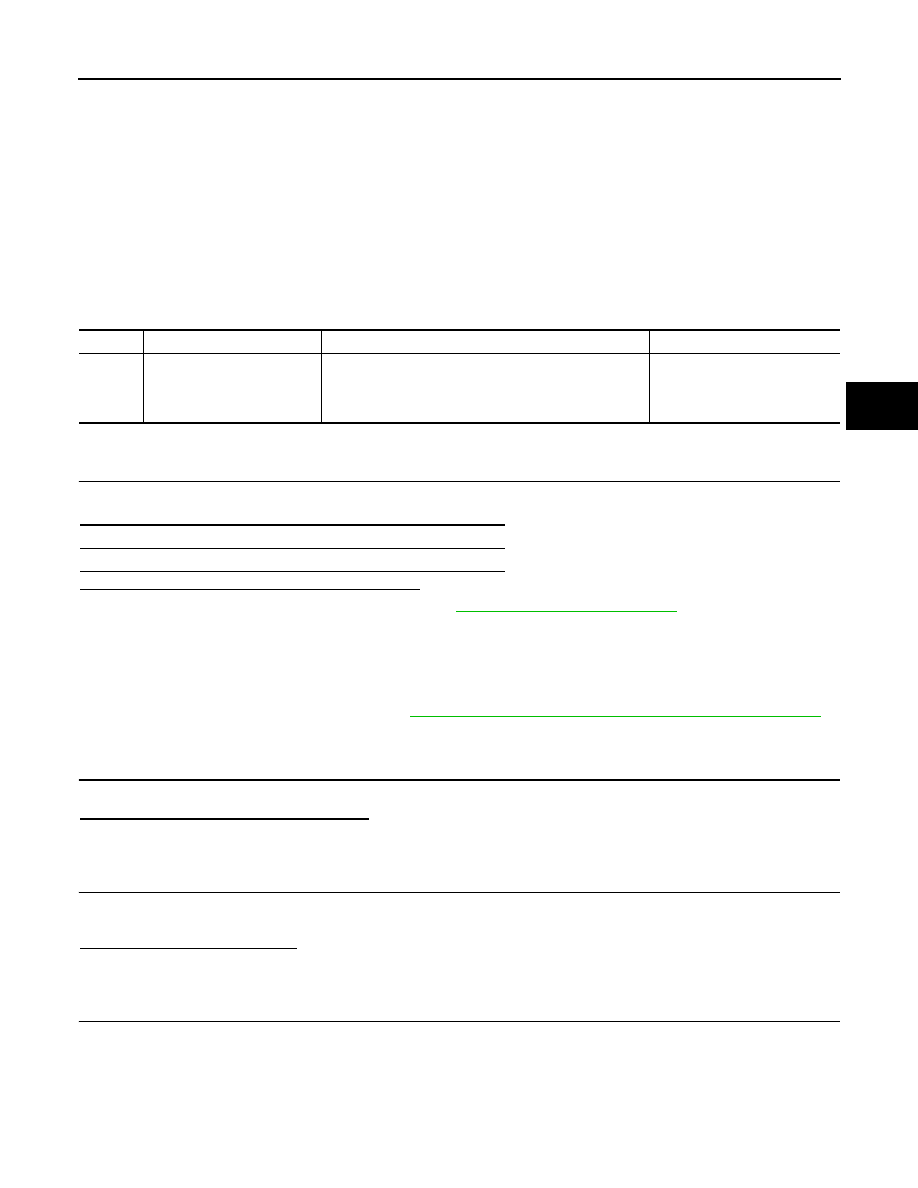

DTC

Display item

Malfunction detected condition

Possible cause

C1185

ABS ACC CU INTERNAL NG ICC control unit internal malfunction.

• Harness or connector

• ICC unit

• ABS actuator and electric unit

(control unit)

Self-diagnosis results

ABS ACC CU INTERNAL NG