Infiniti QX56 (Z62). Manual - part 659

EM-76

< REMOVAL AND INSTALLATION >

CAMSHAFT

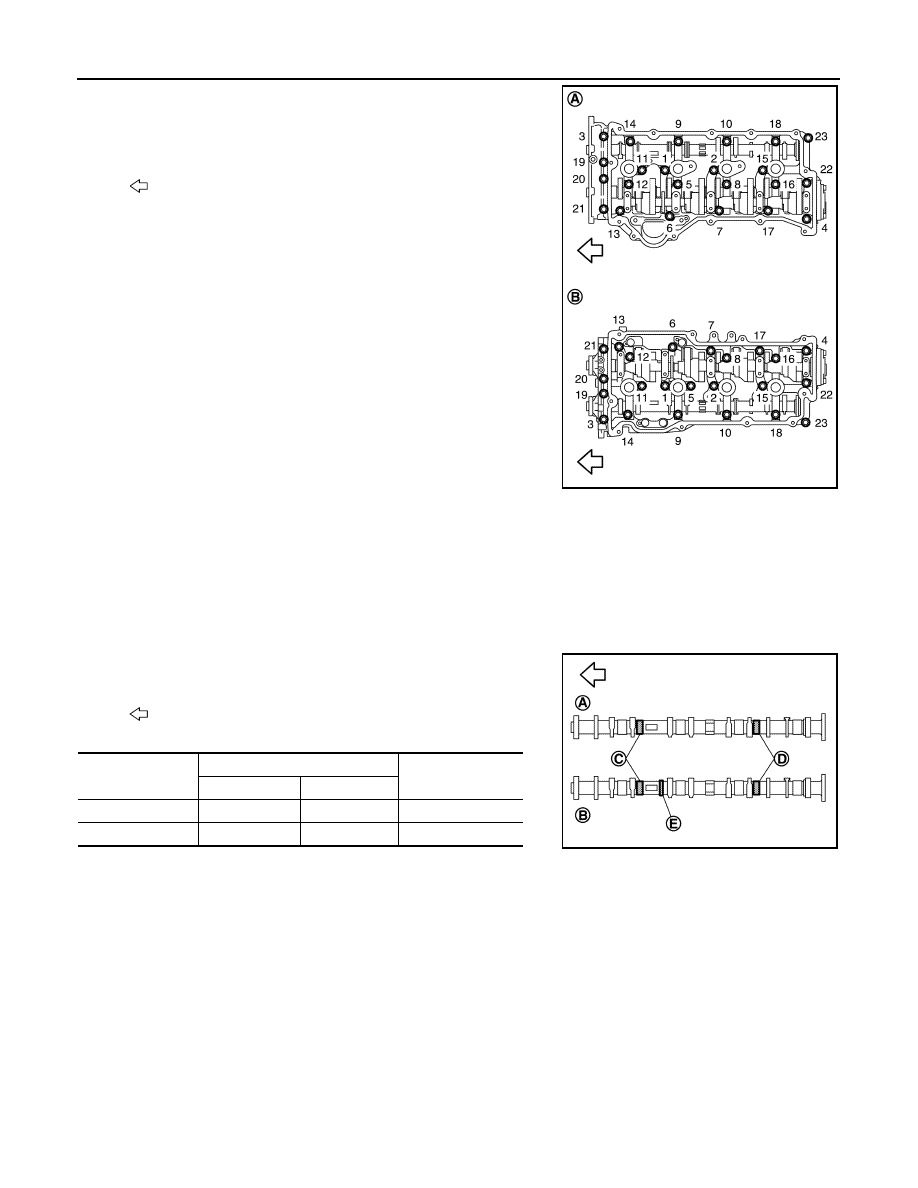

• Loosen mounting bolts (gold color) in the reverse order as

shown in the figure.

CAUTION:

• Never loosen adjusting bolts and mounting bolts (black

color).

• When removing VVEL ladder assembly, hold the drive

shaft from below so as not to drop it.

6.

Remove exhaust camshaft.

7.

Remove valve lifter, if necessary.

• Identify installation positions, and store them without mixing them up.

INSTALLATION

1.

Install valve lifter.

• Install it in the original position.

2.

Install exhaust camshaft.

• Distinction between exhaust camshaft is performed with the

identification mark.

3.

Install VVEL ladder assembly as per the following:

A

: Bank 2

B

: Bank 1

: Engine front

JPBIA3513ZZ

: Engine front

Bank

Paint marks

Identification rib (E)

M1 (C)

M2 (D)

Bank 1 (A)

No

Purple

Yes

Bank 2 (B)

No

Purple

No

JPBIA3514ZZ