Infiniti QX56 (Z62). Manual - part 446

DLK-250

< REMOVAL AND INSTALLATION >

KEY CYLINDER

KEY CYLINDER

GLOVE BOX LID KEY CYLINDER

GLOVE BOX LID KEY CYLINDER : Removal and Installation

INFOID:0000000006226112

REMOVAL

1.

Remove glove box assembly. Refer to

IP-14, "Removal and Installation"

2.

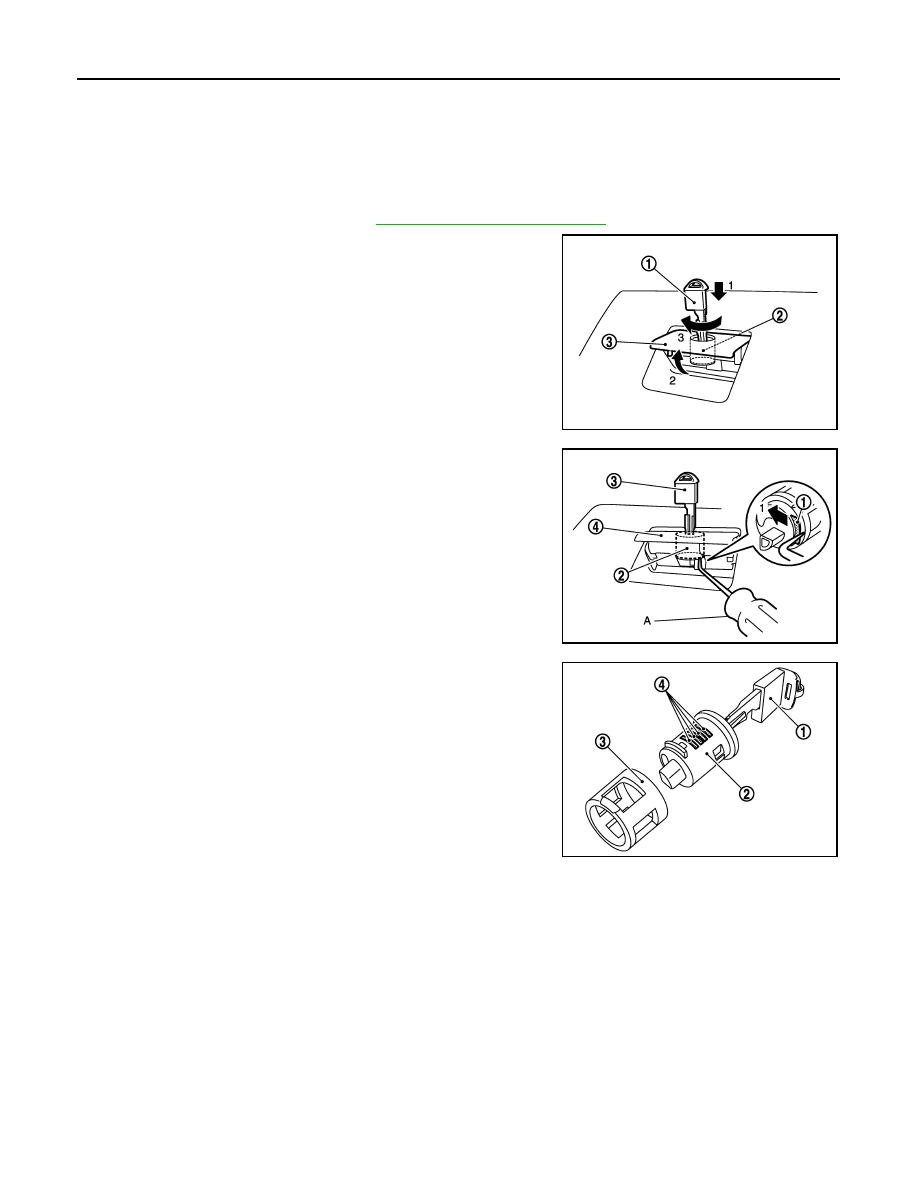

Insert mechanical key (1) into glove box lid lock cylinder (2).

3.

Set glove box lid release handle (3) to the pulled-up status.

4.

Rotate mechanical key and turn glove box lid key cylinder to the

lock position.

5.

Press tumbler stopper (1) into glove box lid lock cylinder (2)

using a hook and pick tool (A), and then remove mechanical key

(3) and glove box lid lock cylinder together from glove box lid

release handle (4).

NOTE:

When removing glove box lid lock cylinder, write a short note

describing its position against glove box lid release handle.

6.

Remove sleeve (3) from glove box lid release handle, and then

install sleeve to glove box lid lock cylinder.

NOTE:

When removing sleeve, write a short note describing its position

against glove box lid release handle.

CAUTION:

Never pull out mechanical key (1) from glove box lid lock

cylinder (2) while sleeve is uninstalled. Otherwise, tumbler

(4) pops out of glove box lid lock cylinder.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

After installation, check glove box assembly open/close, lock/unlock operation.

JMKIA5490ZZ

JMKIA5491ZZ

JMKIA5819ZZ