Infiniti Q45. Manual - part 99

ASSEMBLY

AT-309

D

E

F

G

H

I

J

K

L

M

A

B

AT

b.

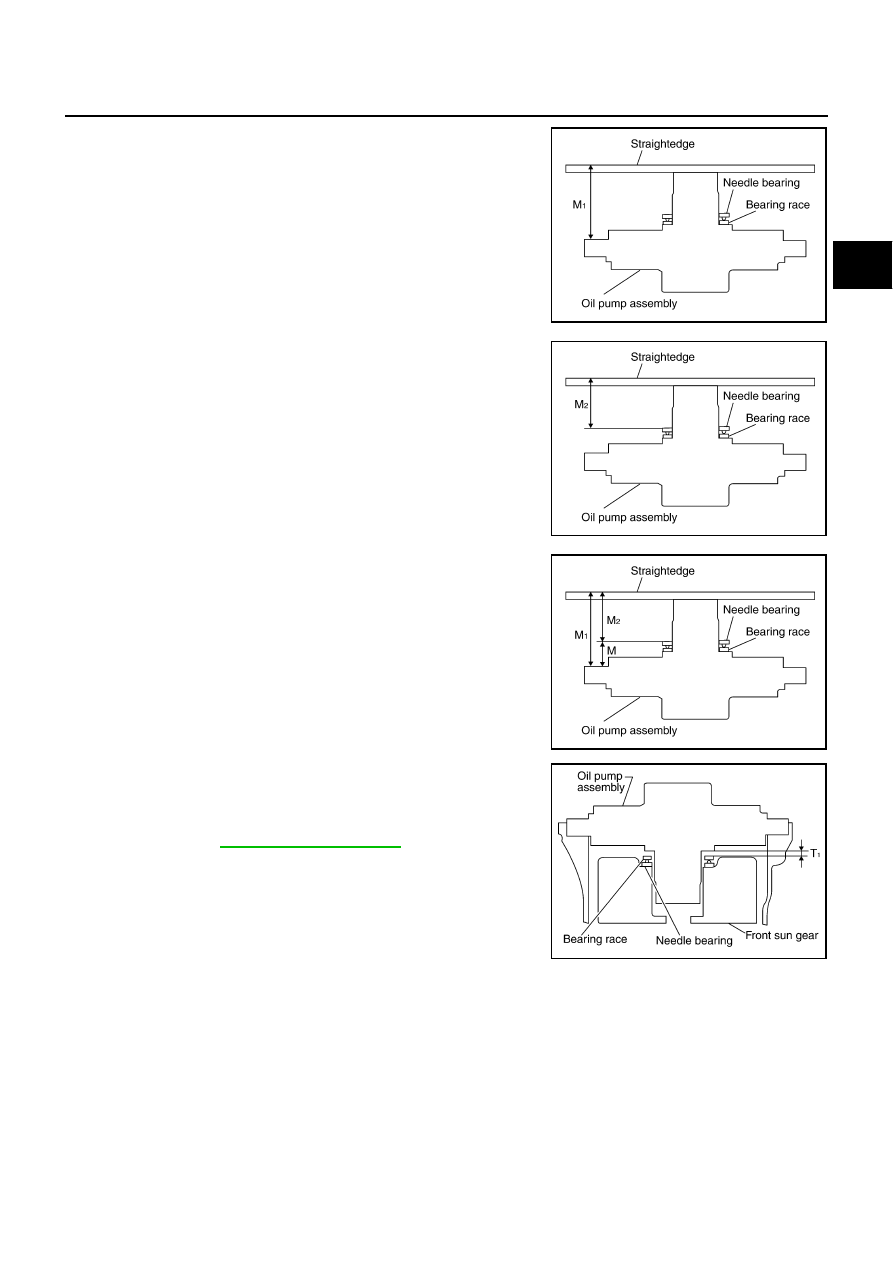

Measure dimension “M

1

”.

c.

Measure dimension “M

2

”.

d.

Calculate dimension “M”.

3.

Adjust total end play “T

1

”.

●

Select proper thickness of bearing race so that total end play

is within specifications. Refer to “Parts Information” for bear-

ing race selection.

SCIA3126E

SCIA3127E

“M”: Distance between transmission case fitting sur-

face of oil pump and needle bearing on oil pump.

M = M

1

– M

2

SCIA3125E

T

1

= J – M

Total end play “T

1

”:

Refer to

SCIA2810E