Infiniti G37 Coupe. Manual - part 632

CYLINDER HEAD

EM-103

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

b.

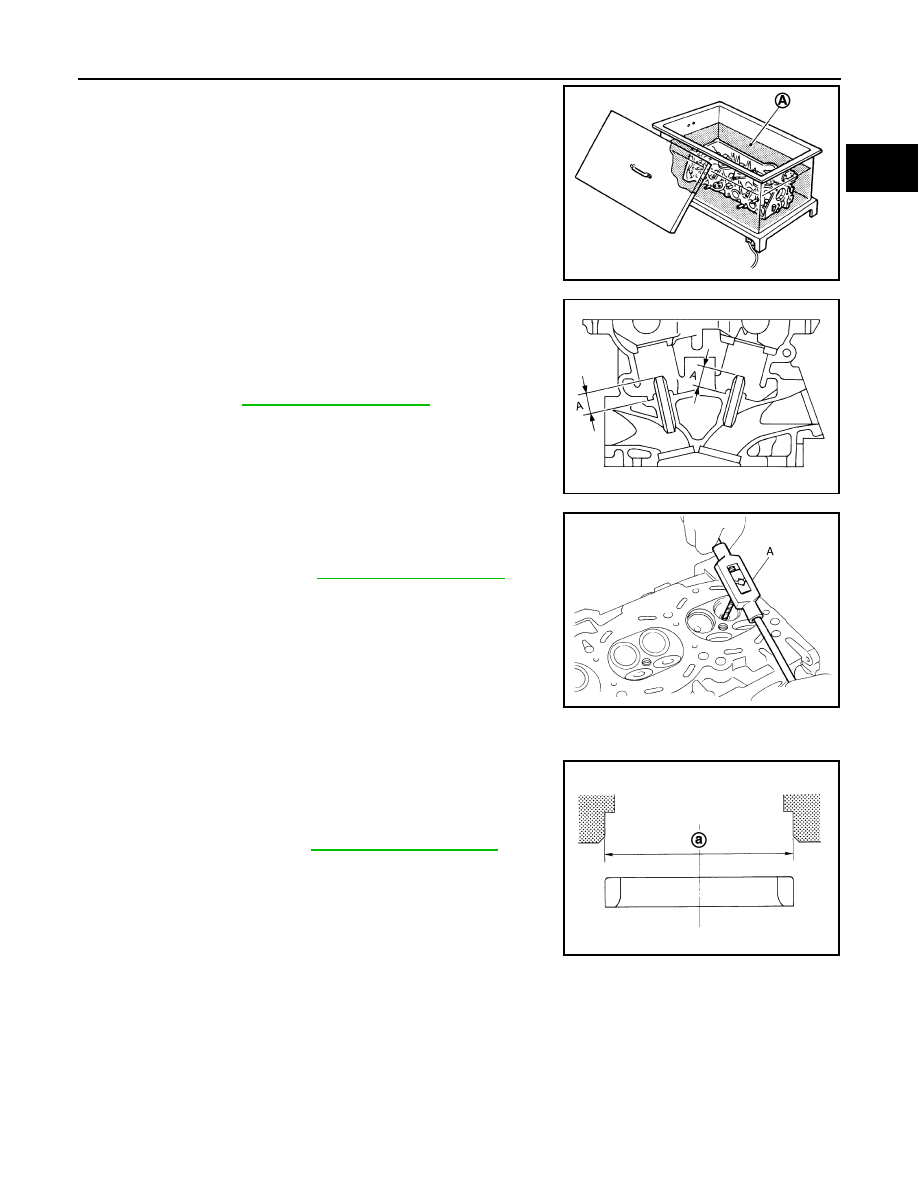

Heat cylinder head to 110 to 130

°

C (230 to 266

°

F) by soaking in

heated oil (A).

c.

Using the valve guide drift (commercial service tool), press valve

guide (EXH) from camshaft side to the dimensions as shown in

the figure.

WARNING:

Cylinder head contains heat. When working, wear protec-

tive equipment to avoid getting burned.

d.

Using the valve guide reamer (commercial service tool) (A),

apply reamer finish to valve guide (EXH).

2.

If valve seat (EXH) is removed in step 10 (DISASSEMBLY), install it.

Replace with oversize [0.5 mm (0.020 in)] valve seat (EXH).

a.

Ream cylinder head recess diameter (a) for service valve seat

(EXH).

• Be sure to ream in circles concentric to valve guide center.

This will enable valve to fit correctly.

JPBIA0184ZZ

Projection (A)

: Refer to

JPBIA0186ZZ

Standard

: Refer to

.

JPBIA0185ZZ

Oversize (service) [0.5 mm (0.020 in)]:

: Refer to

.

JPBIA0188ZZ