Content .. 1291 1292 1293 1294 ..

Infiniti G37 Coupe. Manual - part 1293

TRANSMISSION ASSEMBLY

TM-25

< REMOVAL AND INSTALLATION >

[6MT: FS6R31A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

REMOVAL AND INSTALLATION

TRANSMISSION ASSEMBLY

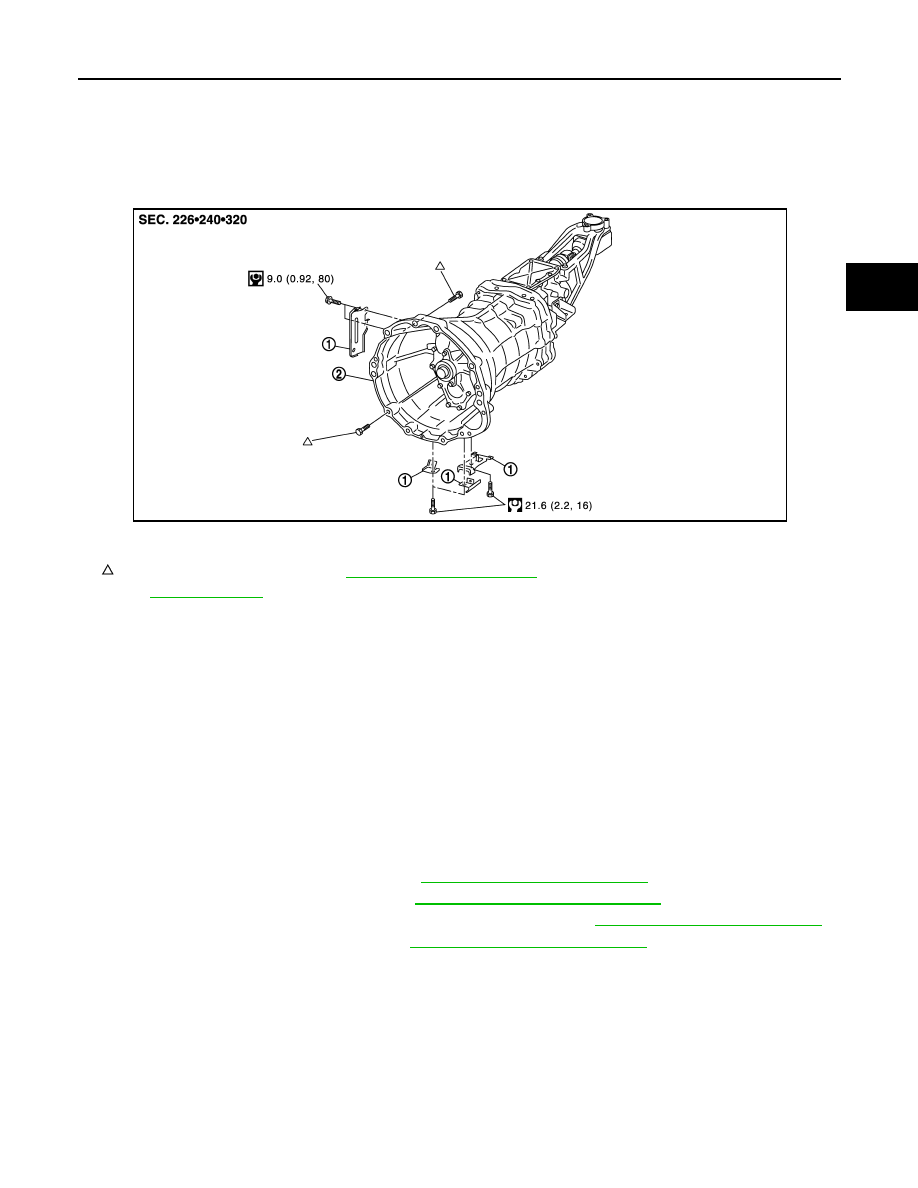

Exploded View

INFOID:0000000001732877

CAUTION:

If transmission assembly is removed from the vehicle, always replace CSC (Concentric Slave Cylinder) body and CSC tube.

Return CSC body insert to original position to remove transmission assembly. Dust on clutch disc sliding parts may damage

seal of CSC body and may cause clutch fluid leakage.

Removal and Installation

INFOID:0000000001732878

CAUTION:

If transmission assembly is removed from the vehicle, always replace CSC (Concentric Slave Cylin-

der) body and CSC tube. Return CSC body insert to original position to remove transmission assem-

bly. Dust on clutch disc sliding parts may damage seal of CSC body and may cause clutch fluid

leakage.

REMOVAL

1.

Disconnect the battery cable from the negative terminal.

2.

Remove exhaust mounting bracket. Refer to

EX-6, "Removal and Installation"

3.

Remove suspension member stay. Refer to

FSU-24, "Removal and Installation"

4.

Remove exhaust front tube, center muffler, and main muffler. Refer to

EX-6, "Removal and Installation"

5.

Remove propeller shaft assembly. Refer to

DLN-7, "Removal and Installation"

.

NOTE:

Insert a suitable plug into rear oil seal of transmission assembly after removing propeller shaft assembly.

6.

Remove control lever assembly with the following procedure.

1.

Harness bracket

2.

Transmission assembly

: For the bolt mounting positions, refer to

TM-25, "Removal and Installation"

.

Refer to

for symbols not described on the above.

JPDIC0158GB