Infiniti FX35 / FX45. Manual - part 897

RSU-4

< SERVICE INFORMATION >

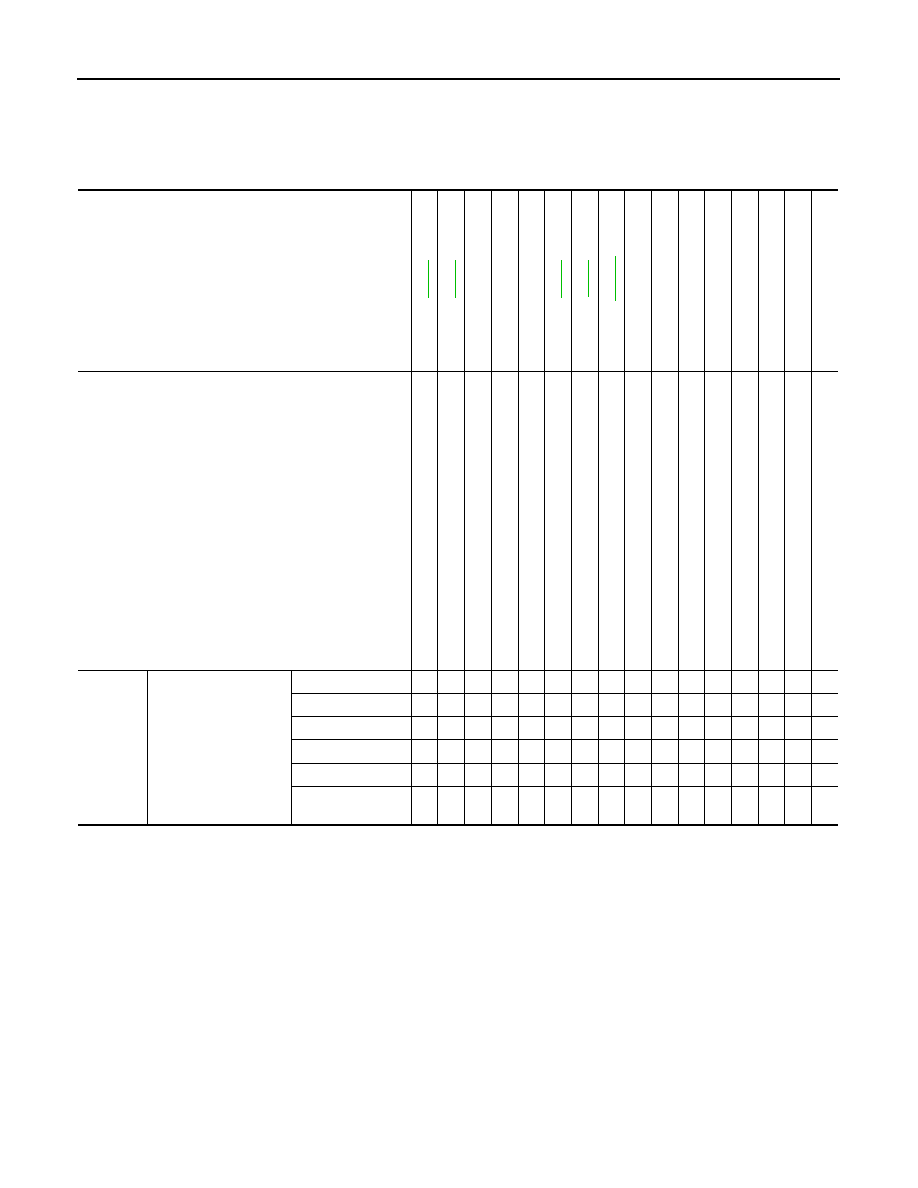

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

INFOID:0000000001327551

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference page

—

—

—

NVH in PR

section

NVH in RFD

section

NVH in RAX

and RSU

section

NVH in WT

section

NVH in WT

section

NVH in RAX

section

NVH in BR

section

NVH in PS

section

Possible cause and SUSPECTED PARTS

Imp

rop

er i

ns

ta

lla

ti

o

n,

lo

os

en

es

s

Sh

oc

k

ab

so

rbe

r de

form

a

tio

n,

dam

a

g

e

or d

e

flec

ti

on

Bu

sh

in

g o

r m

o

u

n

ti

ng

de

teri

ora

tio

n

Part

s interf

erence

S

p

rin

g

f

a

ti

gu

e

Su

sp

en

si

on

lo

os

en

es

s

In

co

rrec

t wh

ee

l a

lig

nm

en

t

S

tab

ili

ze

r ba

r fa

tig

u

e

PROPELLER S

H

AFT

DIFF

ERENTIAL

REAR A

X

LE

AND REAR SUSP

ENSION

TI

RE

ROAD

WHEEL

DRIVE SHAFT

BRAKE

STE

E

RING

Symptom

REAR SUSPENSION

Noise

×

×

×

×

×

×

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

×

×

×

×

Vibration

×

×

×

×

×

×

×

×

×

×

Shimmy

×

×

×

×

×

×

×

×

×

×

Judder

×

×

×

×

×

×

×

×

Poor quality ride or

handling

×

×

×

×

×

×

×

×

×

×