Infiniti EX35. Manual - part 862

TRANSVERSE LINK

FSU-33

< ON-VEHICLE REPAIR >

[AWD]

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

NOTE:

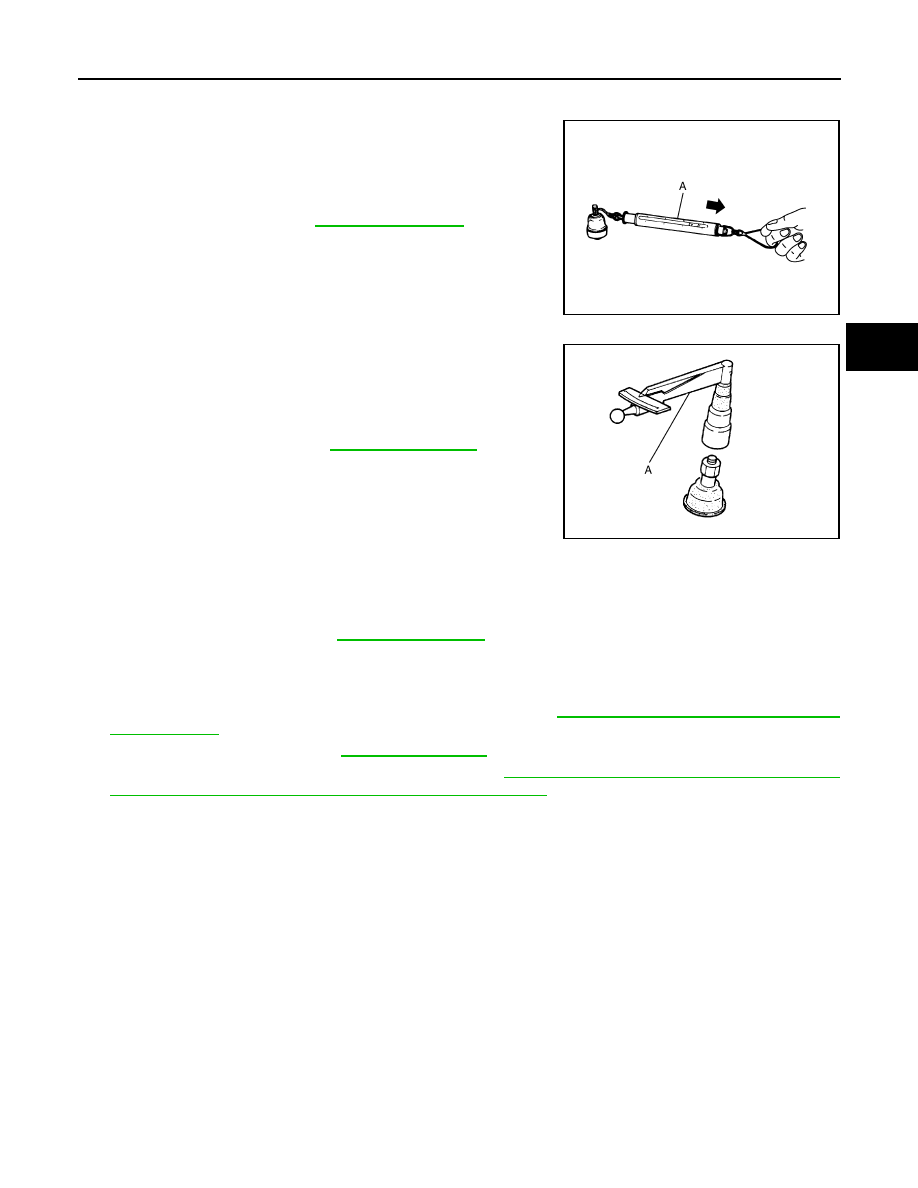

Before measurement, move ball stud at least ten times by hand to check for smooth movement.

• Hook a spring balance (A) at cotter pin mounting hole. Confirm

spring balance measurement value is within specifications when

ball stud begins moving.

- If swing torque exceeds standard range, replace transverse link

assembly.

Rotating Torque Inspection

• Attach mounting nut to ball stud. Make sure that rotating torque is

within specifications with a preload gauge (A) [SST: 3127S000 (J-

25765-A)].

- If rotating torque exceeds standard range, replace transverse link

assembly.

Axial End Play Inspection

• Move tip of ball stud in axial direction to check for looseness.

- If axial end play exceeds standard range, replace transverse link assembly.

INSPECTION AFTER INSTALLATION

1.

Check wheel sensor harness for proper connection. Refer to

BRC-107, "FRONT WHEEL SENSOR :

.

2.

Check wheel alignment. Refer to

3.

Adjust neutral position of steering angle sensor. Refer to

BRC-8, "ADJUSTMENT OF STEERING ANGLE

SENSOR NEUTRAL POSITION : Special Repair Requirement"

.

Standard

Swing toque

JPEIA0005ZZ

Standard

Rotating toque

: Refer to

.

PDIA1258E

Standard

Axial end play

:Refer to

.