Infiniti EX35. Manual - part 860

PREPARATION

FSU-25

< PREPARATION >

[AWD]

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

PREPARATION

PREPARATION

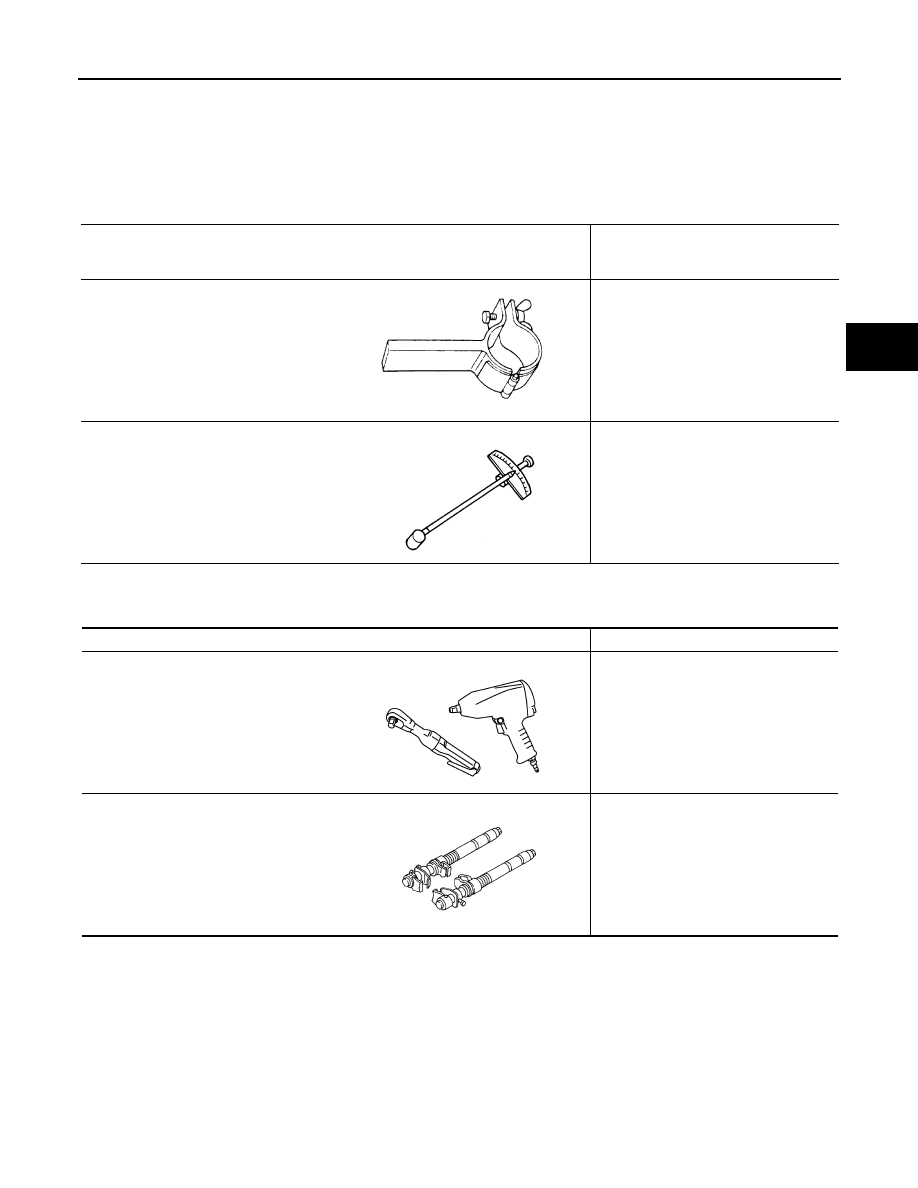

Special Service Tool

INFOID:0000000003129930

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tool

INFOID:0000000003129931

Tool number

(Kent-Moore No.)

Tool name

Description

ST35652000

(

–

)

Strut attachment

Disassembling and assembling strut

ST3127S000

(J-25765-A)

Preload gauge

Measuring rotating torque of ball joint

ZZA0807D

ZZA0806D

Tool name

Description

Power tool

Loosening bolts and nuts

Spring compressor

Removing and installing coil spring

PBIC0190E

S-NT717