Infiniti EX35. Manual - part 858

FRONT STABILIZER

FSU-17

< ON-VEHICLE REPAIR >

[2WD]

C

D

F

G

H

I

J

K

L

M

A

B

FSU

N

O

P

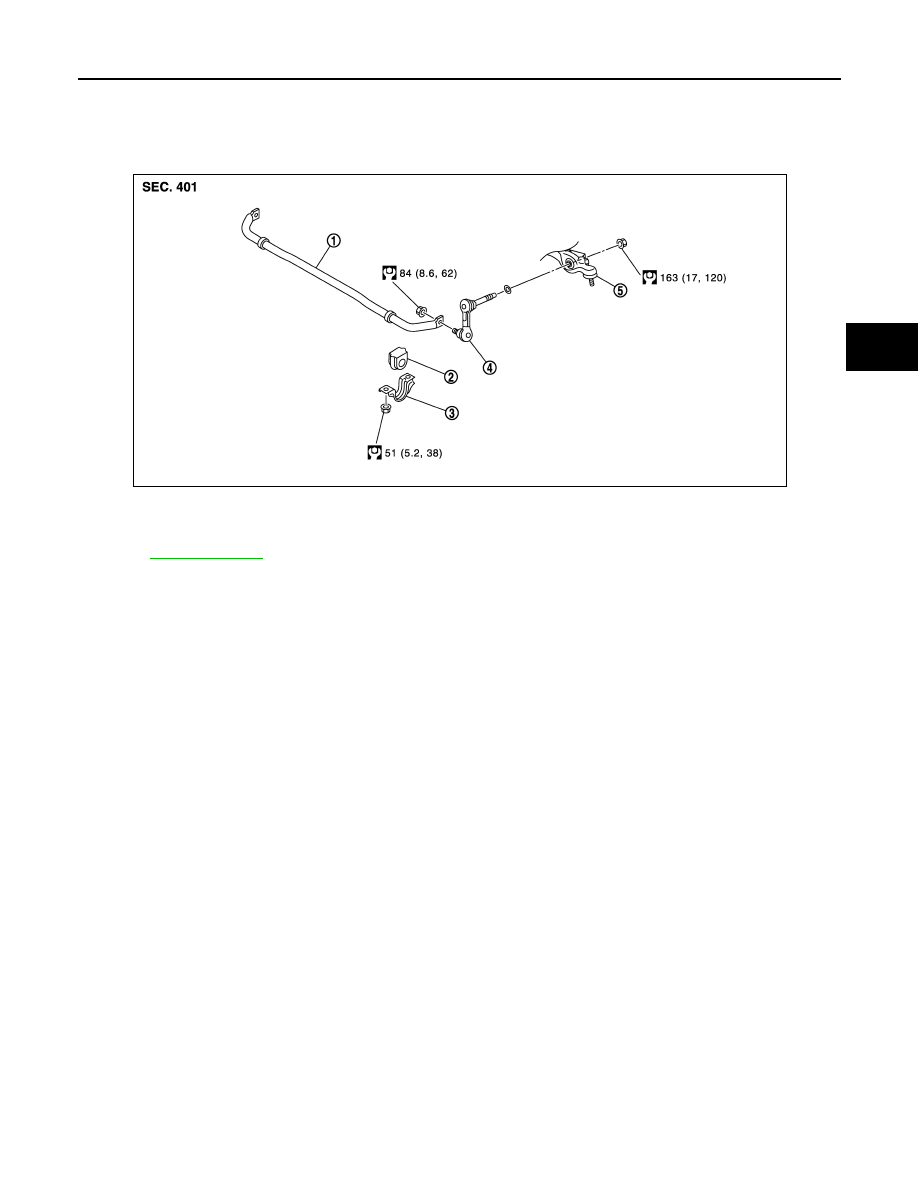

FRONT STABILIZER

Exploded View

INFOID:0000000003129913

Removal and Installation

INFOID:0000000003129914

REMOVAL

1.

Remove tires with power tool.

2.

Remove under cover with power tool.

3.

Remove stabilizer connecting rod with power tool.

CAUTION:

Apply a matching mark to identify the installation position.

4.

Remove stabilizer clamp and stabilizer bushing.

5.

Remove stabilizer bar.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Check the matching mark when installing.

• Tighten the mounting nut to the specified torque while holding a hexagonal part of stabilizer connecting rod

side.

Inspection

INFOID:0000000003129915

INSPECTION AFTER REMOVAL

Check stabilizer bar, stabilizer connecting rod, stabilizer bushing and stabilizer clamp for deformation, cracks

or damage. Replace it if necessary.

1.

Stabilizer bar

2.

Stabilizer bushing

3.

Stabilizer clamp

4.

Stabilizer connecting rod

5.

Transverse link

Refer to

JPEIA0084GB