Ford F150 Pickup. Instruction - part 337

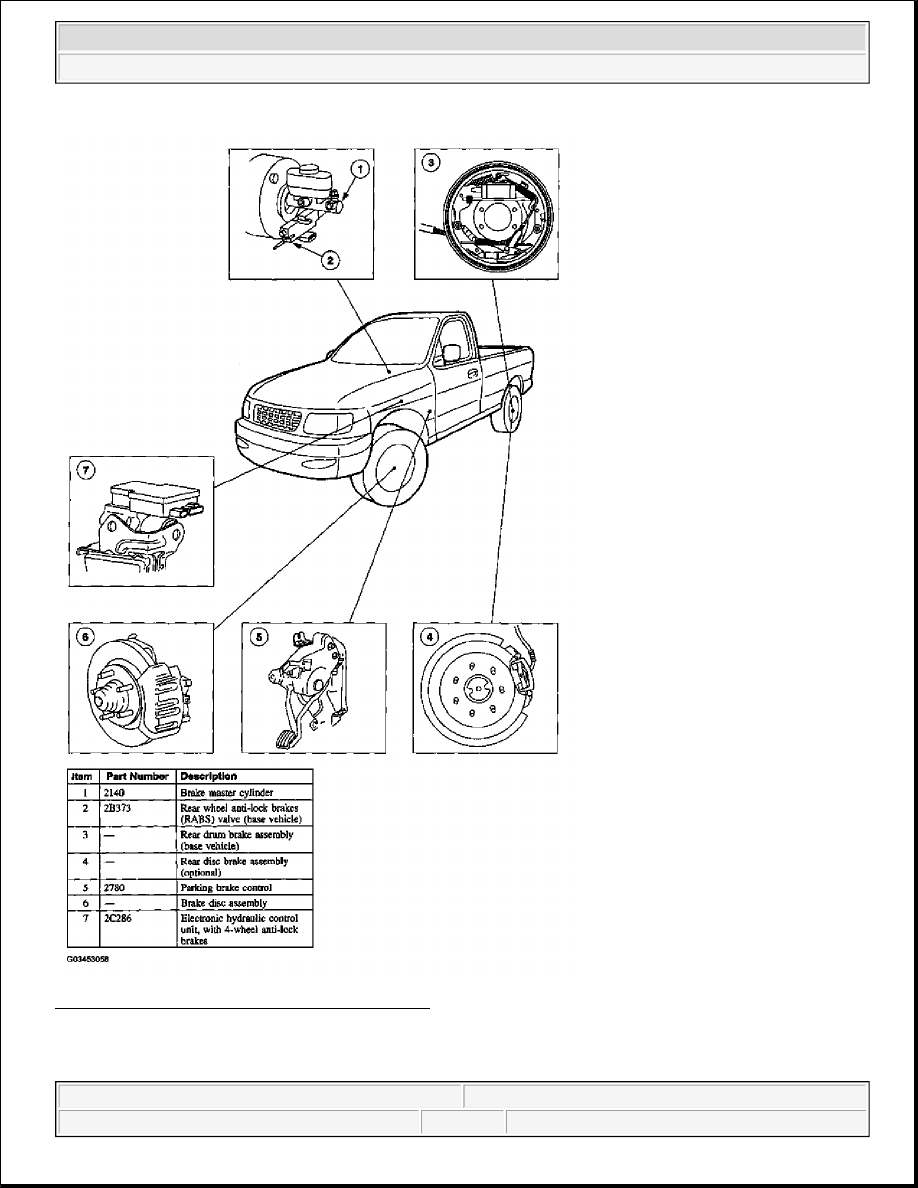

Fig. 1: Brake System Description And Operation

Courtesy of FORD MOTOR CO.

z

The vehicle is equipped with a vacuum-assisted power braking system.

2003 Ford Pickup F150

2003 GENERAL INFORMATION Brake System - General Information - F150 Pickup