Content .. 1296 1297 1298 1299 ..

Ford F150 Pickup. Instruction - part 1298

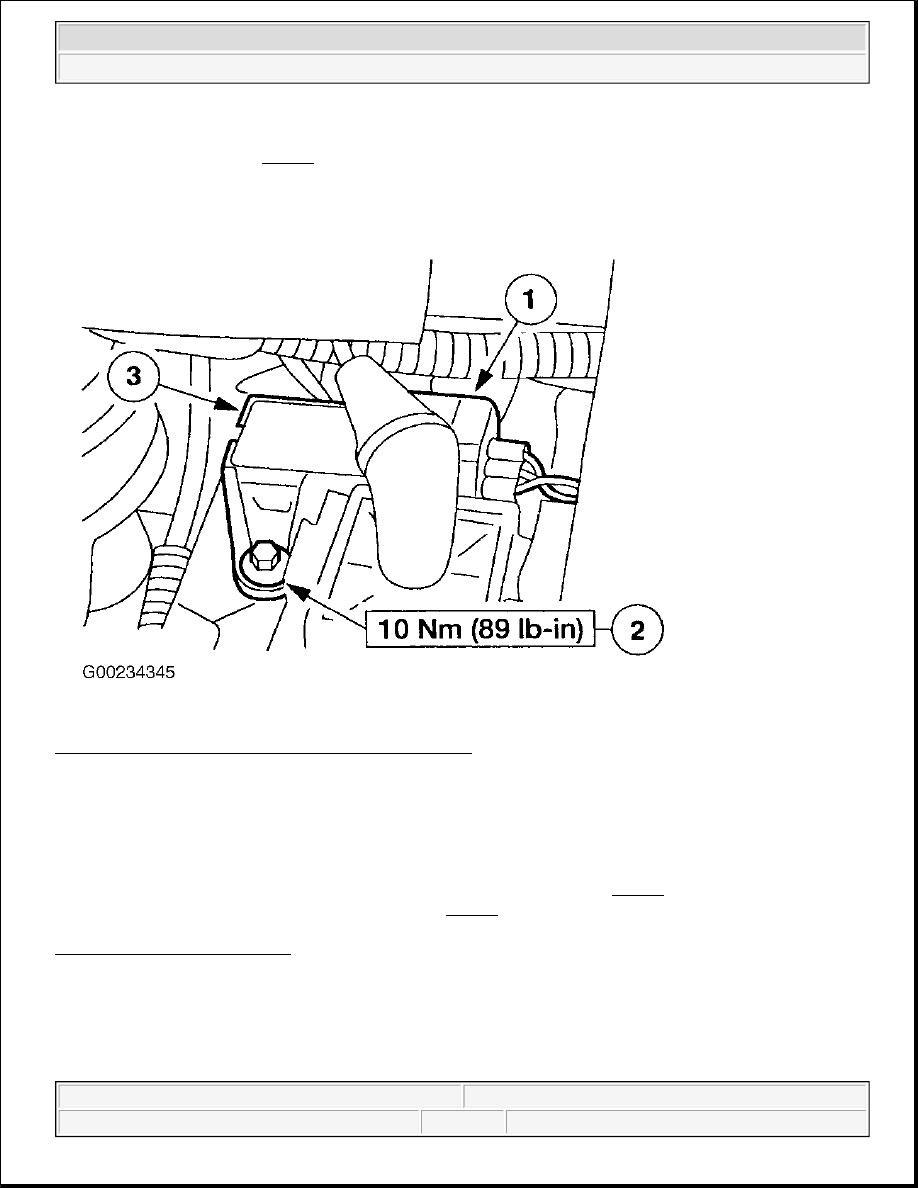

Barometric (BARO) pressure sensor is located on right side of engine compartment. Disconnect BARO sensor

electrical connector (1). See Fig. 57 . Remove retaining bolt (2) and remove BARO sensor (3). To install,

reverse removal procedure.

Fig. 57: Removing BARO Sensor (5.4L Supercharged)

Courtesy of FORD MOTOR CO.

CAMSHAFT POSITION SENSOR

Removal & Installation (4.6L & 5.4L)

Camshaft Position (CMP) sensor is located at front of left cylinder head. See Fig. 54 . Disconnect negative

battery cable. Disconnect CMP sensor connector. See Fig. 58 . Remove CMP sensor mounting bolt. Remove

CMP sensor. To install, reverse removal procedure. Tighten CMP sensor mounting bolts to specification. See

TORQUE SPECIFICATIONS .

2003 Ford Pickup F150

2003 ENGINE PERFORMANCE Removal & Installation - Blackwood, Expedition, F150 Pickup & Navigator - Gasoline