Content .. 1279 1280 1281 1282 ..

Ford F150 Pickup. Instruction - part 1281

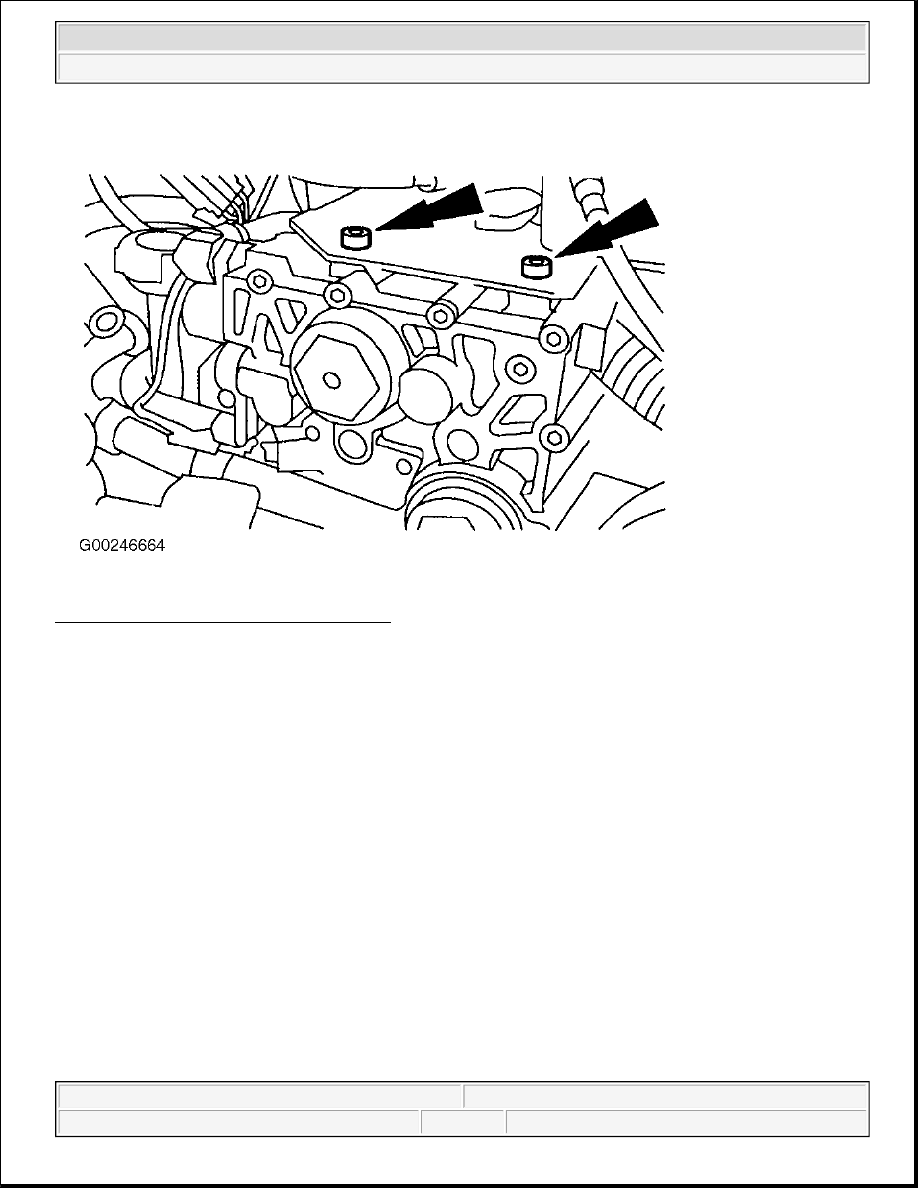

Fig. 20: Locating Vaporizer Retaining Bolts

Courtesy of FORD MOTOR CO.

ADJUSTMENTS

FUEL RAIL (TUNABLE "T")

1. Park vehicle on flat surface, set parking brake and place wheel chocks both in front of and behind front

wheels. Turn ignition switch to OFF position. Place ALT/GAS switch to ALT position. Connect a

vacuum gauge to intake manifold vacuum.

2. Connect New Generation Star (NGS) Tester (418-F048), to vehicle Data Link Connector (DLC). Turn the

ignition switch to ON position. Select, monitor, and record Powertrain Control Module (PCM) PIDs;

ECT, O2S1/1 and O2S2/1. Start and run engine while monitoring ECT PID. Allow engine to warm up

until ECT PID reads 190°F (88°C).

3. Select, monitor, and record Alternate Fuel Control Module (AFCM) MAP PID and engine vacuum. Place

transmission in Reverse while applying brake pedal then slowly apply pressure to accelerator pedal.

WARNING:

The following step requires engine to be running, in gear and at high

RPM. Ensure parking brake is fully set and wheels are chocked. Use

all necessary precautions to avoid personal injury, or property

and/or equipment damage.

2003 Ford Pickup F150

2003 ENGINE PERFORMANCE Removal & Installation - F150 Pickup - Bi-Fuel - Gasoline/LPG