Daewoo Korando. Manual - part 41

1B1-100 M162 ENGINE MECHANICAL

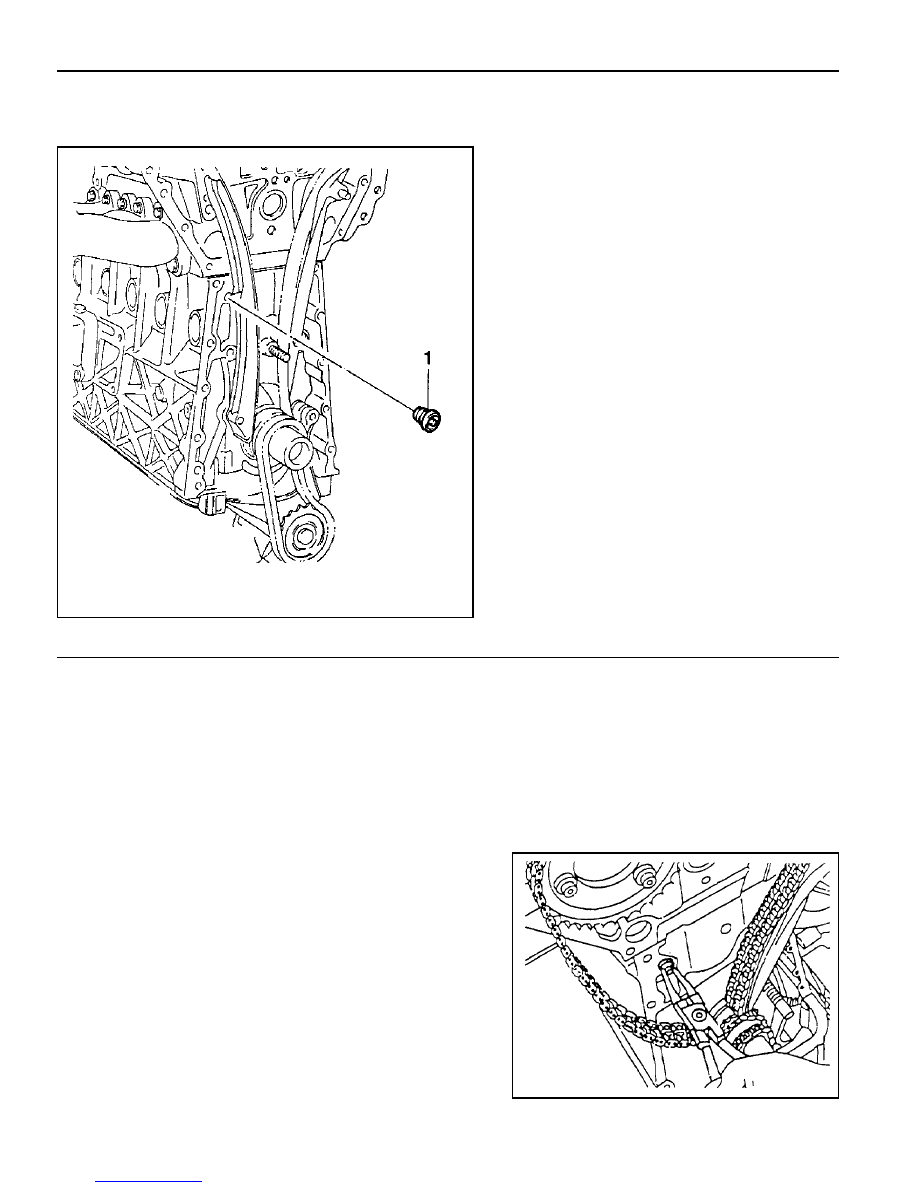

OIL NON-RETURN VALVE

Preceding Work : Removal of timing gear case cover

1 Oil Non-return Valve

Functions

The non-return valve prevents the oil in the chain tensioner

from drying up. In other words, it stops oil-returning in order to

prevent the oil in the chain tensioner from getting dry. As a

result, the chain tensioner can be activated with oil in itself.

Replacement Procedure

1. Remove the non-return valve using a pliers.

2. Insert new non-return valve with hand.