Daewoo Korando. Manual - part 32

1B1-64 M162 ENGINE MECHANICAL

Adjustment Procedure

1. Position the No.1 cylinder to BTDC 30° .

2. Remove the chain tensioner.

3. Remove the exhaust camshaft sprocket.

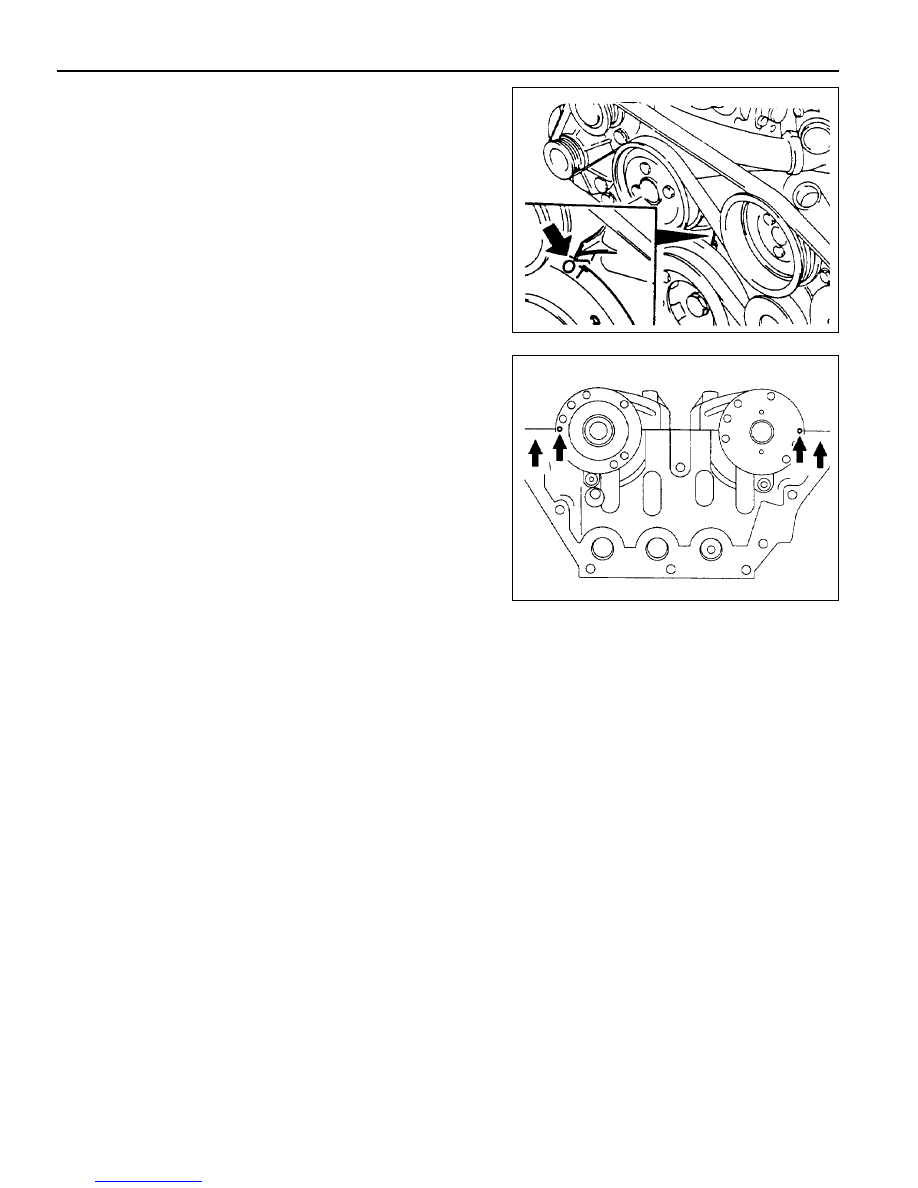

4. Align the intake and exhaust camshaft flange hole with the

cylinder head upper surface.

l

Intake Side : 3 o’clock direction

l

Exhaust Side : 9 o’clock direction

5. Secure the intake and exhaust camshaft.

6. Position the piston of No.1 cylinder at TDC (OT) by turning

the crankshaft.

7. Turn the camshaft adjuster of the intake camshaft to the

left as much as possible (cam adjuster ‘retarded’ position).

8. Install the chain to the intake camshaft sprocket.

Notice

Timing chain must be placed on the guide rail in gear case

cover.

Tools Required

104 589 01 01 00 Spanner

Inspection

1. Position the No.1 cylinder piston to TDC (OT) by turning

the crankshaft.

Notice

When the OT mark on vibration damper is aligned with timing

gear case cover, the intake and exhaust cam of cylinder

will make the slope to the center and will face up. In this

way, the adjustment hole of the intake and exhaust camshaft

will match in line with the cylinder head upper end, at 3

o’clock, and 9 o’clock direction each other.

2. Check the timing as below procedure;

-

Check if the camshaft adjustment hole is positioned to 3

o’clock direction at the intake side and to 9 o’clock

direction at the exhaust side, respectively and align with

the cylinder head mating surface.

-

At this condition, check if the OT mark on vibration

damper aligns with the marker on the timing gear case.