DAF CF65, CF75, CF85 Series . Manual - part 997

©

200423

2-5

Inspection and adjustment

STEERED TRAILING SWIVEL AXLE

ΧΦ65/75/85 series

7

7

2.2 INSPECTION AND ADJUSTMENT, CASTER

Inspection of caster

1.

Place the vehicle on a level and horizontal

surface.

2.

Put the trailing axle in the "straight ahead"

position.

3.

Use high-quality wheel alignment equipment

for the inspection. The equipment must be

calibrated regularly and preferably be of the

type that can be calibrated before every use.

4.

Follow the instructions for the wheel

alignment equipment carefully.

5.

Compare the reading with the specified

value. See 'Technical data'.

6.

Carry out the caster measurement on the

other axle side too.

If different readings are obtained, the axle

suspension should also be inspected for

deviations.

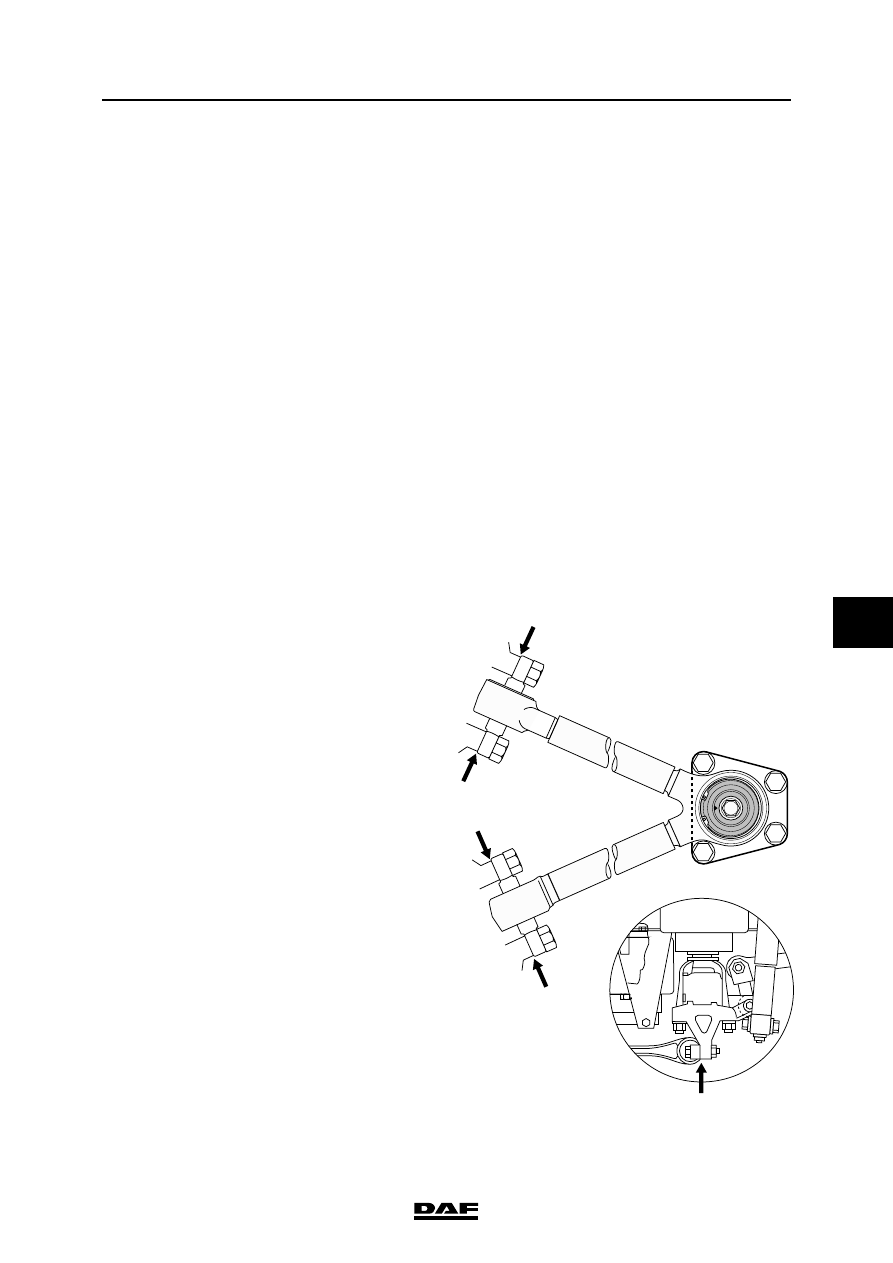

Adjusting the caster

1.

Adjust the caster by fitting hardened steel

washers between attachment of the torque

rods or the triangular link

(DAF no. 0202838). The washers are 3 mm

thick. Grind the washers if necessary. The

application of more than one washer per bolt

is not acceptable.

2.

Repeat the measurement once the steel

washers have been fitted.

S7 00 728