DAF CF65, CF75, CF85 Series . Manual - part 996

©

200423

2-1

Inspection and adjustment

STEERED TRAILING SWIVEL AXLE

ΧΦ65/75/85 series

7

7

2. INSPECTION AND ADJUSTMENT

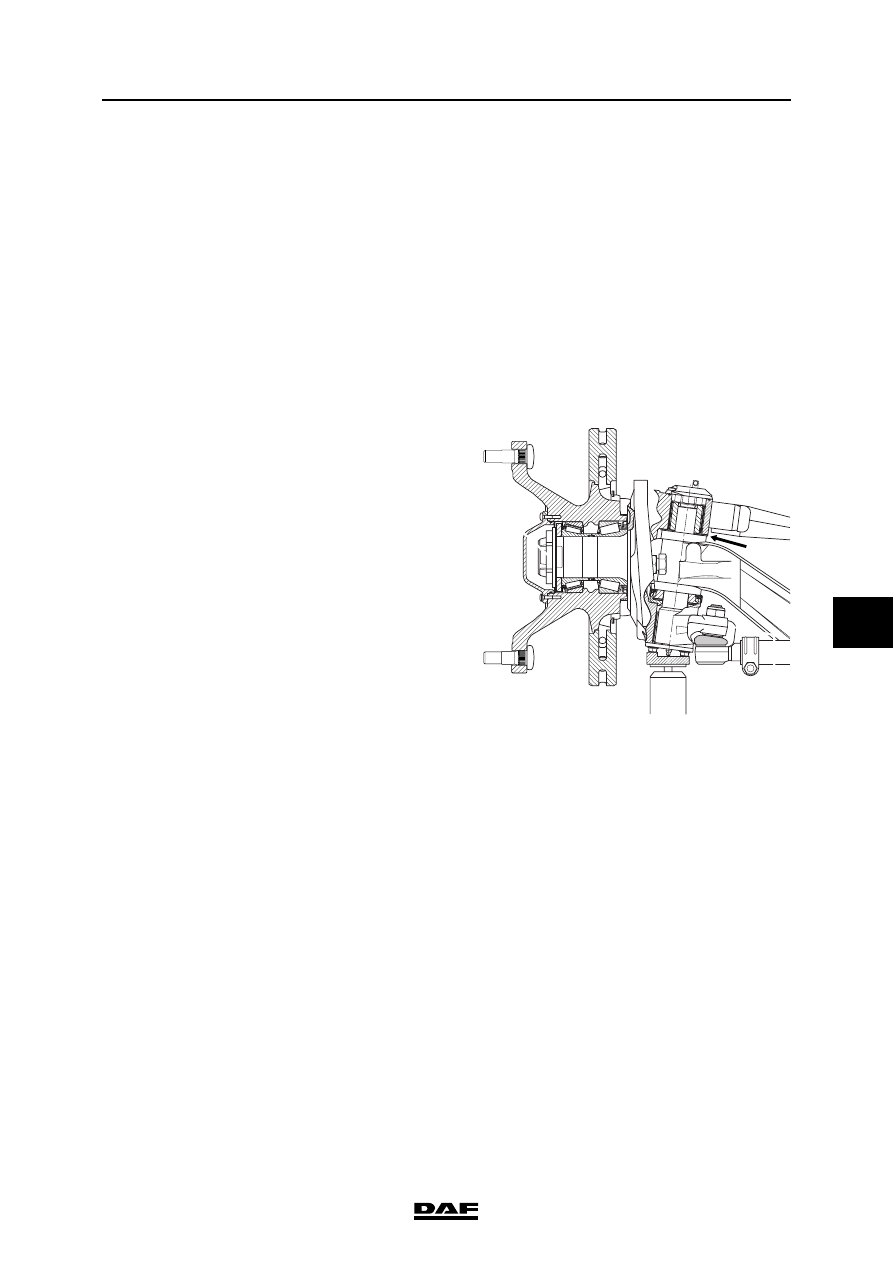

2.1 INSPECTION AND ADJUSTMENT, SWIVEL AXLE PLAY

Inspection of swivel axle play

1.

The vehicle should have its wheels on the

ground.

Note:

If the wheels have been removed from the

front axle, e.g. for overhaul purposes, the

swivel axle will hang at the axle end.

In that case, the swivel axle should be

supported by a jack, pushing the swivel axle

against the bottom of the axle end.

2.

Using a feeler gauge measure the distance

between the shim and the swivel axle at (A).

Take measurements in several places.

Compare the reading with the admissible

play. See 'Technical data'.

Note:

The play should be about equal along the

entire circumference of the axle end. If the

play is not equal, this is caused by radial play

in the needle bearings. If the radial play of

one of the values measured along the

circumference differs from the specified

value, the needle bearings should be

replaced, see the chapter 'Removal and

installation'.

If an excessive axial play is measured along

the entire circumference of the axle end, this

is probably caused by a worn swivel axle

thrust bearing.

Adjusting the swivel axle play, thrust bearing,

split version

1.

Remove the swivel axle from the axle end.

See 'Removal and installation'.

2.

Degrease and clean the thrust bearing.

3.

Check the thrust bearing for wear or

damage. If in doubt, replace the thrust

bearing.

4.

Check the machined surfaces of the axle end

and the swivel axle for damage.

A

S7 00 579