DAF CF65, CF75, CF85 Series . Manual - part 928

©

200423

3-61

Removal and installation

BRAKE SYSTEM AND COMPONENTS

ΧΦ65/75/85 series

6

5

3.

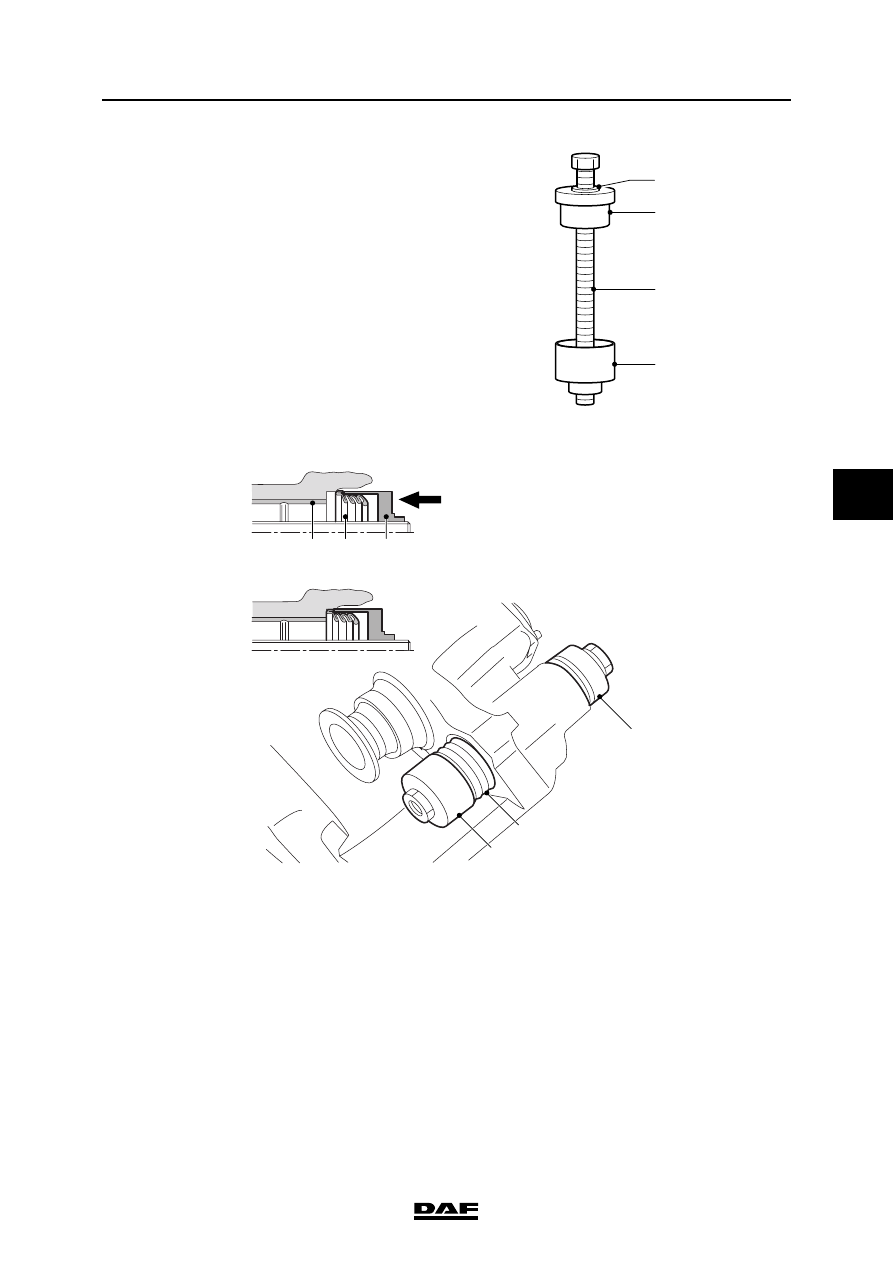

Assemble a press from the special tool set

(DAF no. 1329495). To do this, use T7, T10,

T8 and a washer.

4.

Place a new bellows (3) in the sleeve (5)

of the assembled press.

5.

Place the press and bellows in the bore

of the brake calliper. Hand-tighten the

press (6).

6.

Tighten the press (6) to the specified torque.

See "Technical data". Remove the press.

1

T8

T10

T7

R600761

5

3

4

5

3

6

R600724