DAF CF65, CF75, CF85 Series . Manual - part 420

©

200416

4-3

Inspection and adjustment

CE ENGINE FUEL SYSTEM

ΧΦ65/75/85 series

4

2

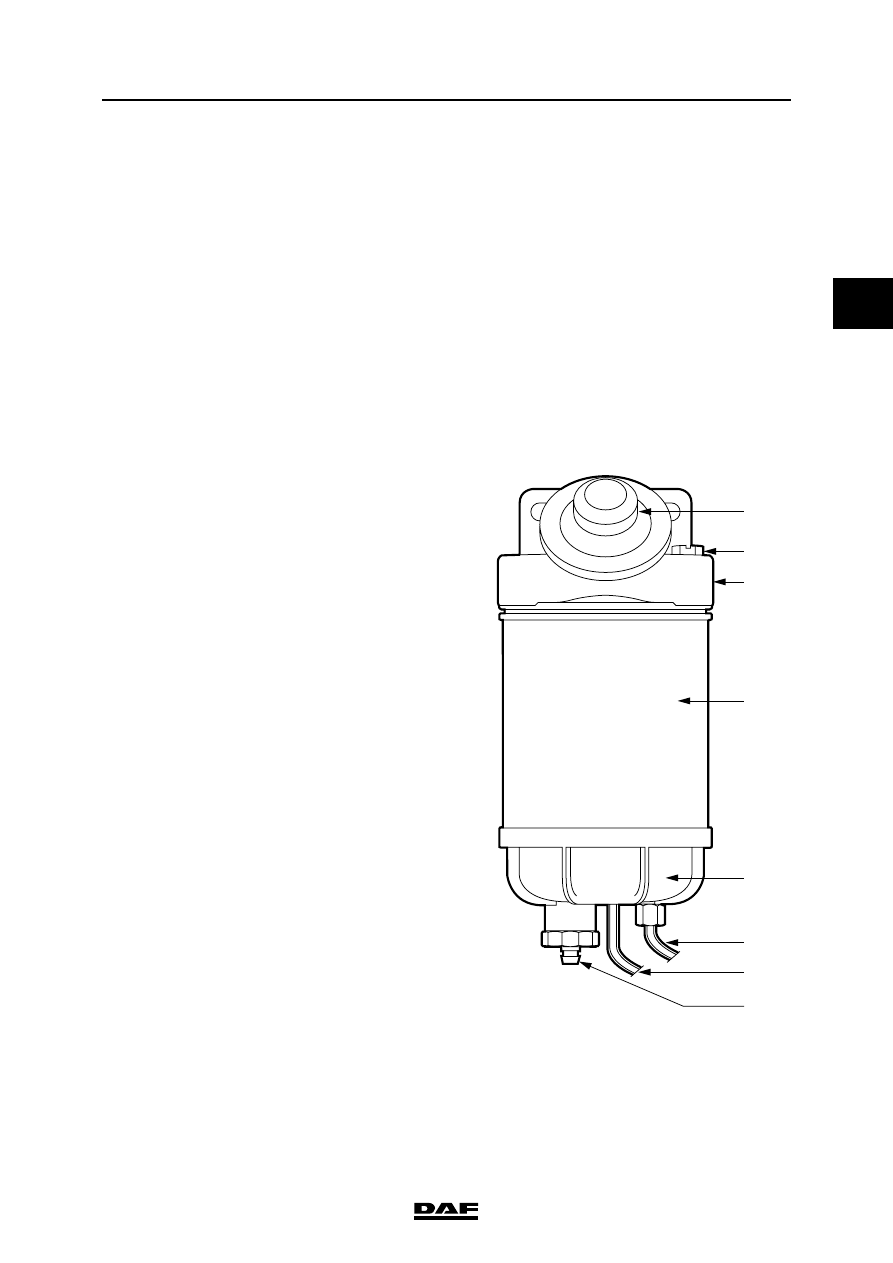

4.2 VENTING THE FUEL SYSTEM

When venting the fuel system, a

quantity of fuel will escape. Collect

the fuel and avoid the risk of fire.

Stop pumping as soon as a

resistance is felt. If you continue

pumping, the fuel system may

become internally damaged.

Note:

When the primer pump is used, the fuel system

will be automatically vented. Air will be fed back

to the tank through the return line.

Racor fuel prefilter/water separator

1.

Open the vent plug (2) a couple of turns.

2.

Pump the primer pump (1) until fuel comes

out of the vent plug (2).

3.

Close the vent plug (2).

4.

Use the primer pump until a clearly higher

resistance is felt.

}

}

1

2

3

4

5

7

6

8

i400356