Content .. 1162 1163 1164 1165 ..

DAF CF65, CF75, CF85 Series . Manual - part 1164

©

200423

3-39

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΧΦ75 series

5

3.41 CHECKING THE CENTRAL AXLE OF THE TANDEM AXLE UNIT FOR LEAKS

1.

Visually inspect the central axle for leaks.

3.42 INSPECTION OF OIL LUBRICATED WHEEL HUBS FOR LEAKS

1.

Check the wheel hubs for leaks.

Note:

If leaks occur in the oil lubricated wheel hubs,

the wheel hub should be refilled to the

correct level - once the leak has been

repaired, see chapter: "Draining and filling".

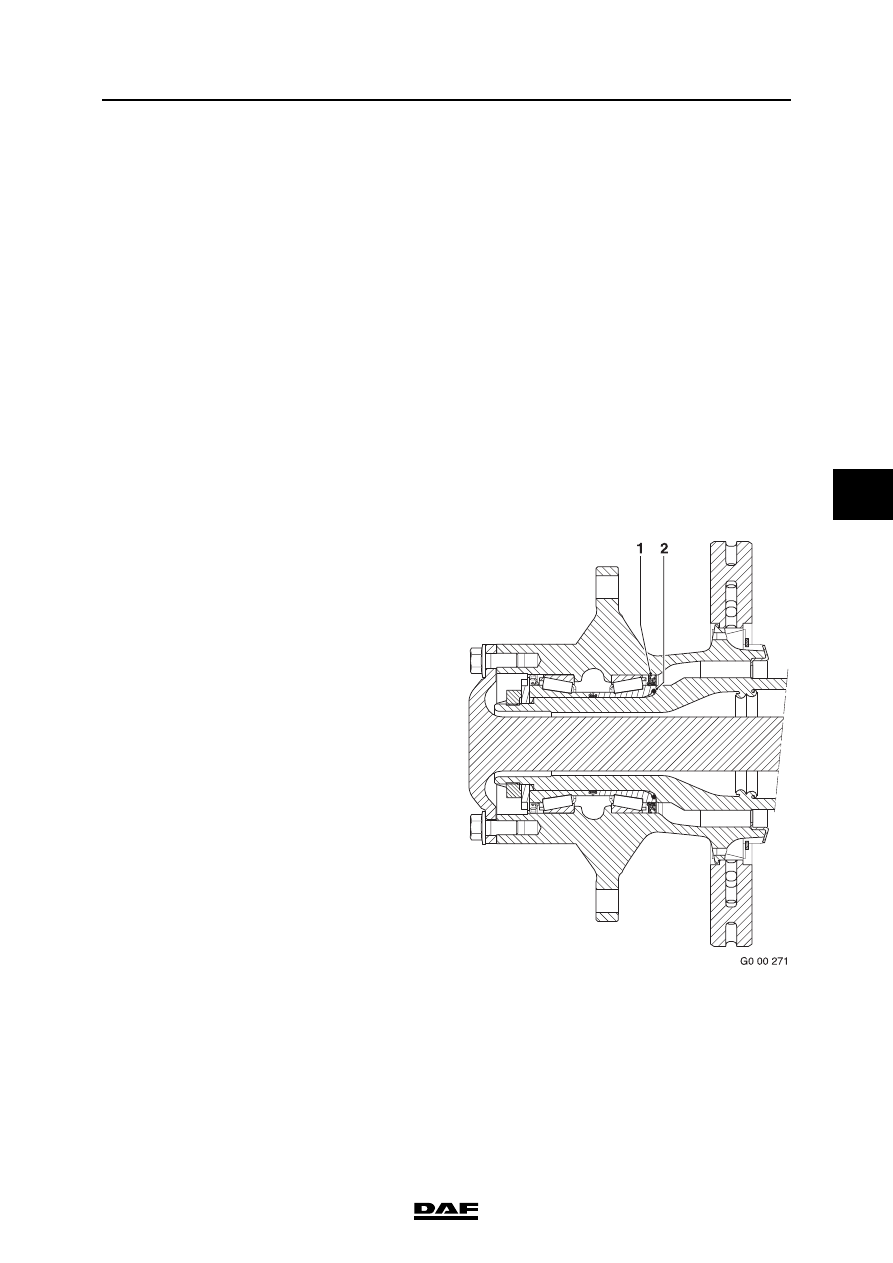

3.43 CHECKING THE GREASED WHEEL HUBS FOR LEAKS

1.

Check the wheel hubs for leaks.

Note:

If there are serious grease marks on the brake

disc side of the wheel hub, this could indicate

excessive use of assembly grease on new or

recently assembled wheel hubs.

On wheel hubs that have not been assembled

recently, serious grease marks could indicate a

leak in the seal (1). This means that the entire hub

unit must be replaced.

Serious oil leakage on the driven rear axle hubs

could indicate that the O-ring (2) is not sealing

correctly.

If there is an oil leak the hub unit should be

dismantled to remedy the problem.