Content .. 1061 1062 1063 1064 ..

DAF CF65, CF75, CF85 Series . Manual - part 1063

©

200424

2-1

General

HYDRAULIC LIFTING GEAR

ΧΦ65/75/85 series

8

9

2. GENERAL

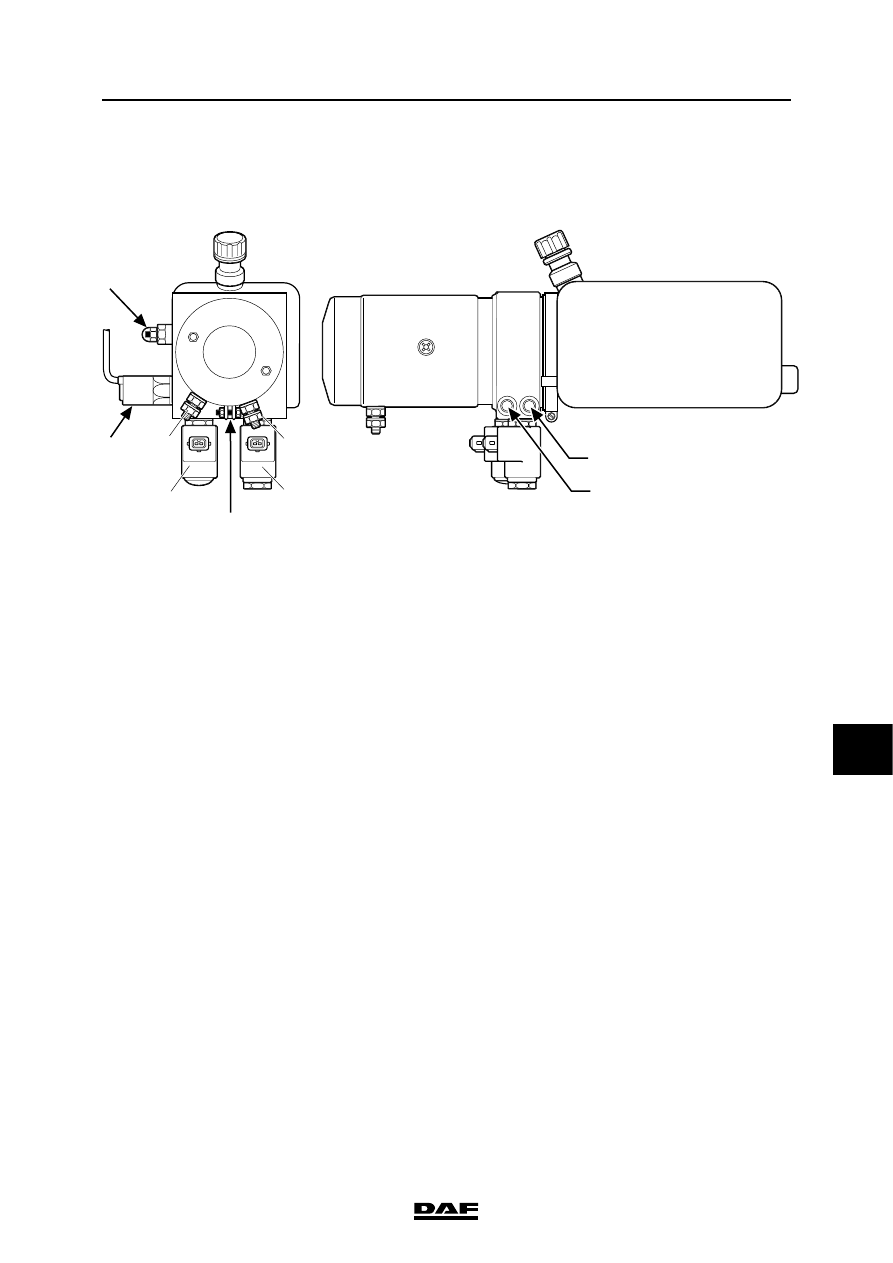

2.1 LOCATION OF COMPONENTS

Relays, diodes and fuse

The relay, diodes and fuse that have a bearing on

the lifting gear of the trailing axle are stored in a

watertight box.

This box is fitted on the inside of the chassis on

the chassis main member.

A

B

1

2

3

4

5

6

7

A8 00 247

1.

Pressure switch

2.

Pressure relief valve

3.

4/2 solenoid valve (lift trailing axle)

4.

2/2 solenoid valve (lower trailing axle)

5.

Built-in non-return valve

6.

+ connection point (D1E1)

7.

- connection point (D2E2)

A.

Line connection (delivery line while

lowering)

B.

Line connection (delivery line while lifting)

(The characters are imprinted on the

pump unit)