Content .. 1306 1307 1308 1309 ..

Chevrolet Silverado / GMC Sierra. Manual - part 1308

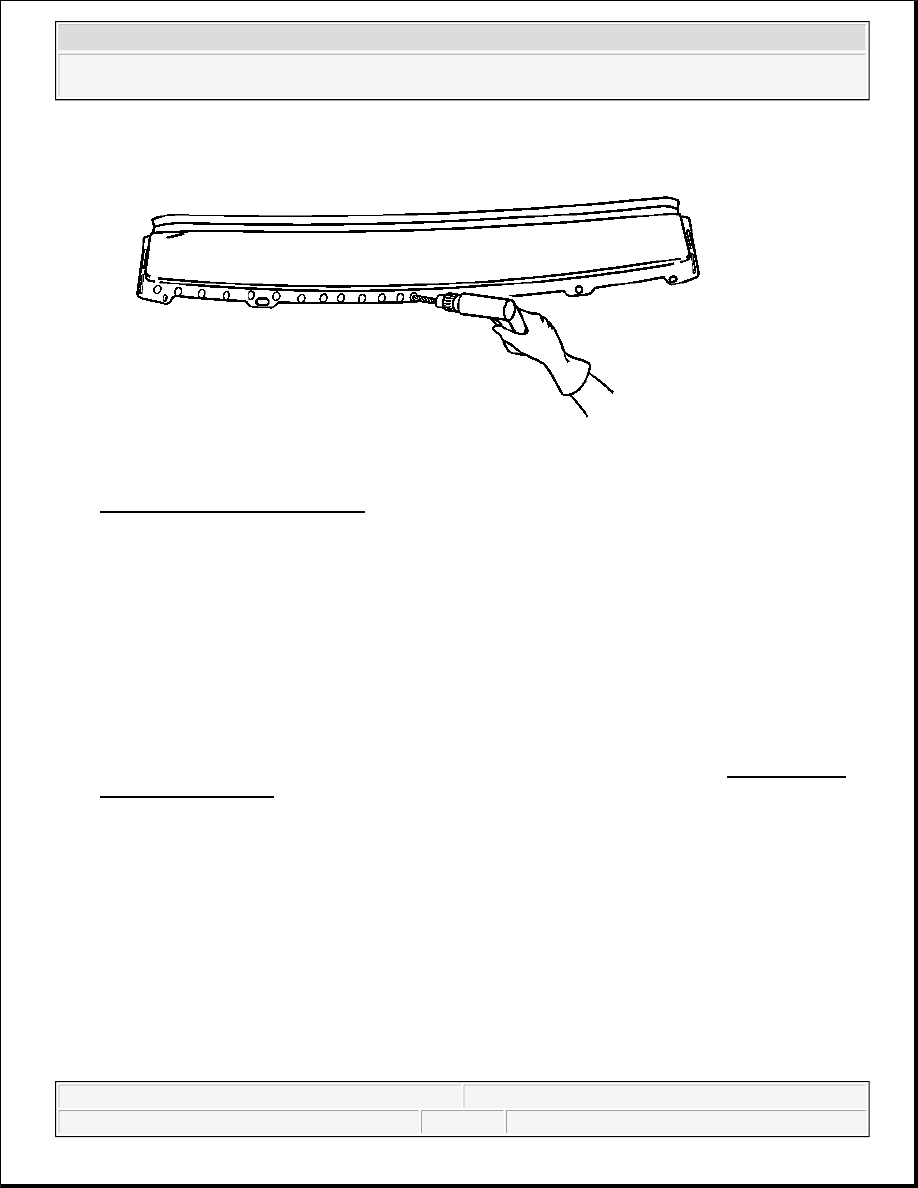

Fig. 144: Drilling Plug Weld Holes

Courtesy of GENERAL MOTORS CORP.

1. Drill 8 mm (5/16 in) plug weld holes in the service part as necessary in the locations noted from the

original panel.

2. Prepare all attachment surfaces as necessary.

3. Prepare all mating surfaces as necessary.

4. Apply GM-approved Weld-Thru Coating or equivalent to all mating surfaces. Refer to Anti-Corrosion

Treatment and Repair .

5. Position the service part. Clamp in place.

IMPORTANT: If the location of the original plug weld holes can not be determined,

space the plug weld holes every 40 mm (1 1/2 in) apart. Where structural

adhesive was present, space the plug weld holes every 20 mm (3/4 in)

apart.

2008 Chevrolet Silverado 1500

2008 ACCESSORIES & EQUIPMENT Collision Repair - - Cab & Chassis Sierra, Cab & Chassis Silverado, Sierra &

Silverado

Microsoft

Friday, August 21, 2009 2:21:01 PM

Page 158

© 2005 Mitchell Repair Information Company, LLC.