Yanmar diesel tractor EF494T. OPERATOR'S MANUAL - part 16

EF494T OM

60

7. Fuel

line

Fuel filter

Replace fuel filter every 300 hours.

Replacing

(1) Close fuel cock on water separator.

(2) Remove the cartridge by turning anticlockwise.

(3) Apply a little oil on the rubber ring on the new

cartridge. Mount the cartridge by hand first and tight it

with filter wrench.

(4) Open the cock and bleed the air from the fuel.

IMPORTANT

Use genuine element. Otherwise, FIE (Fuel

Injection Pump) will be in trouble, premature

wearing of plunger. It may cause a hard start of

the engine.

(A) Fuel filter

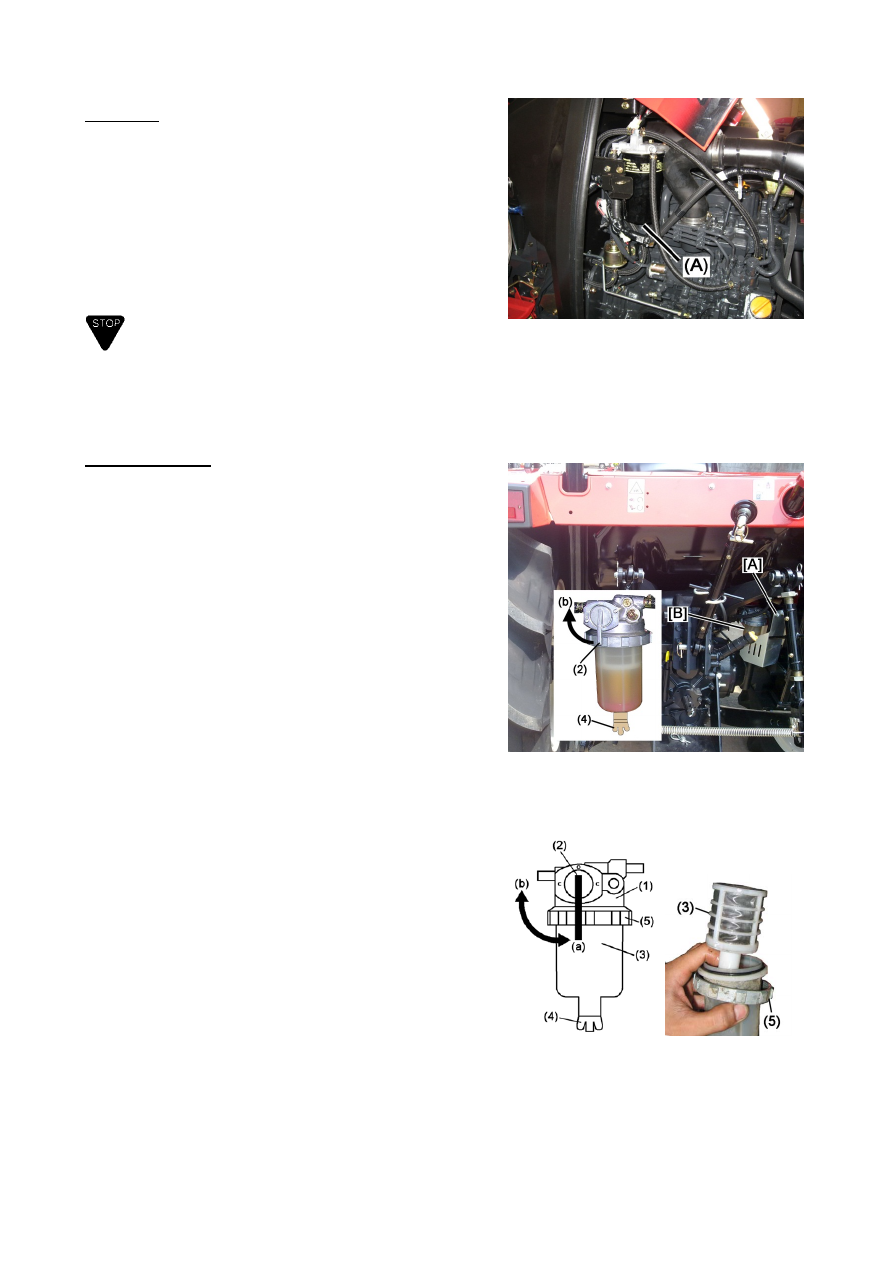

Water separator

Removing water from water separator

The water separator separates water from fuel oil. Water

accumulates in the fuel tank by formation of dew. The

water in fuel may damage the fuel injection pump when the

water gets in the plunger and barrel.

Drain the water accumulated in the water separator

regularly, every 100 hours or shorter if much water in the

bowl.

(1) Remove the cover [A].

(2) Turn the fuel cock (2) to (b) to close.

(3) Turn the drain cock (4) to drain the water.

[A] Cover

[B] Water separator

(2) Fuel cock

(4) Drain cock

(b) Close

Cleaning water separator element

Clean the element regularly, every 300 hours or shorter

when it gets dirty.

(1) Turn fuel cock (2) to (b) to close the fuel cock.

(2) Turn retaining ring (5) to remove ring and detach

water separator bowl.

(3) Clean strainer (3), inside of bowl.

(4) Reinstall strainer, bowl and retaining ring.

(5) Turn fuel cock to (a) to open the fuel cock.

NOTE:

Strainer is made of plastic and be careful not to damage. It

is suggested to clean it with used toothbrush or soft brush.

If strainer was damaged, replace it with a new genuine part.

(1) Water separator (2) Fuel cock

(3) Strainer (4) Drain cock

(5) Retainer ring

(a) Open

(b) Close