TM 10-8400-203-23&P. Manual - part 19

TM

10-8400-203-23&P

0021

BASIC TROUSER REPAIR – CONTINUED

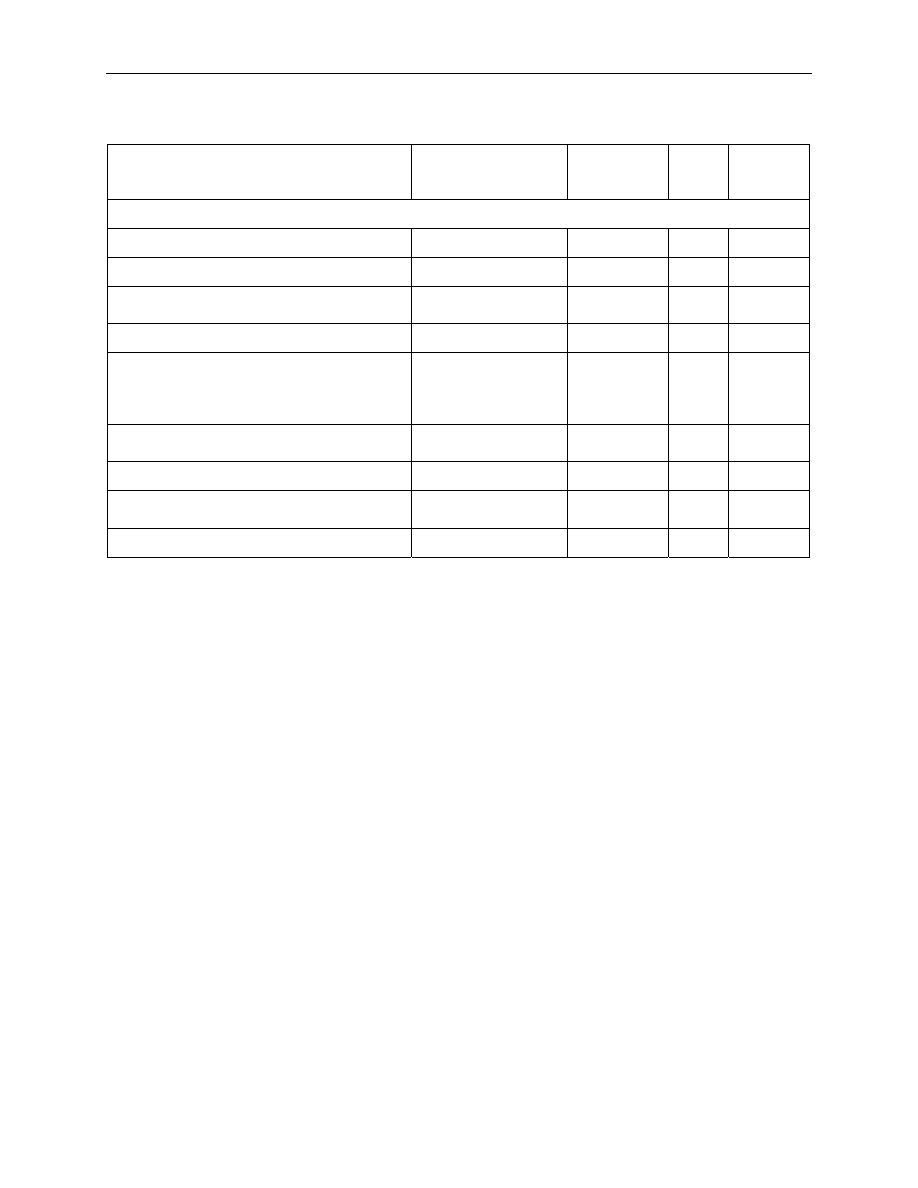

Table 1. BASIC Sewing Requirements.

COMPONENT

RECOMMENDED

SEWING MACHINE

(CODE SYMBOL)

STITCHES

PER INCH

TYPE

THREAD

SIZE

BALLISTIC TROUSERS

General

Medium Duty

8 to 10

301

E

Bar Tack

Bar Tack

28

301

E

Overedge

Medium Duty

6 to 8

502

503

E

Hook and loop fastener tape

Medium Duty

9 to 11

301

E

Overedge ballistic insert

Medium Duty

6 to 8

502

503

504

505

E/F

Sewing ballistic inserts into the shell

components

Medium Duty

6 to 8

301

F

Sewing inner or outer shell

Medium Duty

9 to 11

301

E

Assemble wide and narrow upper leg

and lower leg strap

Medium Duty

9 to 11

301

E

Assemble shoulder pad

Medium Duty

9 to 11

301

E

Outer Shell Replacement

The outer shell, including the hook and loop fastener tape, may be replaced it is badly tom, worn or

damaged.

1. If the protective trousers exhibit holes or tears, seam openings or frayed areas larger than 3 inches,

or the hook and loop fasteners are inoperative, replace the entire shell section by removing the

ballistic inserts.

2. Cut material for new outer shell to dimensions specified in Table 2.

3. Sew as specified in Table 1.

4. If the outer shell is to be removed and replaced, it is important that the label containing the size,

National Stock Number, and cleaning instructions be retained and stitched to the new shell.

5. Check the ballistic insert size markings for legibility and remark if necessary.

6. If the label is illegible, replace it with a new one.