TM 10-8400-203-23&P. Manual - part 20

TM

10-8400-203-23&P

0022

REPAIR – CONTINUED

Replace Hardware

1. Remove the chinstrap retention system.

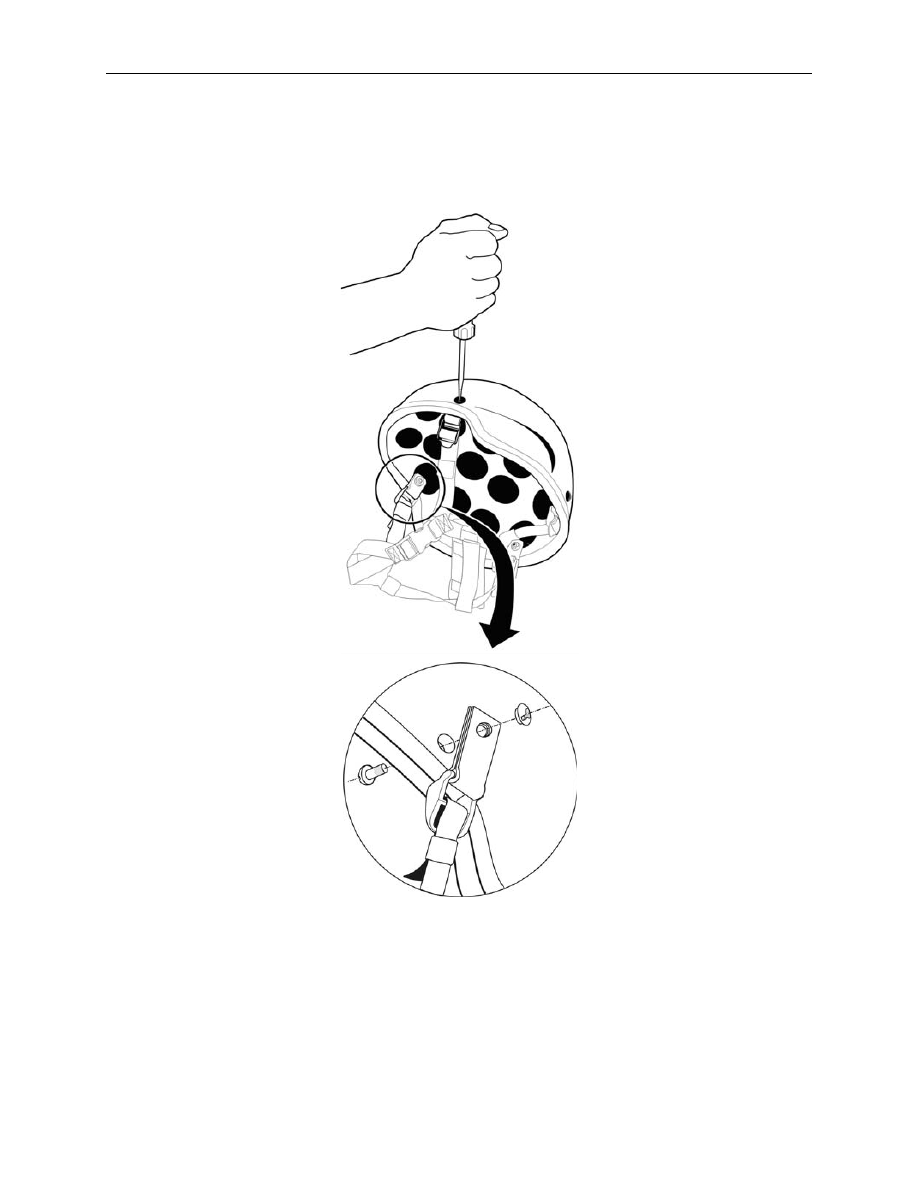

2. Remove the screw with standard flathead screwdrivers and lift the attachment tab assembly. Note

orientation of the attachment tab assembly before removal (Figure 3).

Figure 3. Replacing Hardware.

3. Install new attachment tab assembly in the same orientation as when removed. Replace screw and

nut.

4. Inspect the screws to ensure tightness. If loosening persists, use the thread-locking compound.

END OF TASK