Yamaha XV1700P, XV1700PC. Service Manual - part 29

7 - 12

–

+

ELEC

CHECKING THE BULBS AND BULB SOCKETS

EAS00732

CHECKING THE BULBS AND

BULB SOCKETS

Check each bulb and bulb socket for damage

or wear, proper connections, and also for con-

tinuity between the terminals.

Damage/wear

→

Repair or replace the

bulb, bulb socket or both.

Improperly connected

→

Properly connect.

No continuity

→

Repair or replace the bulb,

bulb socket or both.

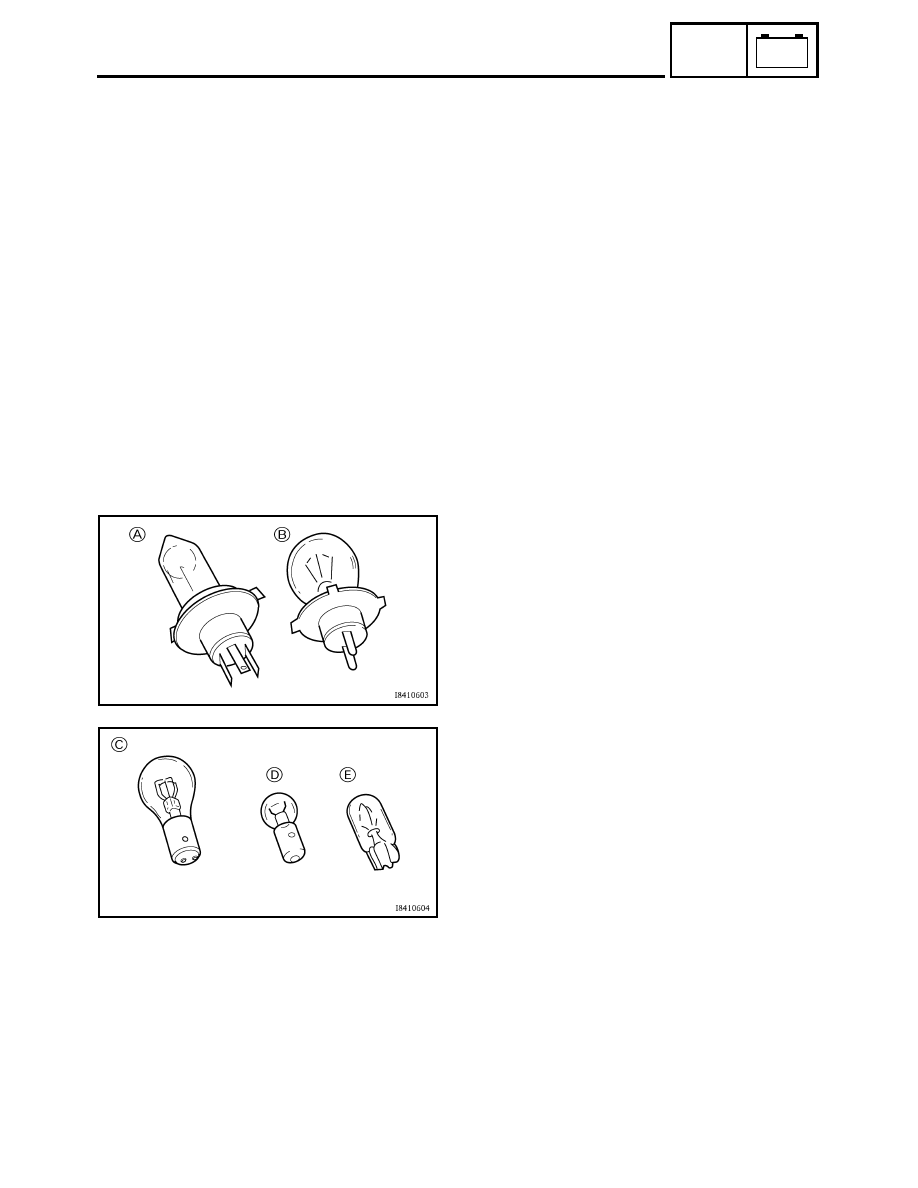

TYPES OF BULBS

The bulbs used on this motorcycle are shown

in the illustration on the left.

• Bulbs

A

and

B

are used for the headlights

and usually use a bulb holder that must be

detached before removing the bulb. The

majority of these types of bulbs can be

removed from their respective socket by

turning them counterclockwise.

• Bulbs

C

is used for turn signal and tail/

brake lights and can be removed from the

socket by pushing and turning the bulb

counterclockwise.

• Bulbs

D

and

E

are used for meter and indi-

cator lights and can be removed from their

respective socket by carefully pulling them

out.

CHECKING THE CONDITION OF THE

BULBS

The following procedure applies to all of the

bulbs.

1. Remove:

• bulb