Yamaha XV1700P, XV1700PC. Service Manual - part 30

7 - 28

–

+

ELEC

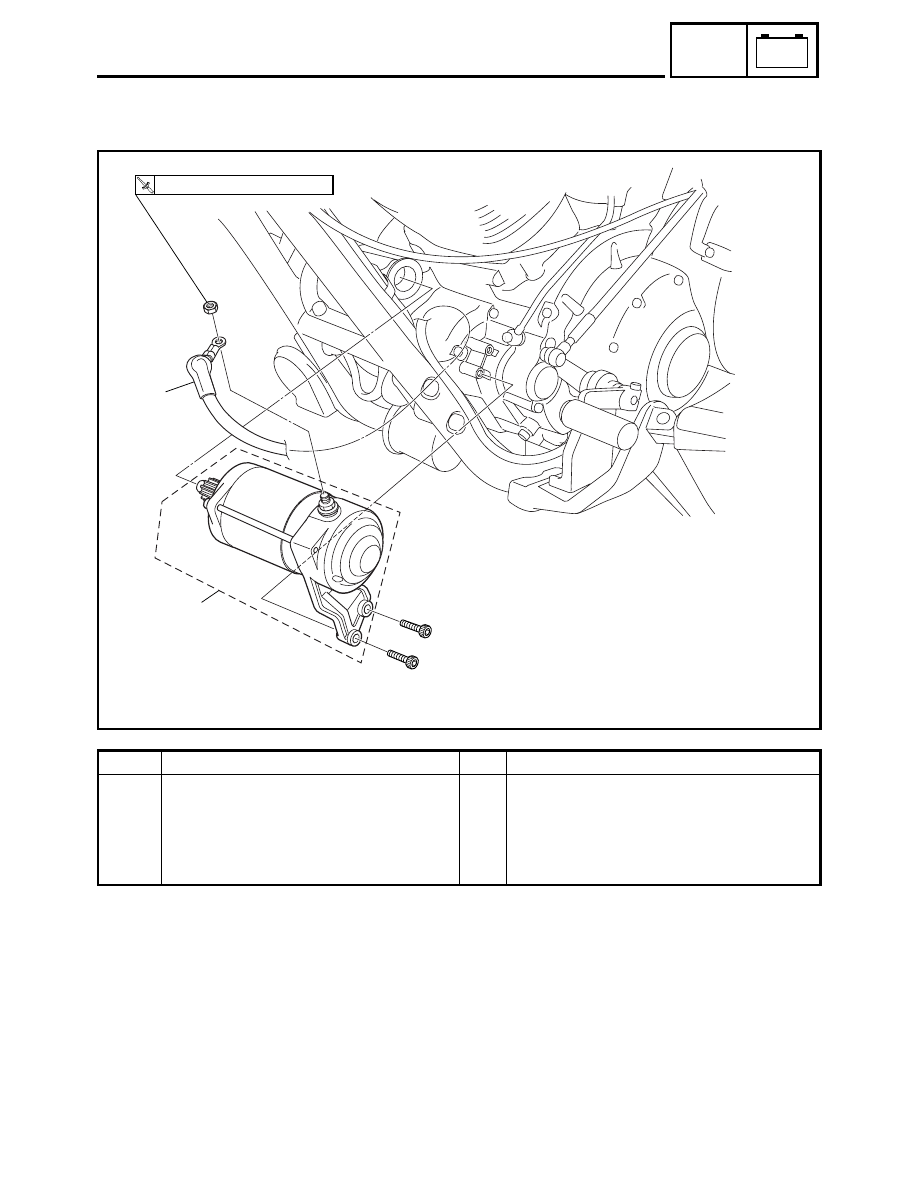

STARTER MOTOR

EAS00767

STARTER MOTOR

2

1

T

R

.

.

5 Nm (0.5 m

•

kg, 3.6 ft

•

Ib)

Order

Job/Part

Q’ty

Remarks

Removing the starter motor

Remove the parts in the order listed.

1

Starter motor lead

1

2

Starter motor assembly

1

For installation, reverse the removal

procedure.