Yamaha XV1700P, XV1700PC. Service Manual - part 27

6 - 25

FI

FUEL INJECTION SYSTEM

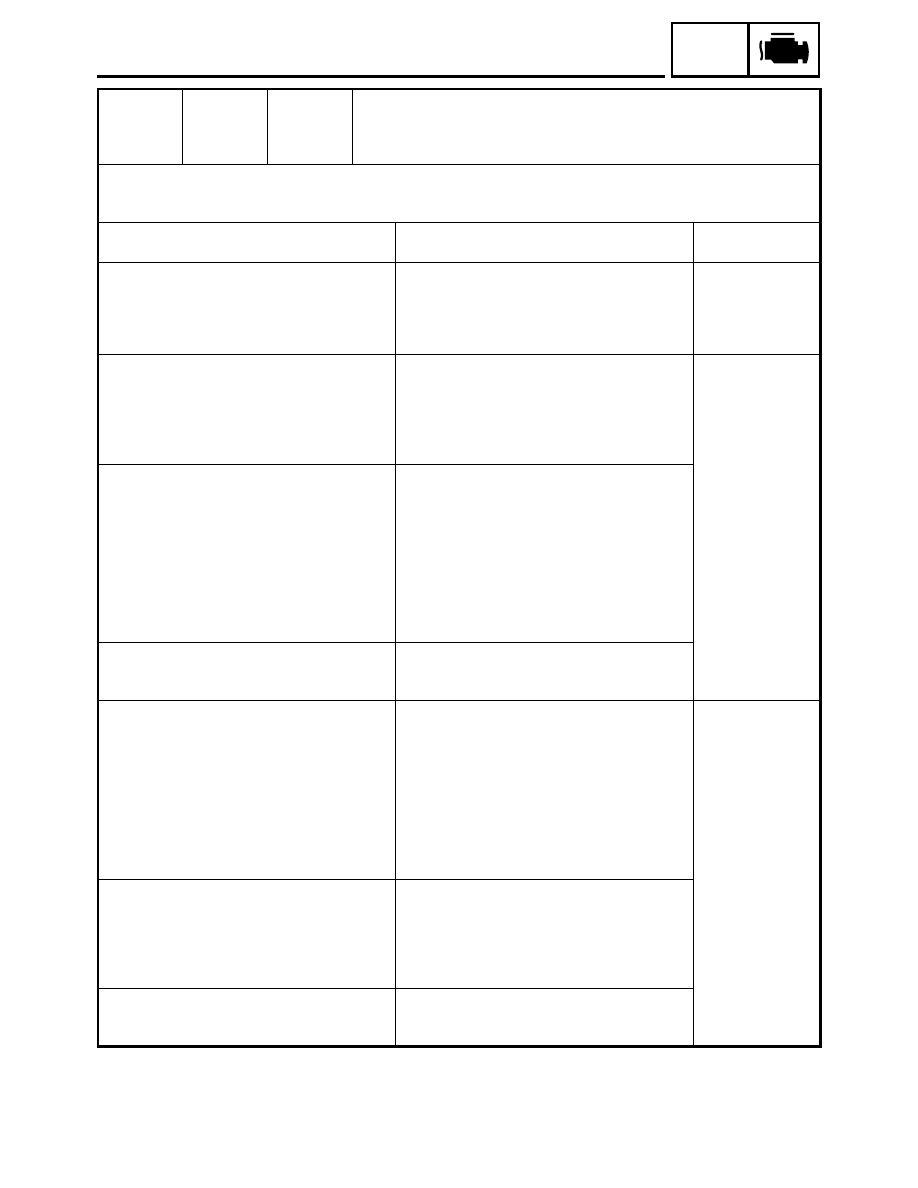

Code No.

26

Symptom

1 Intake air pressure sensor 2 - pipe system malfunction (clogged or

detached hose).

2 Intake air pressure sensor 2 - open or short circuit detected.

3 Stuck throttle position sensor detected.

Used diagnostic code

No. 04 (intake air pressure sensor 2)

No. 01 (throttle position sensor)

No. 02 (atmospheric pressure sensor)

Inspection operation item and probable cause Operation item and countermeasure

Reinstatement

method

1.Common to 1, 2, and 3:

Connected state of connector

Inspect the coupler for any pins that may

have pulled out.

Check the locking condition of the coupler.

If there is a malfunction, repair it and connect it

securely.

Intake air pressure sensor coupler

Main wiring harness ECU coupler

Reinstated by

starting the engine

and operating it at

idle.

2-1.Intake air pressure sensor hose detached,

clogged, kinked, or pinched.

Intake air pressure sensor malfunction at

intermediate electrical potential.

Atmospheric pressure sensor malfunction

at intermediate electrical potential.

Repair or replace the sensor hose.

Inspect and repair the connection.

Replace it if there is a malfunction.

See page 6-25

Reinstated by

starting the engine

and operating it at

idle.

2-2.Open or short circuit in wiring harness or

sub lead.

Repair or replace if there is an open or short

circuit.

Main wiring harness

Black/Blue - Black/Blue

Pink/White - Pink/White

Blue - Blue

Sub lead

Black/Blue - Black/Blue

Pink/White - Pink/White

Blue - Blue

2-3.Defective intake air pressure sensor.

Replace if defective.

Refer to “FUEL INJECTION SYSTEM” in

chapter 7.

3-1.Open or short circuit in wiring harness or

sub lead.

Repair or replace if there is an open or short

circuit.

Main wiring harness

Black/Blue - Black/Blue

Yellow - Yellow

Blue - Blue

Sub lead

Black/Blue - Black/Blue

Yellow - Yellow

Blue - Blue

Reinstated by

starting the engine,

operating it at idle,

and then by racing

it.

3-2.Throttle position sensor lead wire open cir-

cuit output voltage check

(B/L - Y)

Black/Blue - Yellow

Open circuit item:

Output voltage

Ground wire open circuit:

5 V

Output wire open circuit:

0 V

Power supply wire open circuit: 0 V

Check for open circuit and replace the throttle

position sensor.

3-3.Defective throttle position sensor.

Replace if defective.

Refer to “FUEL INJECTION SYSTEM” in

chapter 7.