Yamaha XV1700P, XV1700PC. Service Manual - part 26

6 - 9

FI

FUEL INJECTION SYSTEM

TROUBLESHOOTING

Diagnosis mode troubleshooting 1 (self-diagnostic malfunction detected)

By entering a diagnostic code in the ECU through the use of the “SELECT” and “RESET” buttons on

the tachometer, the sensor output values can be displayed and the actuators can be operated in

accordance with the code that has been entered.

The technician determines whether or not the operation is normal by verifying the values displayed

on the tachometer or the operating conditions of the actuators. These modes can be used to detect

and check the problems that are otherwise difficult to detect in the diagnosis mode.

Basic operation procedure

Operation preparation

• Verify the self-diagnostic fault code number that is displayed on the meter.

• Based on the self-diagnostic fault code number, select the applicable sensor or actuator from the

diagnostic code table.

• If a diagnostic code is available, proceed with the operation procedure given below in order to

verify the operating conditions of the applicable sensor or actuator.

Operation procedure (make sure to turn “OFF” the main switch upon completing the operation prep-

aration)

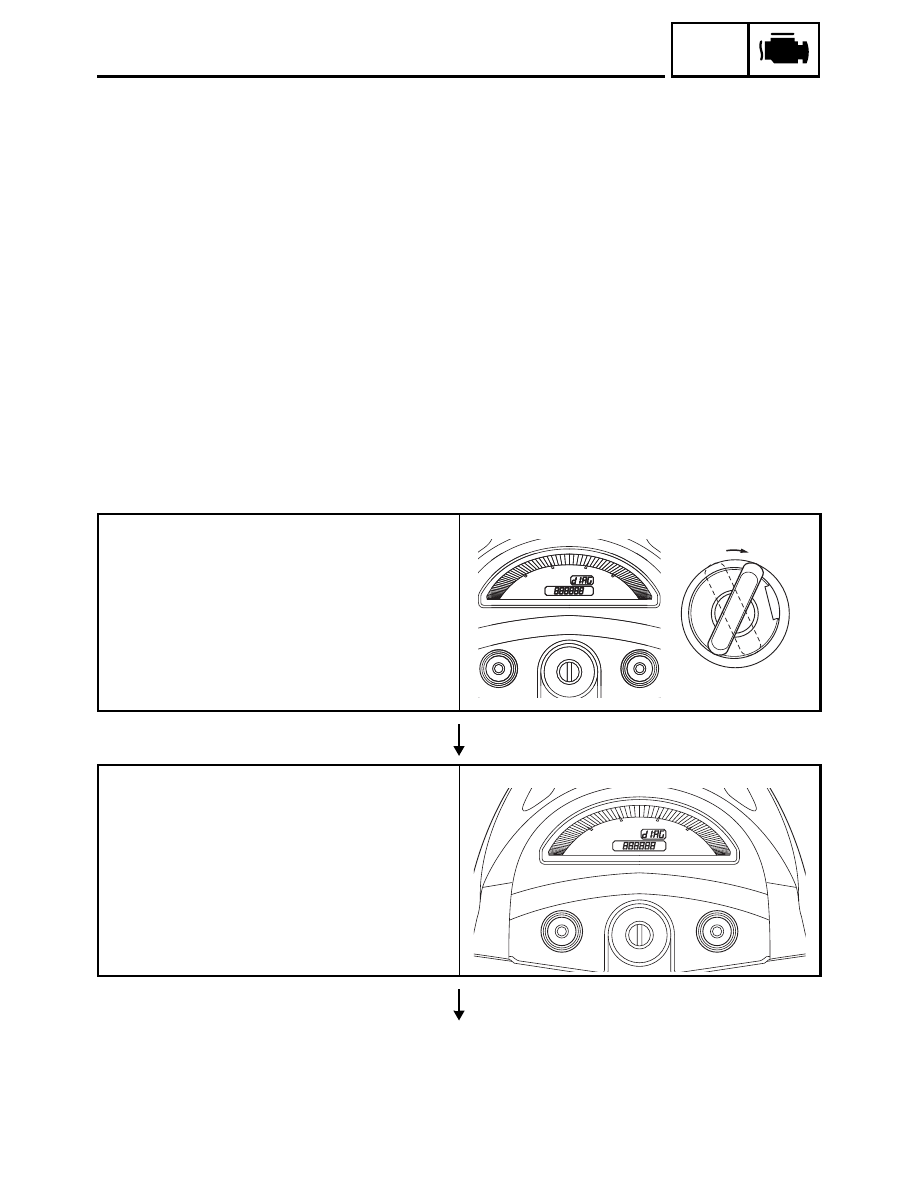

Setting the ECU in the diagnosis mode

1. While keeping the “SELECT” and “RESET”

buttons pressed simultaneously, turn “ON”

the main switch

1

(keep them pressed for

8 seconds or more).

* Letters “dIAG” appear on the clock LCD.

Selecting the diagnosis mode

After “dIAG” appears as a result of pressing

the “SELECT” button, simultaneously press

the “SELECT” and “RESET” buttons for 2 sec-

onds or more to execute the selection.

OFF

ON

TRIP

km

mile

TRIP

km

mile

0D0

T

1

TRIP

km

mile

0D0

SELECT

RESET