Yamaha XV1700P, XV1700PC. Service Manual - part 24

5 - 102

ENG

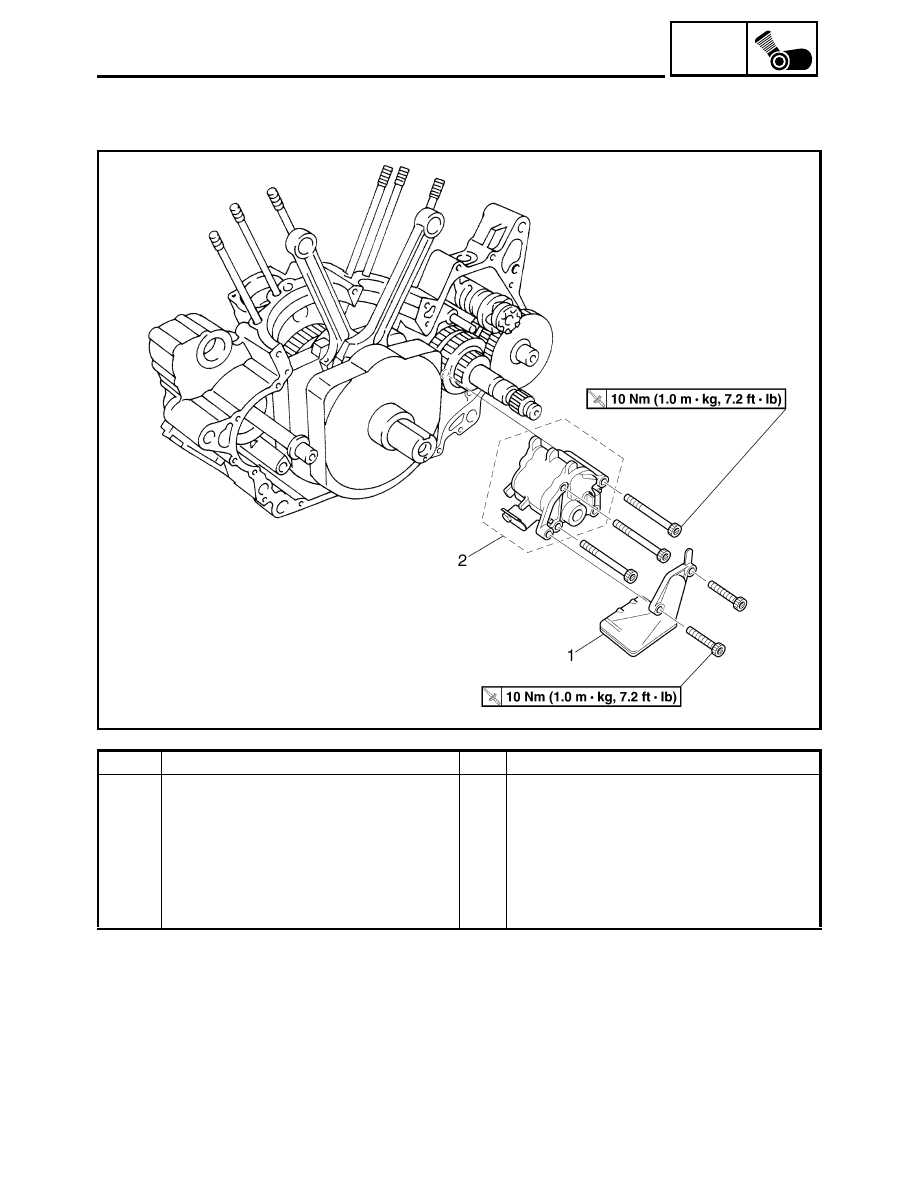

ENGINE OIL PUMP

EAS00356

ENGINE OIL PUMP

Order

Job/Part

Q’ty

Remarks

Removing the engine oil pump

Remove the parts in the order listed.

Crankcase

Separate.

Refer to “CRANKCASE”

1

Oil strainer

1

2

Engine oil pump assembly

1

For installation, reverse the removal

procedure.